FRP insulating sleeve for wind power generator and forming method thereof

A technology for wind turbines and insulating sleeves, applied in insulators, insulators, circuits, etc., can solve the problems of high cost of bonding tooling, low motor load, small cooling capacity, etc. Tightness and insulation properties, the effect of overcoming low external pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

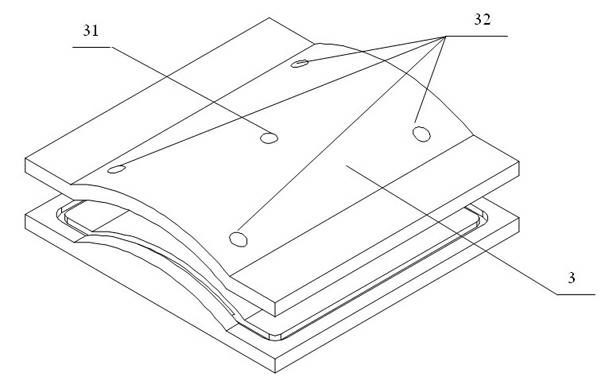

[0024] The RTM molding process refers to the traditional resin transfer molding process of composite materials. This process injects the prepared resin glue into the mold cavity for product molding by injection. Under the action of pressure, the resin glue is injected into the reinforced material It flows in the preform and transfers to various parts, fills the mold cavity and clears the air bubbles in the mold cavity through flow glue, and then solidifies to form a molding process of composite material products.

[0025] The fiberglass insulating sleeve of the present invention will be further described in detail with reference to the accompanying drawings.

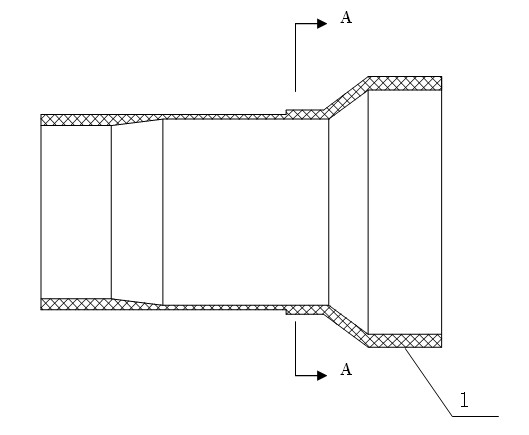

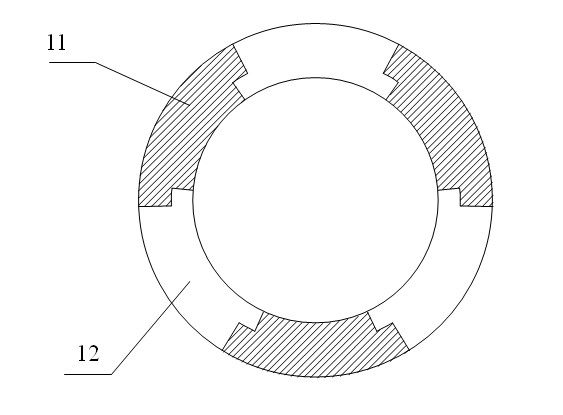

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the FRP insulating sleeve 1 of the present invention is composed of concentric and equal arc-shaped multi-lobed arc-shaped cylinder walls assembled and bonded to the inner surface of the wind turbine stator.

[0027] The optimal setting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com