Conductive polymer resin and core-sheath composite structure dyeable antistatic fiber

A conductive polymer, antistatic fiber technology, applied in conductive/antistatic filament manufacturing, fiber processing, conjugated synthetic polymer rayon, etc., can solve the problem of antistatic fiber antistatic performance not durable, spinning difficulty Large and other problems, to achieve the effect of good antistatic effect, easy dyeing, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

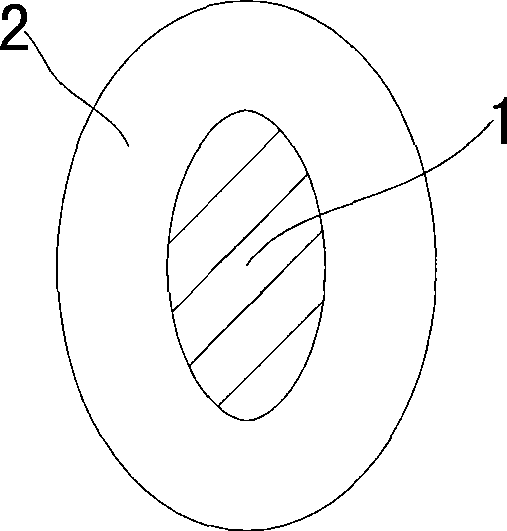

[0039] Example 1: A conductive polymer resin and a skin-core composite structure dyeable antistatic fiber made from the resin

[0040] A conductive polymer resin, consisting of the following raw materials in mass percentage:

[0041] Polyetheresteramide 15%;

[0042] Base resin 76%;

[0043] Salt 2%;

[0044] UV absorber Chlorobenzotriazole (UV-326) 3%;

[0045] Calcium zinc composite heat stabilizer 4%.

[0046] Base resin selects polybutylene terephthalate (PBT), its viscosity VI value is 0.8, salt selects bis(trifluoromethylsulfonyl)imide lithium, bis(trifluoromethylsulfonyl)imide Lithium imide (Li(CF 3 SO 2 ) 2 N) dissolved in polyether ester amide to form a coordination complex.

[0047] The skin layer and the core layer were prepared into four kinds of skin-core composite structure dyeable antistatic fibers according to the following mass percentage ratios:

[0048] Select 20%, 30%, 40% and 50% of the cortex respectively;

[0049] The core layer corresponds to ...

Embodiment 2

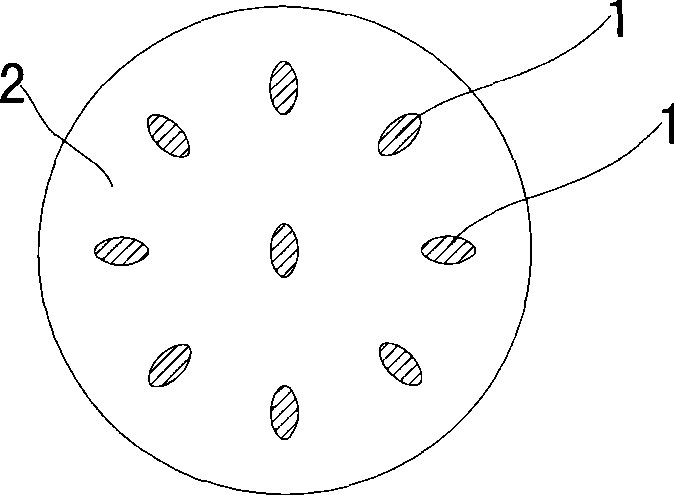

[0059] Embodiment 2: A conductive polymer resin and a skin-core composite structure dyeable antistatic fiber made of the resin

[0060] A conductive polymer resin, consisting of the following raw materials in mass percentage:

[0061] Polyetheresteramide 57%;

[0062] Base resin 36%;

[0063] Salt 3%;

[0065] The base resin is polybutylene terephthalate (PBT), its viscosity VI value is 0.8, and the salt is calcium trifluoromethanesulfonate (Ca(CF 3 SO 3 ) 2 ) and zinc perchlorate (Zn(ClO 4 ) 2 ), the mass ratio between the two is 1:1, calcium trifluoromethanesulfonate (Ca(CF 3 SO 3 ) 2 ) and zinc perchlorate (Zn(ClO 4 ) 2 ) dissolved in polyether ester amide to form a coordination complex.

[0066] The skin layer and the core layer were prepared into four kinds of skin-core composite structure dyeable antistatic fibers according to the following mass percentage ratios:

[0067] Select 20%, 30%, 40% and 50% of the cortex respectively;

...

Embodiment 3

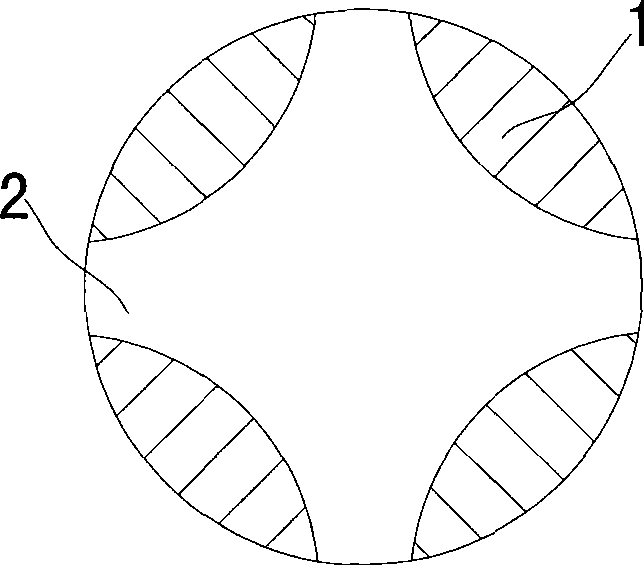

[0074] Example 3: A conductive polymer resin and a skin-core composite structure dyeable antistatic fiber made from the resin

[0075] A conductive polymer resin, consisting of the following raw materials in mass percentage:

[0076] Polyetheresteramide 55%;

[0077] Base resin 44%;

[0078] Salt 1%;

[0079] The base resin is polyamide (PA6) and polypropylene (PP), the mass ratio between the two is 2:1, the viscosity VI value is 0.8, and the salt is lithium perchlorate (LiClO 4 ), lithium trifluoromethanesulfonate (LiCF 3 SO 3 ), lithium tetrafluoroborate (LiBF 4 ), lithium bis(trifluoromethylsulfonyl)imide (Na(CF 3 SO 2 ) 2 N), 1,1,1-trifluoro-C-[(trifluoromethyl)sulfonyl)methanesulfonamide] sodium salt (Na(CF 3 SO 2 ) 2 C), sodium perchlorate (NaClO 4 ), the mass ratio between the six is 1:1:2:1.5:3:0.5, and the salt mixture is dissolved in polyether ester amide to form a coordination complex.

[0080] The skin layer and the core layer were prepared into four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com