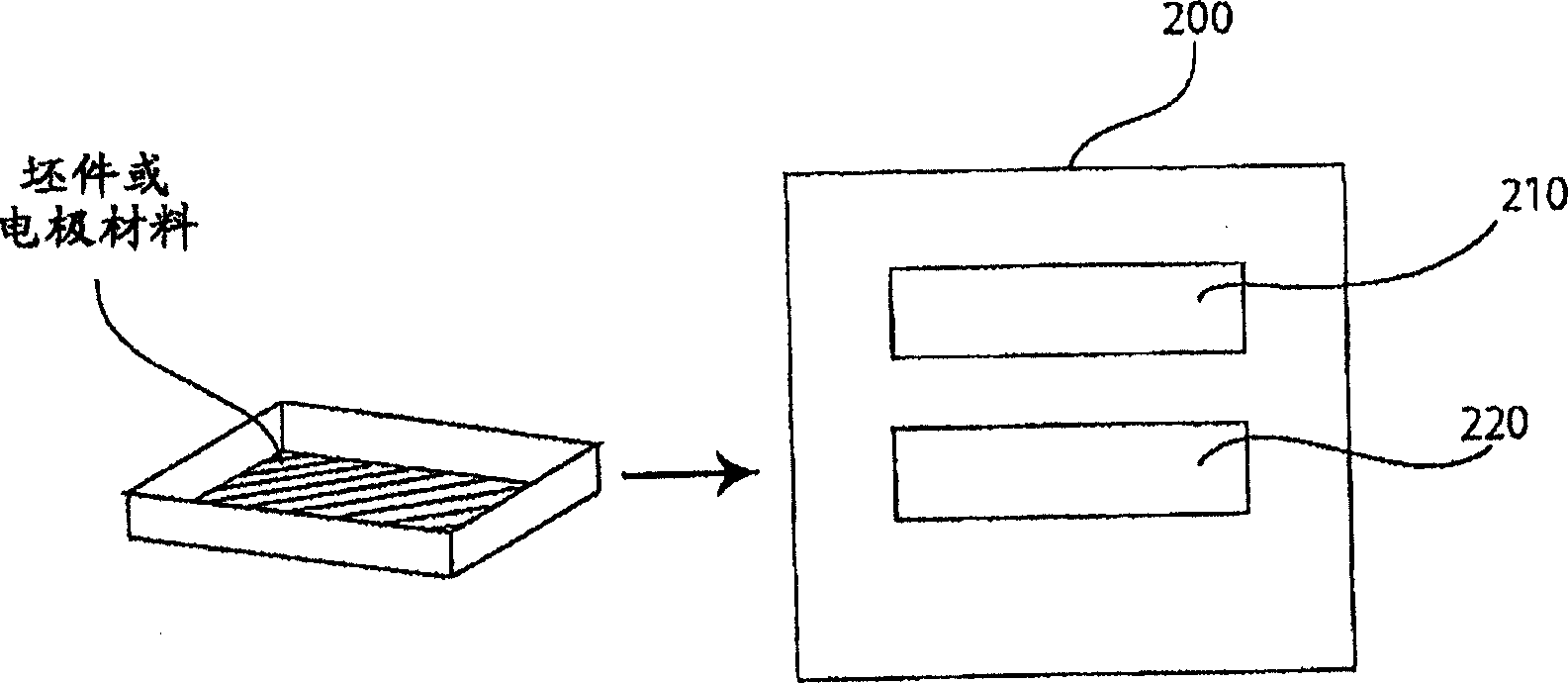

Electrode for use in a deionization apparatus and method of making same

A technology for preparing electrodes and conductive carbon, applied in chemical instruments and methods, electrolytic coatings, coatings, etc., can solve problems affecting absorption and electrical properties, and achieve the effect of uniform resistance and power distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

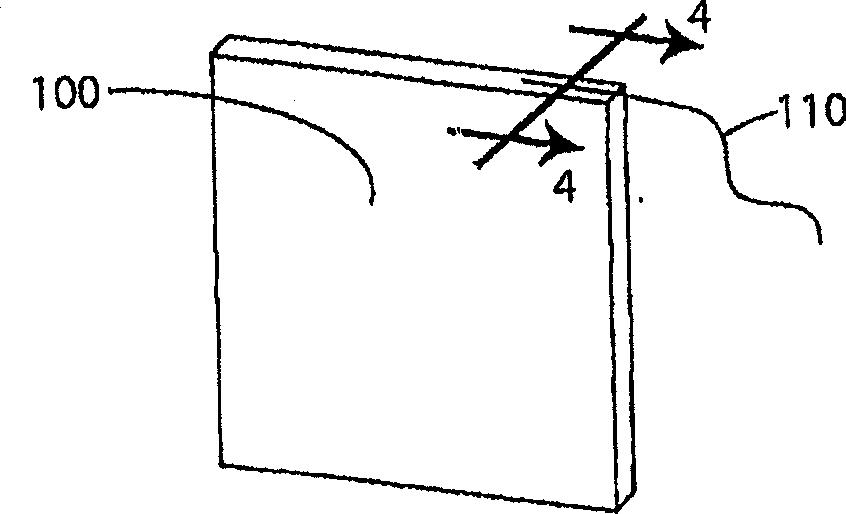

Method used

Image

Examples

Embodiment

[0116] Electrodes manufactured according to the above principles, their properties / characteristics were measured and listed in the table below:

[0117] area

[0118] nature Measurements BET surface area 481.41m 2 / g Langmuir surface area 541.89m 2 / g Single point surface area at P / Po 0.1027 478.483m 2 / g Diameters from 17.0000 to 3000.0000A

Cumulative adsorption of BJH in the pores between

surface area 21.6927m 2 / g

Pore area 419.5970m 2 / g

[0119] volume

[0120] nature Measurements At P / Po 0.9756 diameter less than

812.7211A Porosity single-point total hole

void volume 0.198113

Diameters from 17.0000 to 3000.0000A

Cumulative adsorption of BJH in the pores between

Pore volume 0.032289cc / g

Pore volume 0.166676cc / g

[0121] Pore size

[0122] nature Measurements Langmuir average pore diameter (4V / A) 14.6238A BJH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com