Stable lozenge compositions providing rapid release of nicotine

A composition, nicotine technology, applied in the directions of drug delivery, food science, medical preparations containing active ingredients, etc., can solve the problems of nicotine addiction, difficulty in quitting smoking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0129] Chewing gum compositions A, B, C and D for direct compression tablets containing 1.5 mg nicotine

[0130] Nicotine is absorbed on microcrystalline cellulose (MCC) as described in WO 2004 / 056363. Accordingly, in this example, 2.40ml of nicotine was dissolved in 25ml of ethanol (99.5%). 47.6g of PH-102 type MCC was loaded into a high speed mixer and the nicotine was added slowly. After the obtained wet material is vacuum dried, a fine-grained white powder of the nicotine-microcrystalline cellulose carrier complex is obtained. It is then mixed with the ingredients in the table below (except the magnesium stearate) in a suitable blender. Magnesium stearate was sieved and added and the resulting powder mixture was compressed into tablets using a tableting machine with 17 mm punches. A chewing gum having an average weight of 1.25 g was obtained.

[0131] Table 1: Rubber powders of compositions A, B, C and D

[0132] A B C D Element Concentration (%

...

Embodiment 2

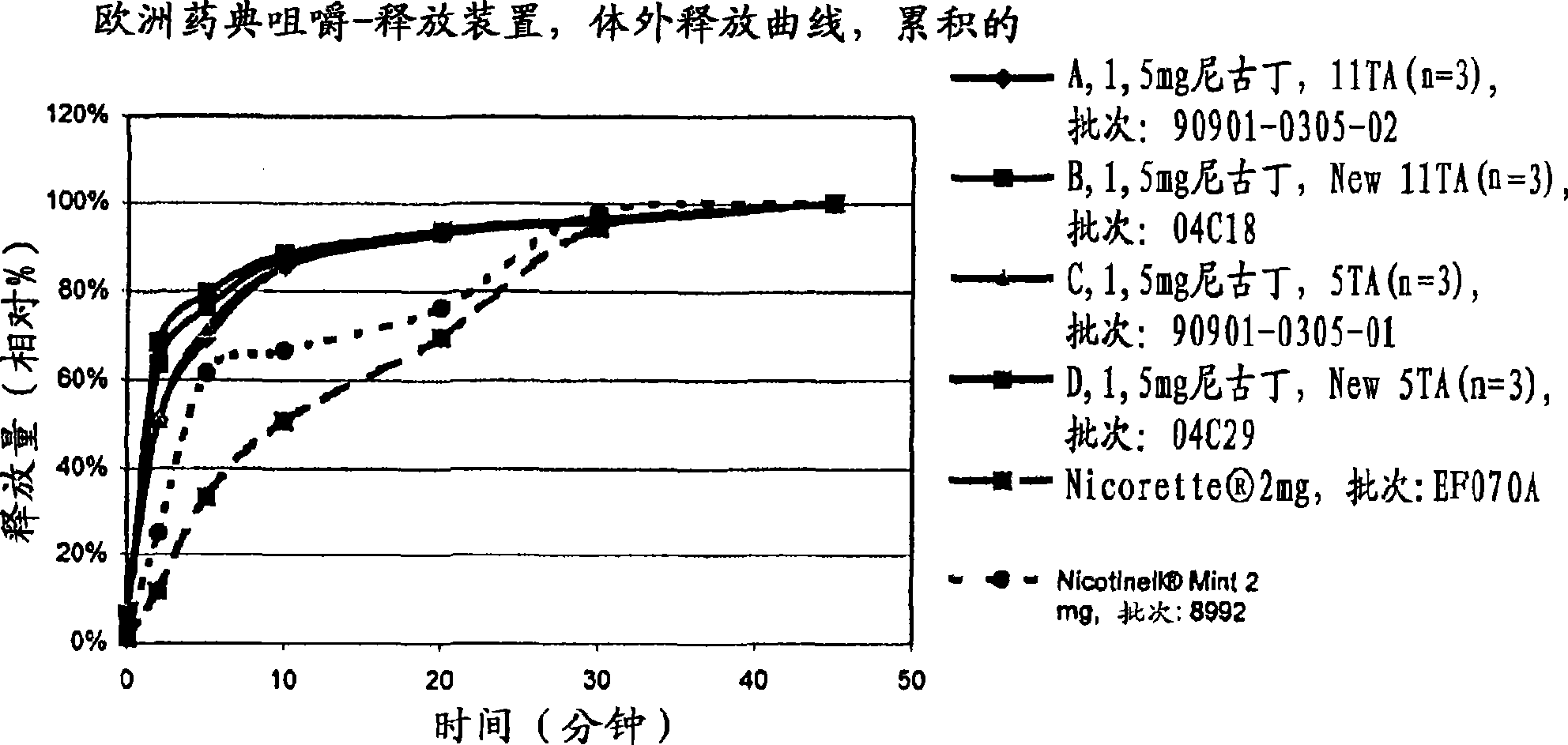

[0136] In vitro release of nicotine from direct compression chewing gum compositions

[0137] The in vitro release of compositions A, B, C and D prepared as described in Example 1 was tested and compared with a commercially available product all containing 2 mg nicotine and Compare in vitro release.

[0138] The in vitro dissolution test was carried out on the above-mentioned chewing gum, and the nicotine concentration in the solvent was determined by HPLC.

[0139] The results are shown in Table 4.

[0140] Furthermore, the in vitro release of nicotine from composition A is the same as that of formulation A and A comparison of the in vitro release of nicotine is shown below:

[0141] time,

[0142] In conclusion, this example shows that the direct compression chewing gum composition provides a very rapid initial release of nicotine in vitro. Furthermore, the initial release is faster compared to known compositions.

Embodiment 3

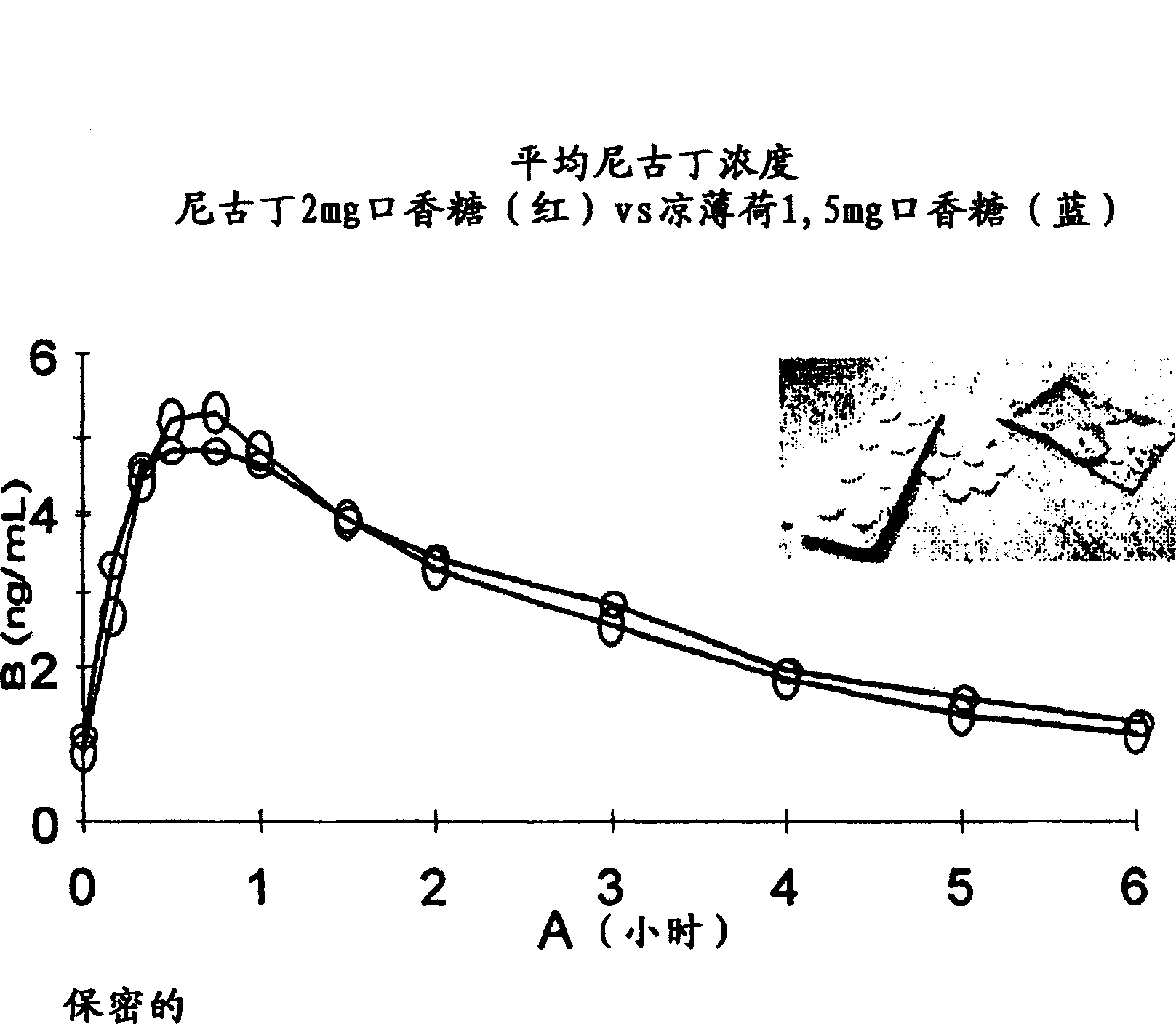

[0144] Buffer effect of nicotine uptake in vivo from DC

[0145] In vivo studies have shown that by adjusting the pH of saliva to a pH greater than 7, nicotine is absorbed more quickly from the oral cavity.

[0146] The effect of buffering agents in the in vivo uptake of nicotine was tested in a comparative study in which the following formulations were administered to individuals. Formulations 1, 2, 3 and 4 had substantially the same ingredients and the same amounts as Composition A in Example 1. In order to vary the amount of nicotine and contain buffer substances, the amount of isomalt is adjusted accordingly.

[0147] Formula 1: 4 mg nicotine, buffered (10 mg carbonate and 10 mg sodium bicarbonate).

[0148] Formula 2: 4mg nicotine, unbuffered.

[0149] Formulation 3: 2 mg nicotine, buffered (10 mg carbonate and 10 mg sodium bicarbonate).

[0150] Formula 4: 2mg nicotine, unbuffered.

[0151] contrast, including 2mg and 4mg chewing gum.

[0152] The results are sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com