Anticorrosion paint for decorating inner and external walls of power station transformer, and preparation thereof

A technology for transformers and inner and outer walls, applied in the direction of anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems affecting the dielectric loss of transformer oil, low anti-corrosion and decorative performance, and inability to adapt to new technical requirements, etc., to achieve Effects of prolonging service life and improving oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

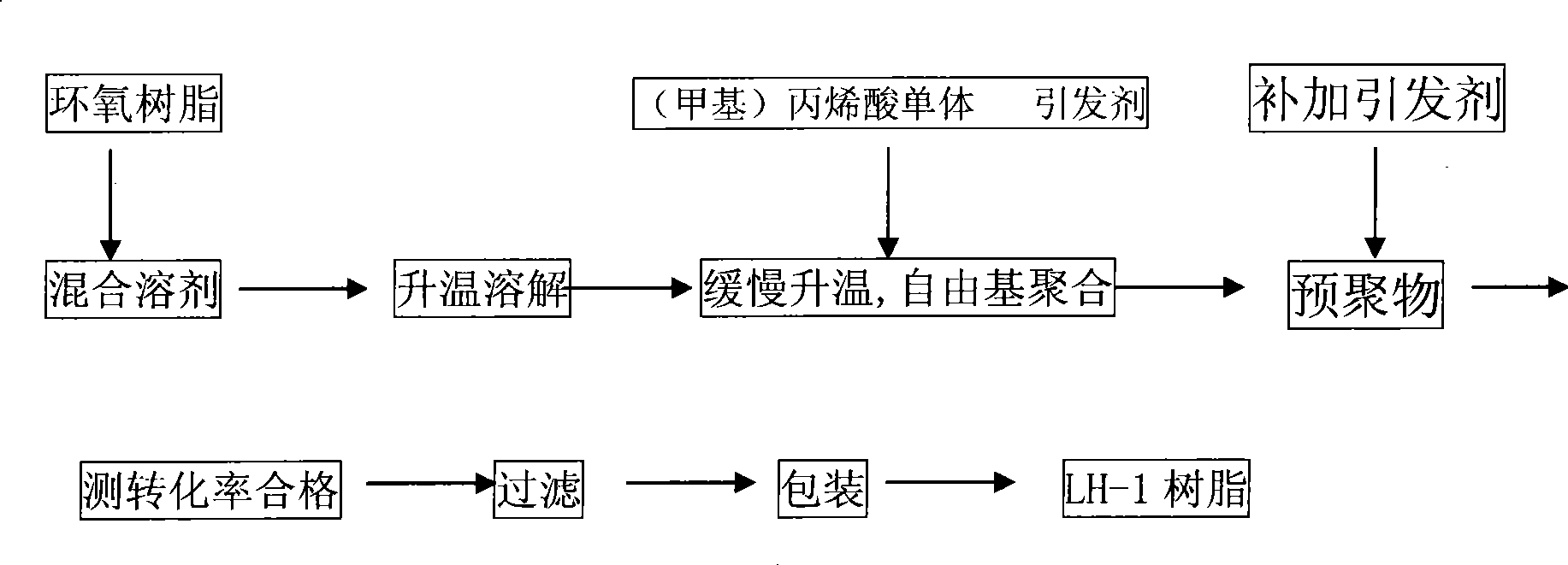

[0108] 1. LH-1 resin raw material

[0109] Methyl Methacrylate (MMA), Butyl Acrylate (BA), Hydroxypropyl Acrylate (HPA), Methacrylic Acid (AA), Benzoyl Peroxide (B, P, O), Tert-Butyl Hydroperoxide (DT), glycidyl tert-carbonate (ACE), epoxy resin (E-42, E-44), ethylene glycol ether acetate (CAC), butyl acetate (BAC), xylene (XYL) are all industrial products.

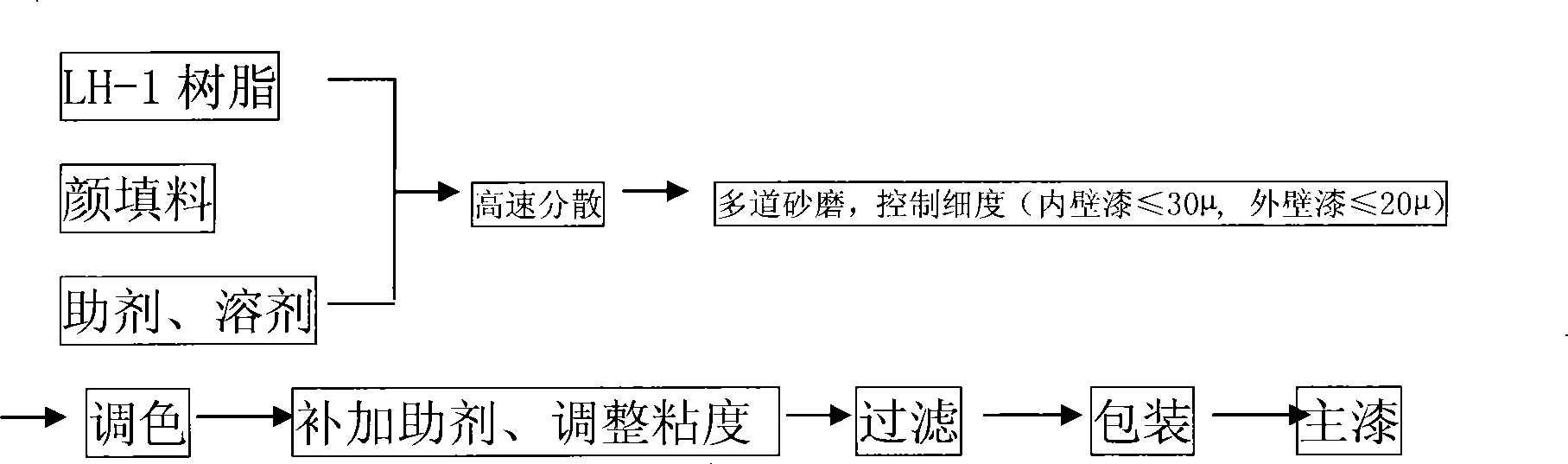

[0110] 2. The main raw materials for preparing the main paint

[0111] LH-1 resin (self-made), titanium dioxide (R, A type), carbon black (medium 3#), medium chrome yellow, phthalocyanine blue, modified aluminum tripolyphosphate, superfine filler, flake filler, various additives Agents and solvents are industrial products.

[0112] 3. The curing agent is IPDI trimer blended modified HDI biuret.

[0113] 4. Raw material component weight percentage of LH-1 resin

[0114] Raw material name Percentage

[0115] Glycidyl tertiary carbonate 10-15%

[0116] Methyl methacrylate 15-20%

[0117] Hydroxypropyl Acrylate 12-16%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com