Steel plastic integral composite energy-saving environment protection window and manufacturing method thereof

It is an energy-saving and environmentally-friendly overall technology, which is applied in the direction of windows/doors, building structures, wing leaf frames, etc. It can solve the problems of poor air tightness of windows, large energy waste, poor heat insulation, etc., and achieve the effect of overcoming poor air tightness of windows

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing.

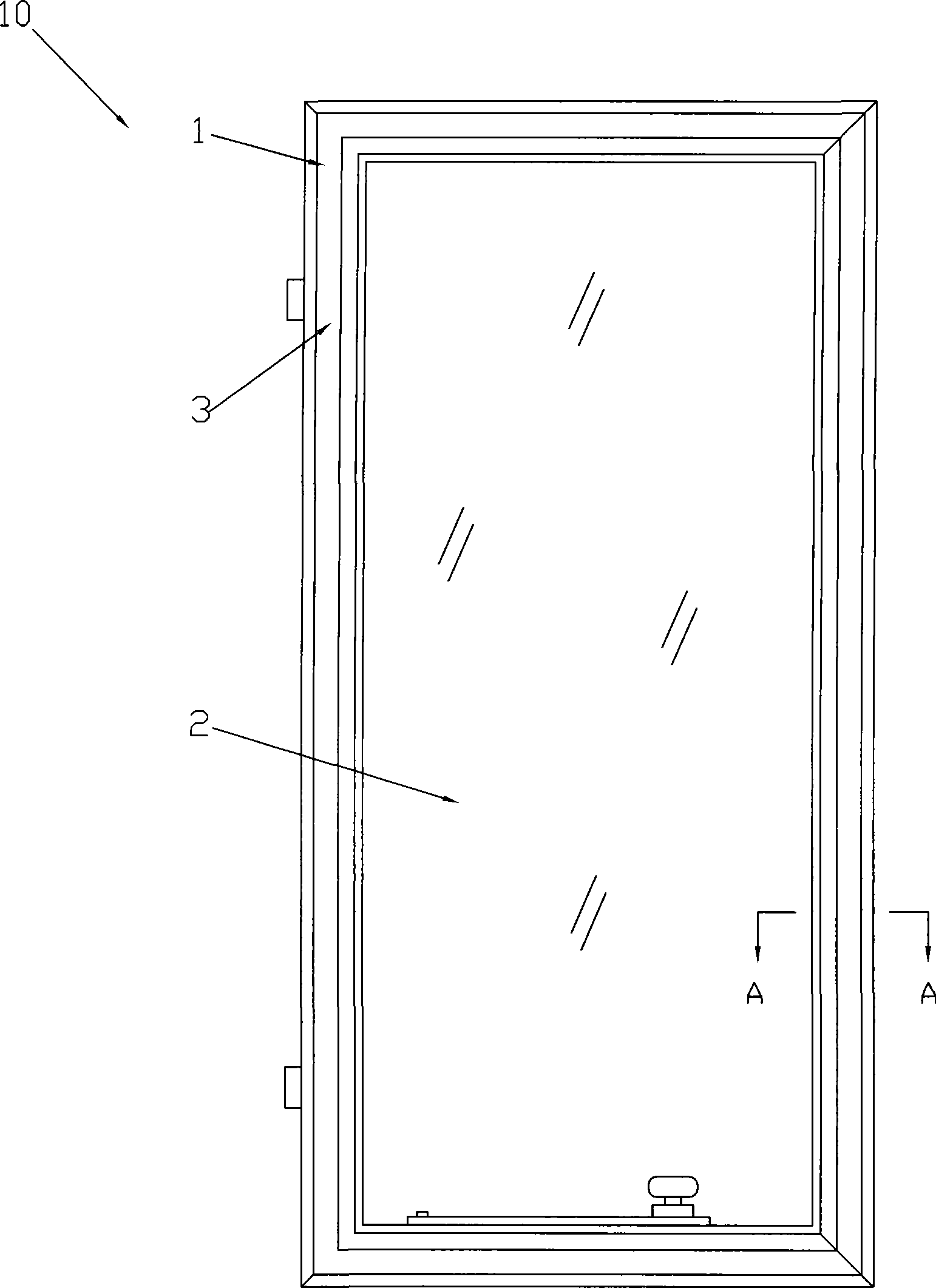

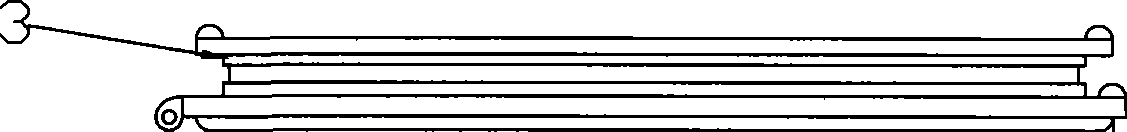

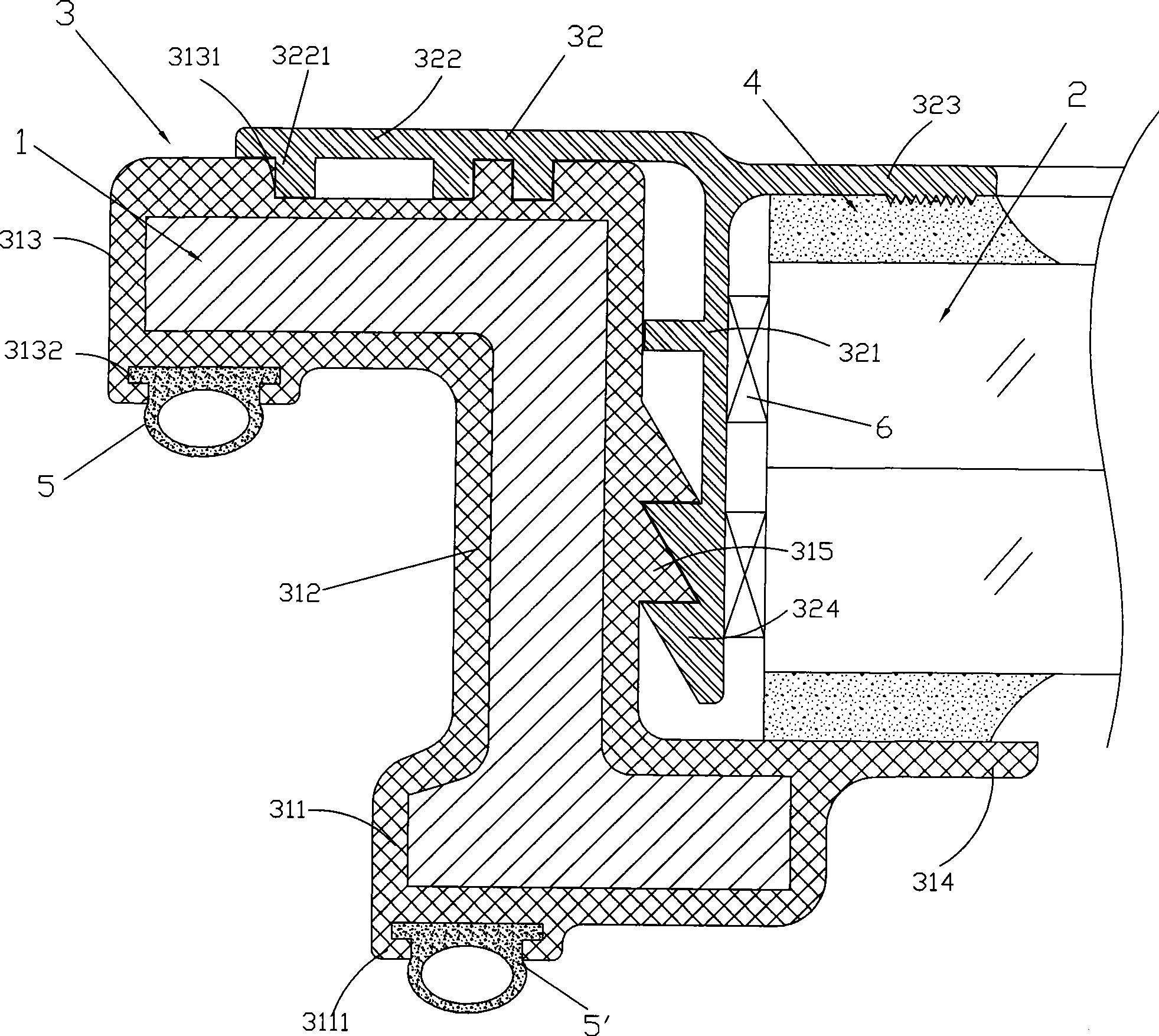

[0034] see Figure 1 ~ Figure 3 , the energy-saving and environment-friendly window of the present invention includes a window sash 10 and a window frame 20; wherein, the window sash 10 includes a metal frame 1 and a glass 2; it also includes a sash frame profile 3, which is coated on the outside of the metal frame 1, and the glass 2 is fixed inside the frame; The sash frame profile 3 is made of plastic.

[0035] The sash frame profile 3 includes a base 31 with a Z-shaped cross section and a hollow cavity 30 for setting a metal frame; the base 31 includes a lower fixing part 311 bent upward from one side of the lower fixing part 311 The extended connecting portion 312 and the upper fixing portion 313 formed by bending and extending from the connecting portion 312; the outer end of the lower fixing portion 311 extends outwards to a first support portion 314 for fixing the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com