Novel waterproof air previous polyurethane artificial leather and preparation thereof

A waterproof, breathable, and manufacturing method technology, which is applied to chemical instruments and methods, synthetic resin layered products, textiles and papermaking, etc., can solve the problems of performance degradation and destruction of polyurethane bond structure, etc., and achieve high physical properties, plump hand feeling, Excellent waterproof and breathable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

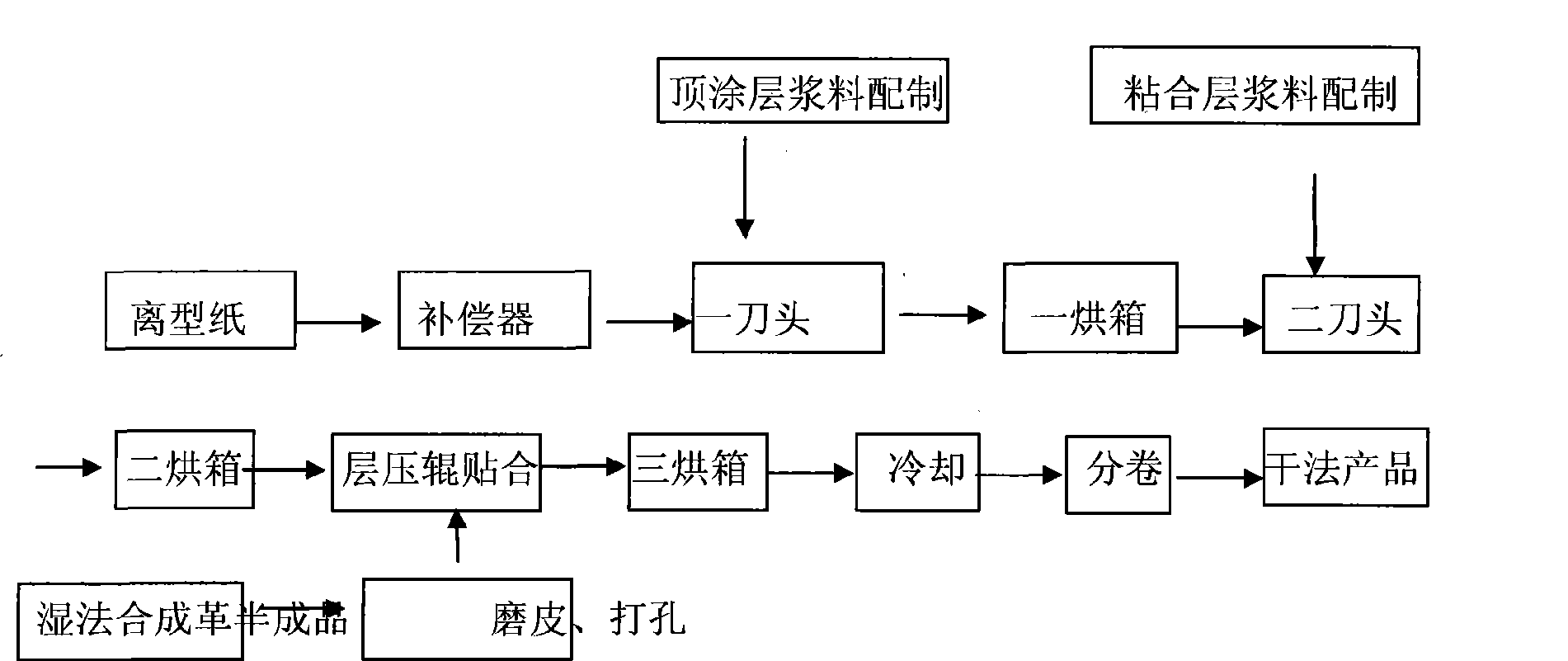

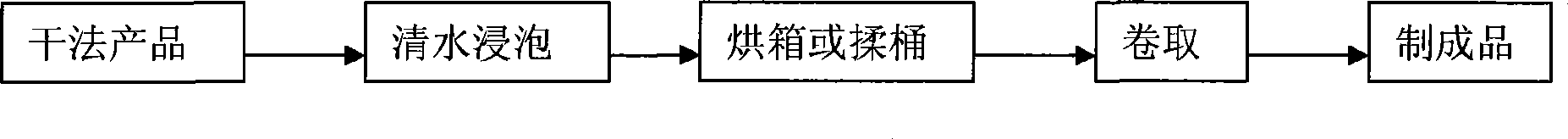

Method used

Image

Examples

Embodiment 1

[0100] (1) Wet slurry preparation (weight ratio):

[0101] Thermoplastic polyurethane elastomer resin (SW-2020RH) 100 parts

[0102] 70 parts of N,N-dimethylformamide (DMF)

[0103] Solvent-based colorant (such as: white paste) 0.5 parts

[0104] 15 parts wood flour

[0105] Anionic surfactant (D-700) 1 part

[0106] 0.5 parts of nonionic surfactant (D-101)

[0107] Water and oil repellant (PF-1108) 2 parts

[0108] Using wet-process synthetic leather production equipment, the prepared thermoplastic wet-process polyurethane slurry is coated on the woven fabric for synthetic leather, and then entered into a coagulation tank for solidification, washed with water and dried to obtain a wet-process synthetic leather semi-finished product.

[0109] (2) Preparation of waterproof and breathable wet-process synthetic leather semi-finished products: using a post-treatment dermabrasion machine, the wet-process synthetic leather semi-finished products prepared by (1) are subjected to...

Embodiment 2

[0132] (1) Wet slurry preparation (weight ratio):

[0133] Thermoplastic polyester polyurethane resin (SW-2020RH) 100 parts

[0134] 60 parts of N,N-dimethylformamide (DMF)

[0135] Solvent-based color paste (black paste) 0.5 parts

[0136] 5 parts wood flour

[0137] Anionic surfactant (D-700) 2 parts

[0138] Nonionic surfactant (D-101) 1 part

[0139] Water and oil repellant (PF-1108) 1 part

[0140] Using wet-process synthetic leather production equipment, the prepared thermoplastic wet-process polyurethane slurry is coated on the non-woven base fabric for synthetic leather, and then enters the coagulation tank to solidify, washed and dried to obtain wet-process synthetic leather semi-finished products.

[0141] (2) Preparation of waterproof and breathable wet-process synthetic leather semi-finished products: using a post-treatment dermabrasion machine, the wet-process synthetic leather semi-finished products prepared in (1) are subjected to dermabrasion treatment to ...

Embodiment 3

[0161] (1) Wet slurry preparation (weight ratio):

[0162] Thermoplastic polyurethane elastomer resin (SW-2020RH) 100 parts

[0163] 70 parts of N,N-dimethylformamide (DMF)

[0164] Solvent-based colorant (such as: white paste) 0.5 parts

[0165] 15 parts wood flour

[0166] Anionic surfactant (D-700) 1 part

[0167] 0.5 parts of nonionic surfactant (D-101)

[0168] Water and oil repellant (PF-1108) 2 parts

[0169] Using wet-process synthetic leather production equipment, the prepared thermoplastic wet-process polyurethane slurry is coated on the woven fabric for synthetic leather, and then entered into a coagulation tank for solidification, washed with water and dried to obtain a wet-process synthetic leather semi-finished product.

[0170] (2) Preparation of waterproof and breathable wet-process synthetic leather semi-finished products: using post-processing punching equipment, the wet-process synthetic leather semi-finished products prepared by (1) are subjected to ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com