Double-layer composite hot melt adhesive film for bonding metal and plastic

A technology of hot-melt adhesive film and double-layer compounding, which is applied in the direction of film/flaky adhesives and adhesives, etc. It can solve the problems of volatile substances in liquid adhesives, inconvenient processing and operation, and hazards to operators, so as to achieve the goal of processing The operation is convenient and fast, the operation is simple and convenient, and the effect of reducing the difficulty of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

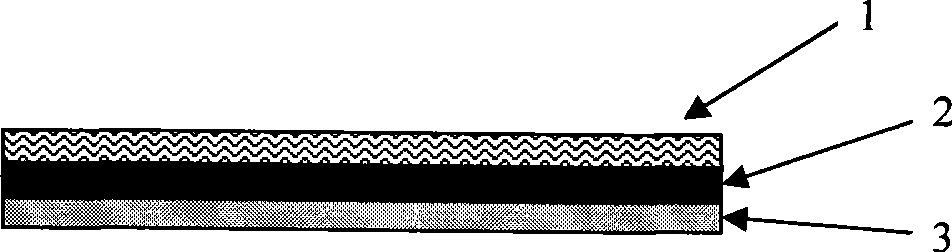

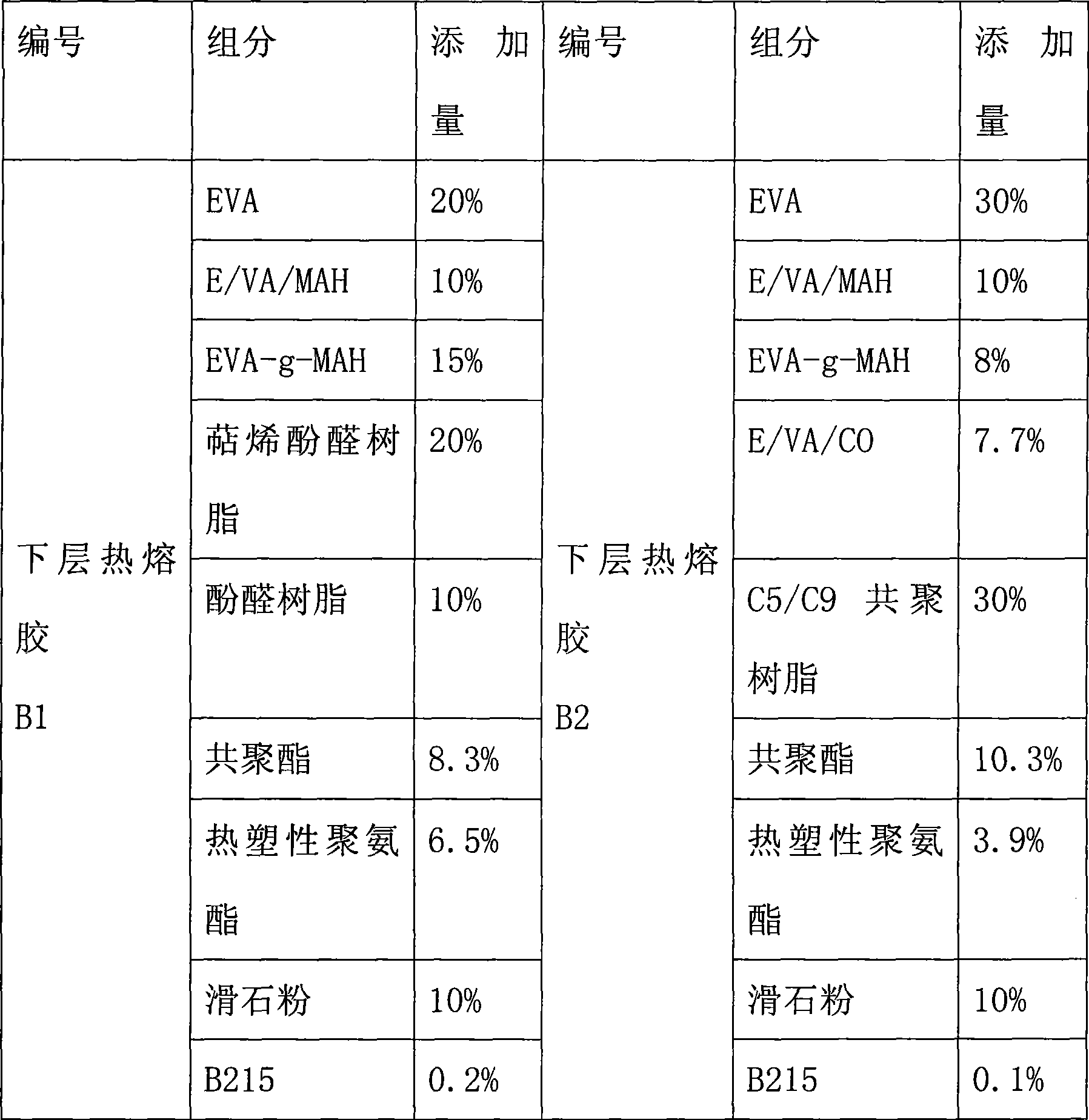

[0017] As shown in Figure 1: the present invention is composed of upper and lower double-layer adhesive films. The thickness of the double-layer composite adhesive film is 0.05 mm to 0.20 mm, wherein the lower layer is attached with release paper 3, and the upper layer is a hot-melt adhesive bonded with metal. Adhesive layer 1, the thickness of which is 20-60% of the thickness of the composite film, the lower layer is a hot-melt adhesive layer 2 bonded with plastic, whose thickness is 40-80% of the thickness of the composite film, the lower layer is attached with glassine release paper, Composite by co-extrusion casting or double-layer composite hot melt adhesive film.

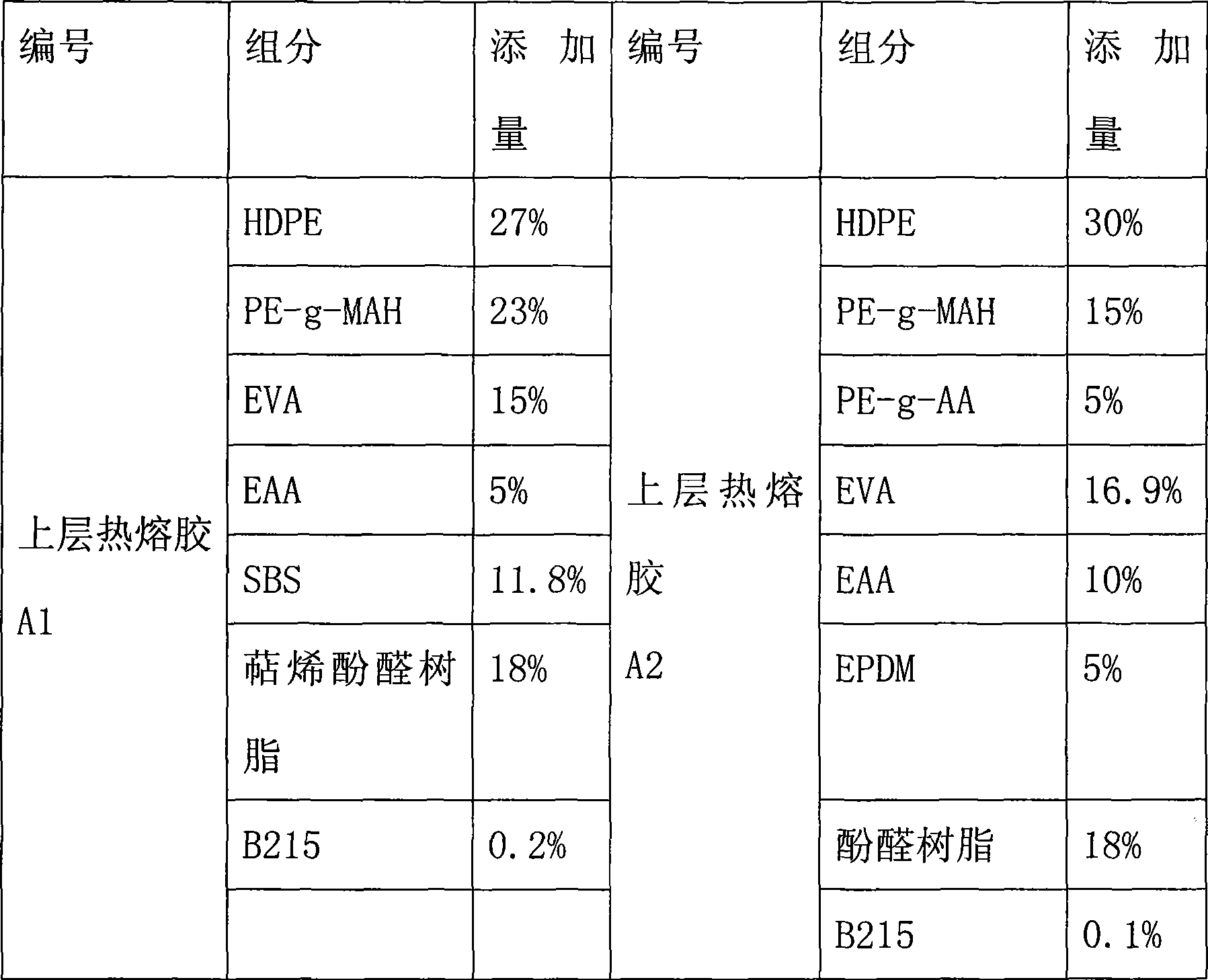

[0018] The hot melt adhesive on the upper layer is composed of 10-50% polyethylene by weight, 5-30% polyethylene graft polymer, 10-40% ethylene copolymer, 5-30% thermoplastic elastomer, 10-30% polyethylene 50% of tackifier and 0.1-1.0% of antioxidant and ultraviolet absorber are extruded and granulated by a tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com