Gallium nitride base LED chip and preparation method thereof

A light-emitting diode, gallium nitride-based technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of reducing the total reflection of the light-emitting diode chip, low luminous efficiency outside the light-emitting diode chip, and increasing the extraction of side light. Achieve the effects of increasing light extraction efficiency, improving external luminous efficiency, and reducing total reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

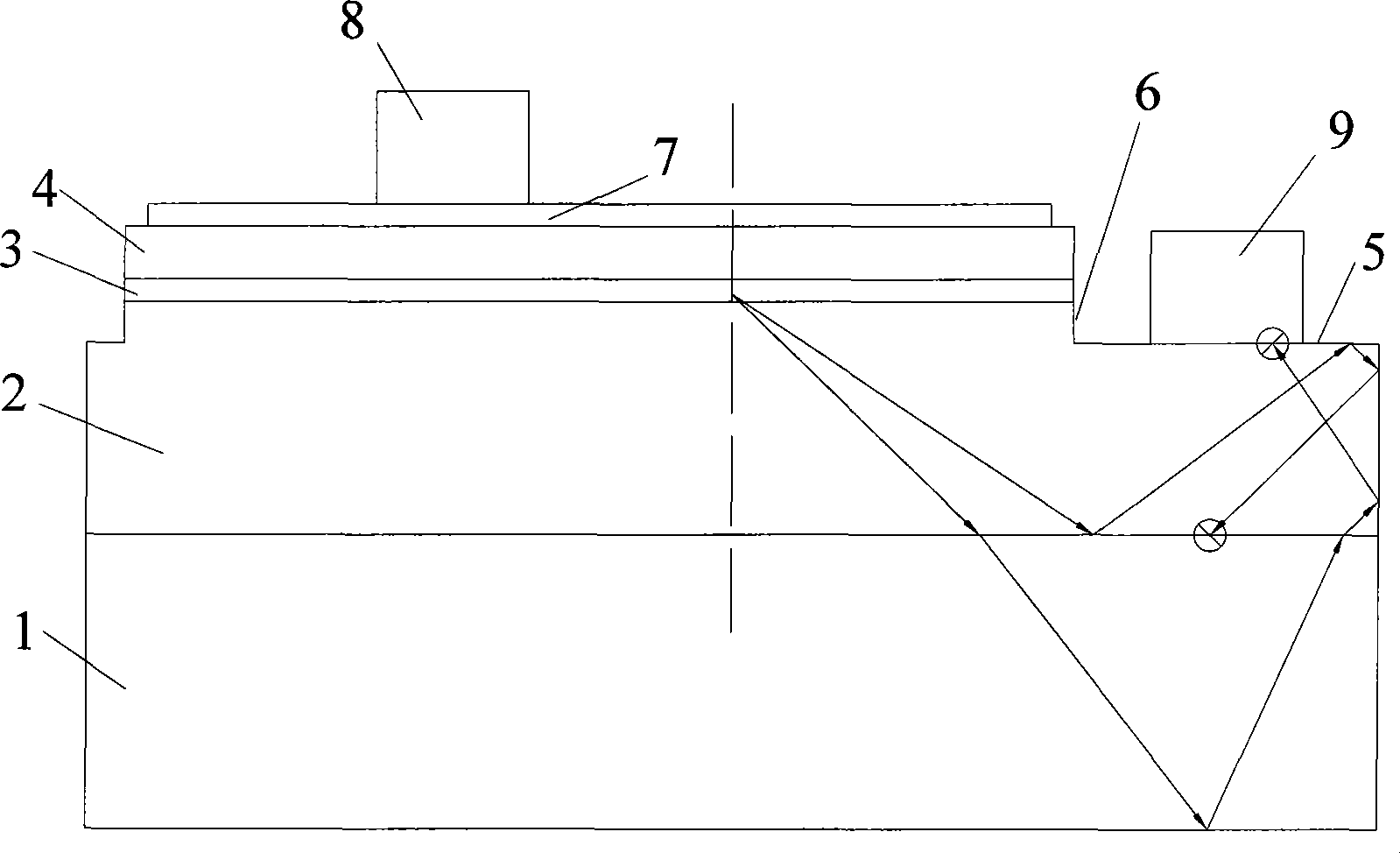

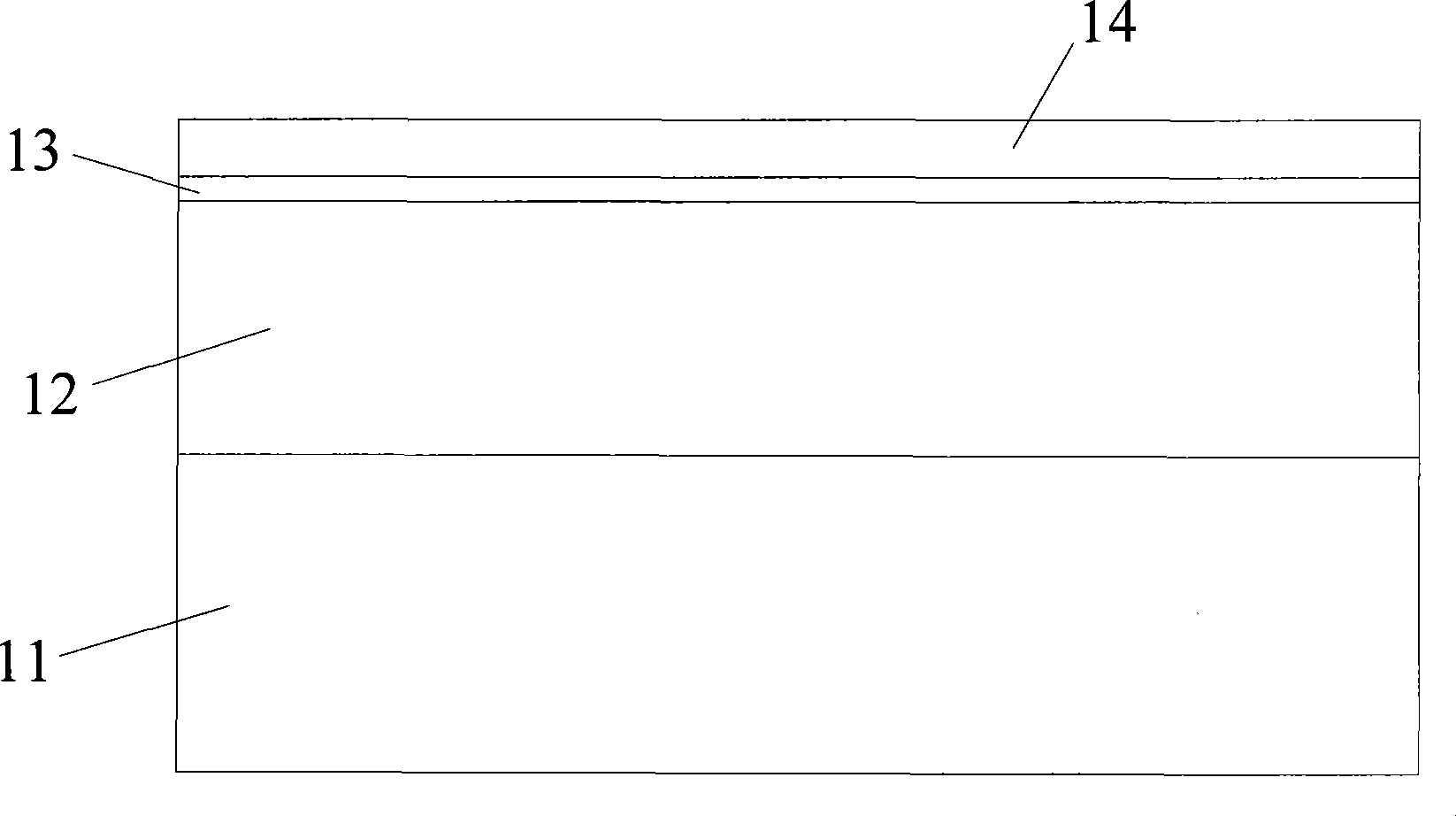

[0033] Provide a GaN-based light-emitting diode epitaxial wafer, such as figure 2 As shown, the structure of the epitaxial wafer includes a sapphire substrate II, an N-type GaN layer 12 , an active layer 13 , and a P-type GaN layer 14 . Besides sapphire, the material of the substrate can also be silicon carbide, zinc sulfide or gallium arsenide.

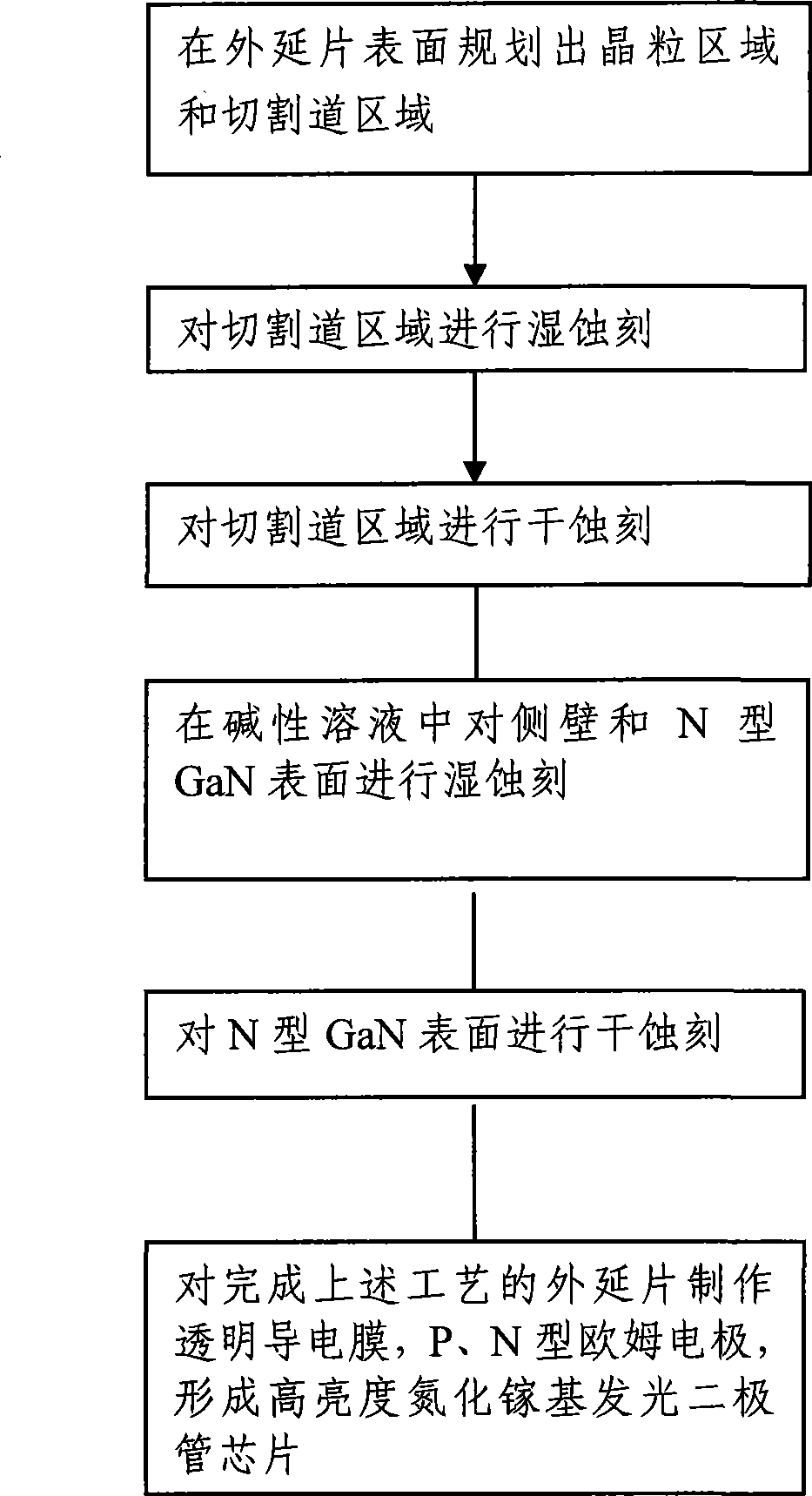

[0034] Please refer to image 3 , the manufacturing method of gallium nitride-based light-emitting diode chip described in the present invention, comprises the following steps:

[0035] (1) First generate a protective mask 15 on the surface of the epitaxial wafer, then coat photoresist, then use a photolithography mask to photoetch and develop on the photoresist surface, plan the pattern of the grain area and the pattern of the scribe line area 16 graphics,

[0036] (2) Carry out wet etching to the scribe line region 16, etch and remove the protection mask 15 of the scribe line region 16, finally remove the undeveloped photoresis...

Embodiment 2

[0042] The manufacturing method of the gallium nitride-based light-emitting diode chip according to the present invention comprises the following steps:

[0043] (1) First generate a protective mask 15 on the surface of the epitaxial wafer, then coat photoresist, then use a photolithography mask to photoetch and develop on the photoresist surface, plan the pattern of the grain area and the pattern of the scribe line area 16 graphics,

[0044](2) Carry out wet etching to the scribe line area 16, etch and remove the protective mask 15 of the scribe line area 16, finally remove the undeveloped photoresist, and expose the protective mask 15 on the grain area surface,

[0045] (3) Under a pressure environment of 10 millitorr, use a plasma etching machine to dry-etch the scribe line region 16 mainly by chemical etching, expose the N-type GaN layer 12 and form sidewalls, and the N-type GaN layer 12 after dry etching The distance between the surface 18 of the type GaN and the surface...

Embodiment 3

[0050] The manufacturing method of the gallium nitride-based light-emitting diode chip according to the present invention comprises the following steps:

[0051] (1) First generate a protective mask 15 on the surface of the epitaxial wafer, then coat photoresist, then use a photolithography mask to photoetch and develop on the photoresist surface, plan the pattern of the grain area and the pattern of the scribe line area 16 graphics,

[0052] (2) Carry out wet etching to the scribe line area 16, etch and remove the protective mask 15 of the scribe line area 16, finally remove the undeveloped photoresist, and expose the protective mask 15 on the grain area surface,

[0053] (3) Under the pressure environment of 7 mTorr, use the plasma etching machine to dry-etch the scribe line region 16 mainly by chemical etching, expose the N-type GaN layer 12 and form sidewalls, and the N-type GaN layer 12 after dry etching The distance between the GaN surface 18 and the surface of the sapp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com