Flexible coal powder foam concrete and preparation thereof

A technology of foam concrete and concrete, which is applied in the field of concrete, can solve the problems of poor coal seam quality, high plugging cost, mining interference, etc., achieve the effect of small impact, reduce transportation and construction costs, and improve efficiency and progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

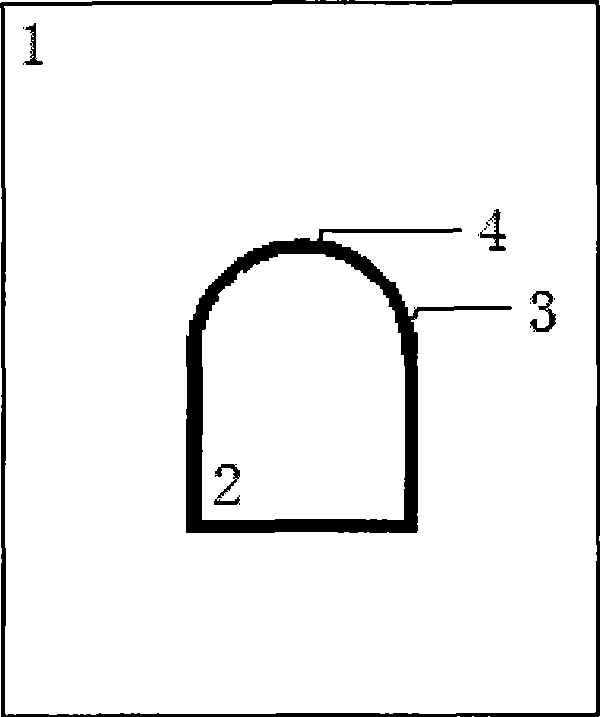

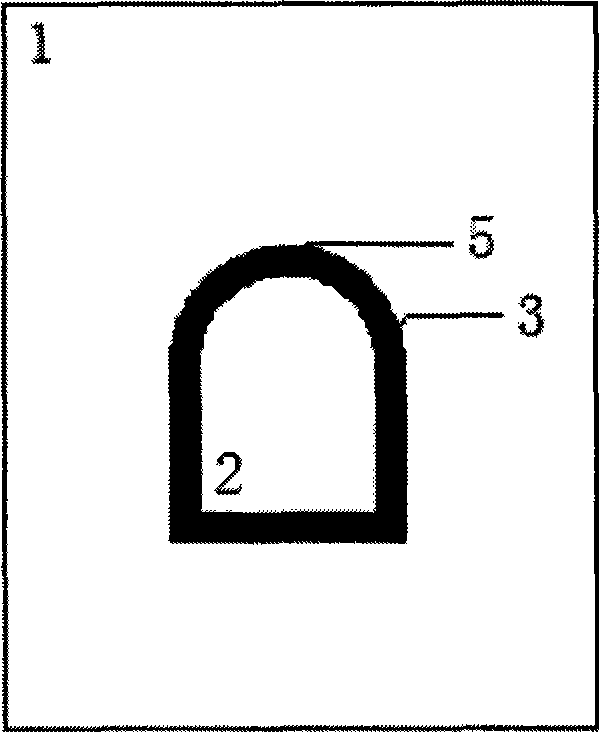

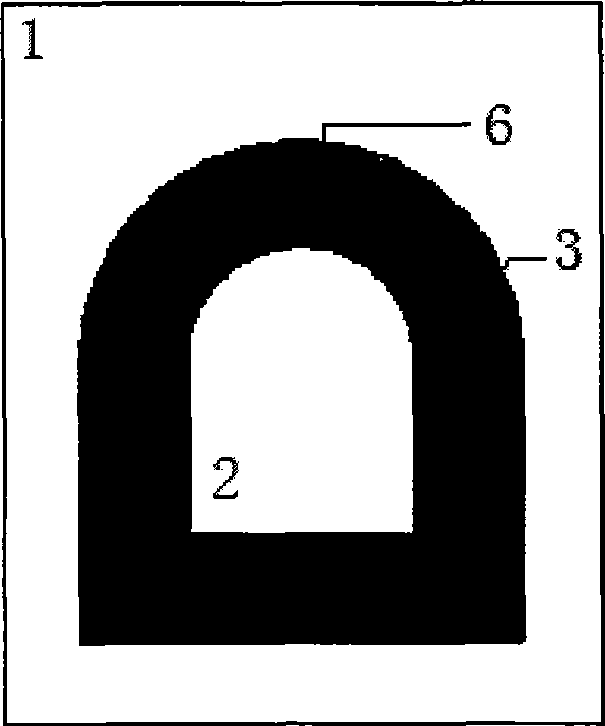

Image

Examples

Embodiment Construction

[0044] 1. Raw materials of this concrete

[0045] 1. Pulverized coal

[0046] The coal powder can be obtained locally, that is, the coal powder accumulated in the roadway is directly used in the underground drilling of the coal mine. It is composed of powders with different sizes and irregular shapes. The general diameter range is 10-1000μm, most of them are 20-50μm, and the bulk density is about 450-500kg / m 3 .

[0047] 2. Cement

[0048] Ordinary Portland cement (No. 32.5, No. 42.5, No. 52.5) is used for cement, and there are products on the market.

[0049] 3. Foaming agent

[0050] The foaming agent is the main admixture of this concrete. It is made by processing, deforming and synthesizing non-polluting animal protein oil and vegetable oil. It is neutral and has good affinity with water. It can be used in cement coal powder mixed slurry Generate independent and evenly distributed air bubbles, forming a large number of closed high-stability foam capsules, showing ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com