Method for rapidly screening oil refining wastewater bioflocculant-producing bacteria

A technology for microbial flocculants and oil refining wastewater, applied in biochemical equipment and methods, microorganisms, microorganisms, etc., can solve problems such as large workload, low screening efficiency, and uncertain screening targets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

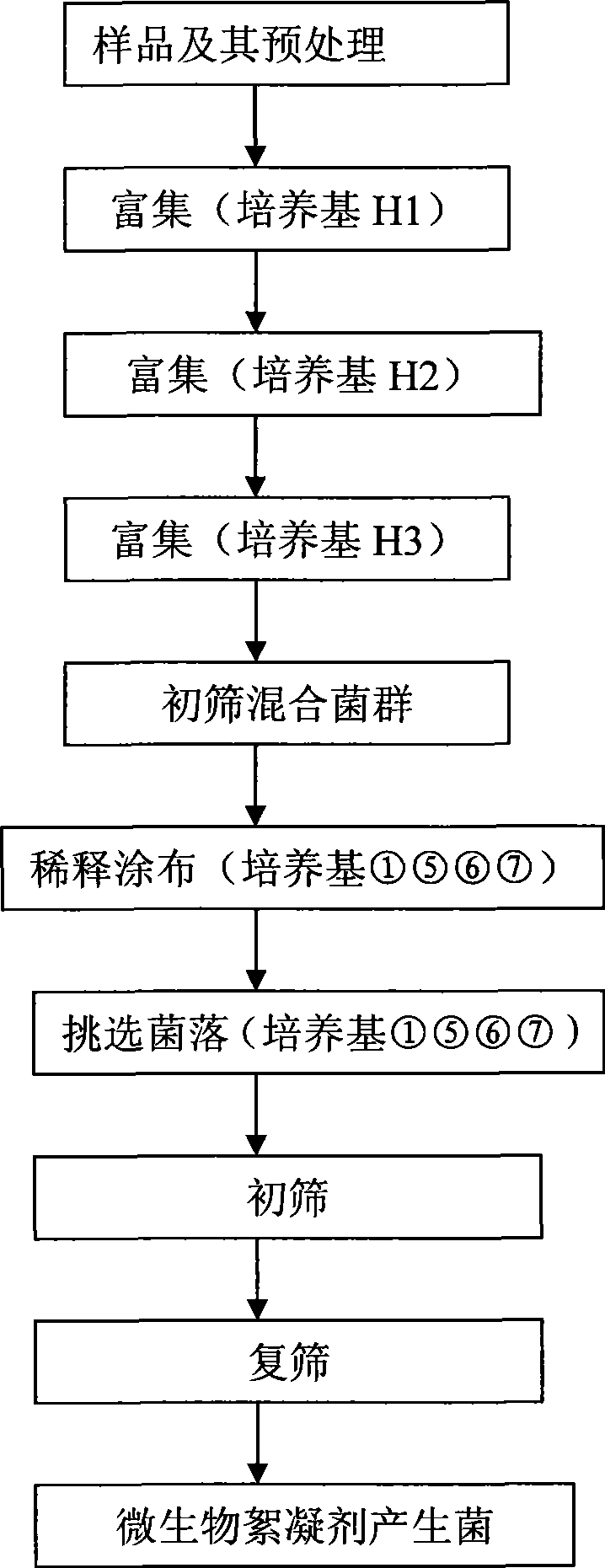

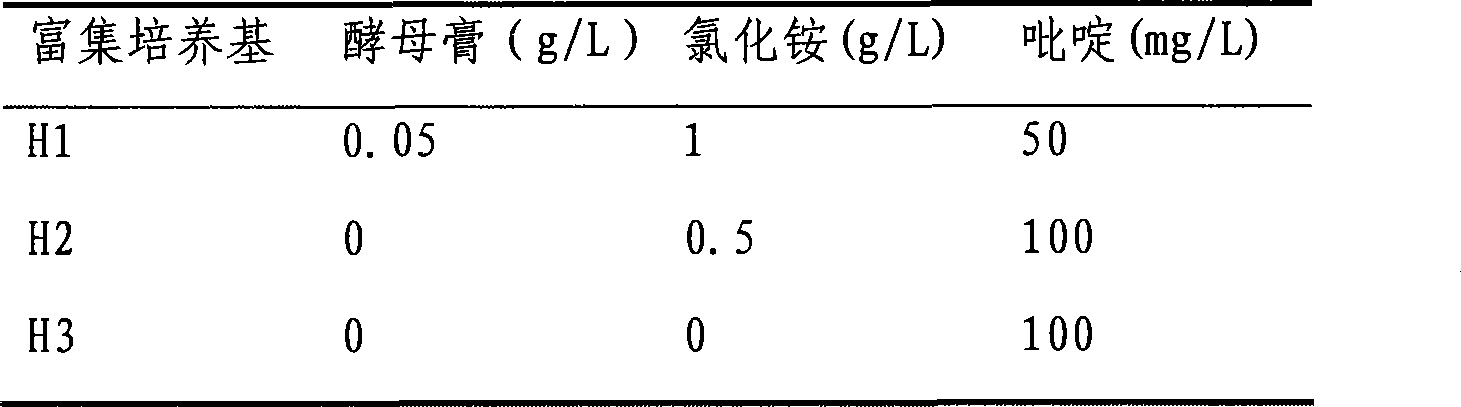

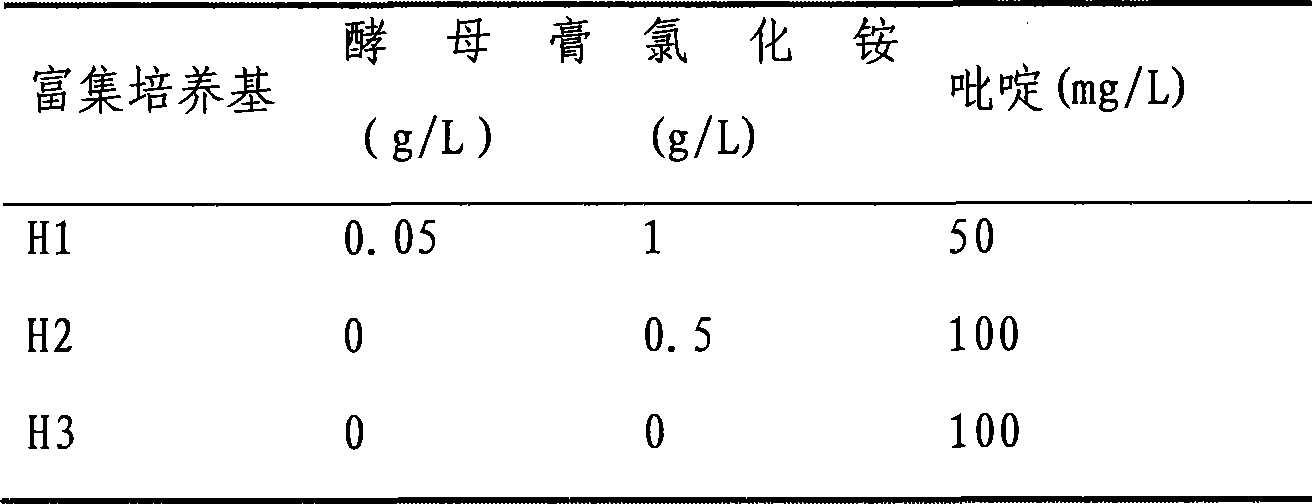

[0033] Screening of microbial flocculant-producing bacteria for oil refinery wastewater by pyridine screening

[0034] Take 2g of the sample and place it in a sterile mortar for grinding, then dilute it with sterile water to obtain a suitable concentration of bacterial suspension for later use. Use a 250mL Erlenmeyer flask to hold 60mL of enrichment medium H1, insert the numbered samples into it, and culture it on a shaker at 30°C and 140rpm for 48 hours, then transfer it to enrichment medium H2 with a 20% inoculum size, still 30 ℃, 140rpm shaker culture for 48 hours. Afterwards, 20% of the inoculum was added to the enrichment medium H3, and cultured on a shaker at 30° C. and 140 rpm for 48 hours. Dilute the enriched culture solution to obtain pure strains, and number them. Each single strain was inserted into the medium one by one, cultured with shaking at 28°C for 24 hours, and the culture solution was taken to measure its flocculation activity. (1) Determination method o...

Embodiment 2

[0051] Flocculation Test of Microbial Flocculants in Oil Refinery Wastewater Treatment

[0052] Thirteen strains with high flocculation rate were obtained from activated sludge by preliminary screening by pyridine screening method, and the flocculation experiment of refinery wastewater was further carried out. Add 300mL of oil refinery wastewater into a 500mL beaker, then add 50μL of microbial flocculant, and stir rapidly (200rpm) on a six-way mixer for 1min, so that the microbial flocculant and oil refinery wastewater are fully mixed to form fine alum flowers, and the wastewater is poured into the air pontoon. Use a small static air flotation device for air flotation. After standing for 5 minutes, take a 50mL water sample from the sampling port to measure the wastewater chemical oxygen demand (COD), petroleum and suspended solids, and calculate the removal rate of each indicator. The experimental results are shown in Table 6.

[0053] Table 6 The flocculation of oil refinery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com