Multilayer tablet fuse and method of manufacturing the same

A multi-layer chip, fuse technology, applied in fuse manufacturing, emergency protection devices, electrical components, etc., can solve the problems of not being widely used, large equipment investment, long production cycle, etc., to achieve shortened production cycle, equipment The effect of low investment and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Preparation of three-layer chip fuse

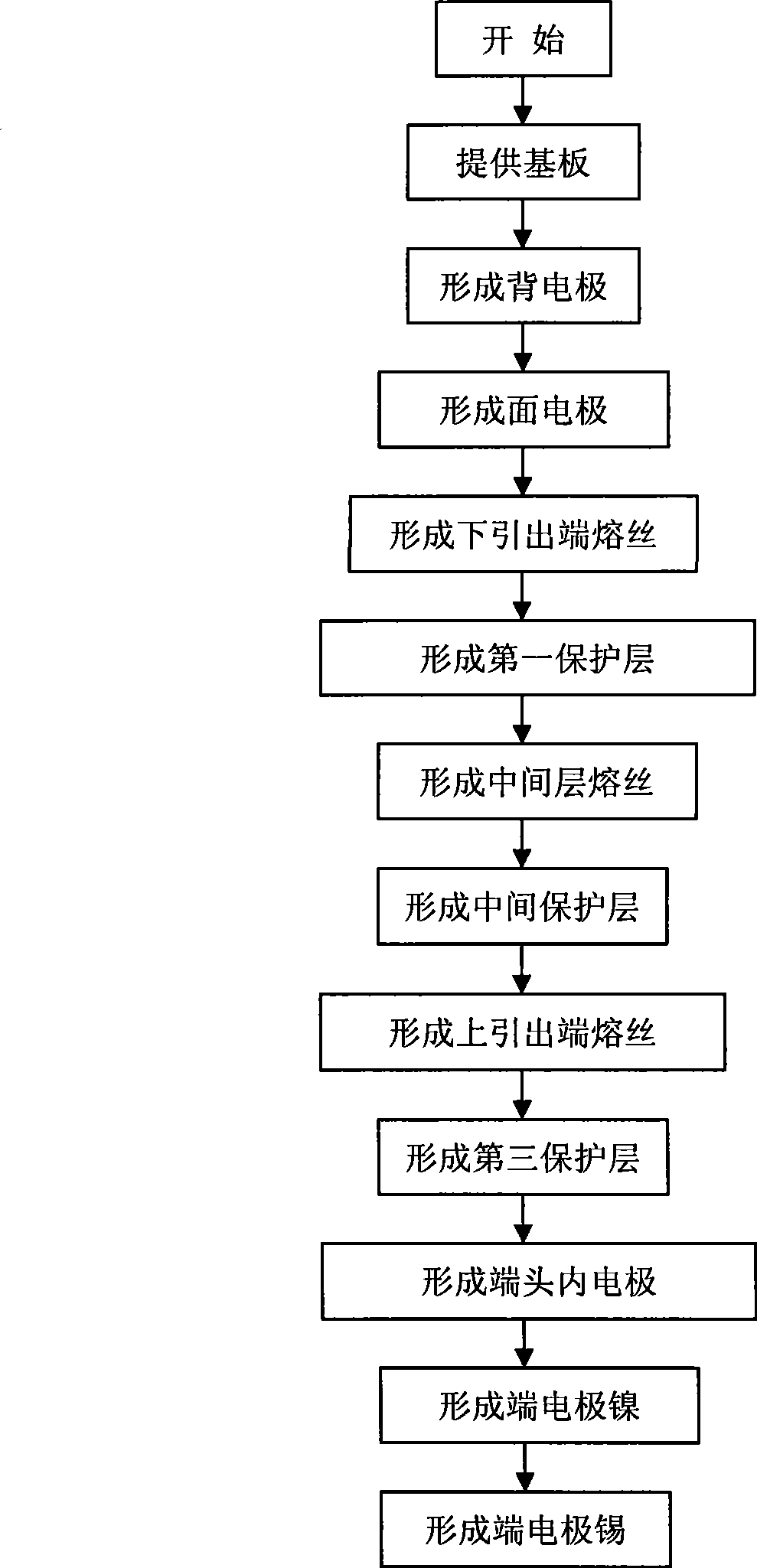

[0030] The preparation process is as figure 1 As shown, the specific operation is as follows:

[0031] One: Provide substrate 1, the material is mainly alumina or steatite porcelain, such as figure 2 ;

[0032] Two: Form the back electrode

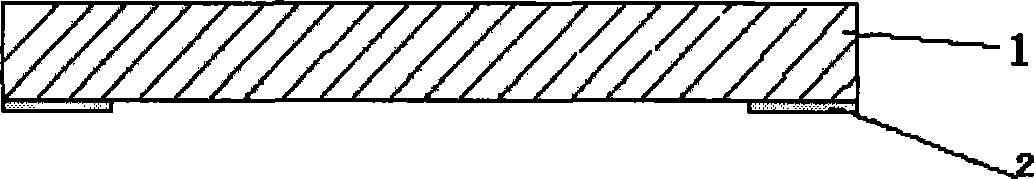

[0033] Such as image 3 As shown, on the left and right sides of the lower surface of the substrate 1, the back electrode pattern 2 is formed by screen printing conductive paste, and the material of the conductive paste contains silver;

[0034] 3. Dry in a drying oven (temperature: 150°C, time: 15min)

[0035] Four: Form the front electrode

[0036] Such as Figure 4 As shown, the front electrode 3 is formed by screen printing conductive paste on the front of the substrate 1, and the material contains silver or silver palladium;

[0037] 5. Dry in a drying oven (temperature: 150°C, time: 15min)

[0038] 6. Put it into the sintering furnace for sintering (maximum temperatur...

Embodiment 2

[0064] The S1206-S-0.5A product was made through the above-mentioned Example 1, and tested according to the inspection items and technical requirements of GB9364.4-2006 and GB9364.1-1997, which fully met the performance requirements, especially the anti-surge test of 10 times the current Compared with the traditional single-layer chip fuse, the results are greatly improved. For the convenience of explanation, the comparison table of the above tests is listed:

[0065] Table 1: Aging test comparison

[0066]

[0067] Note: The test conditions are: take 20 samples each, pass the rated current for 200h at a temperature of 25°C and a humidity of 40%, and make the fusing time of twice the current and ten times the current respectively after the samples are finished.

[0068] Instruments used in this test: BXC-35A fuse tester, DS5062M digital oscilloscope.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com