Oxygen sensor ceramic induction feeler forming device and molding and manufacturing method

A technology of oxygen sensor and manufacturing method, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of high processing cost, low yield rate, low production efficiency, etc., and achieve the effect of simplified and stable process flow and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to illustrate the idea and purpose of the present invention, the present invention will be further described below with reference to the drawings and specific embodiments.

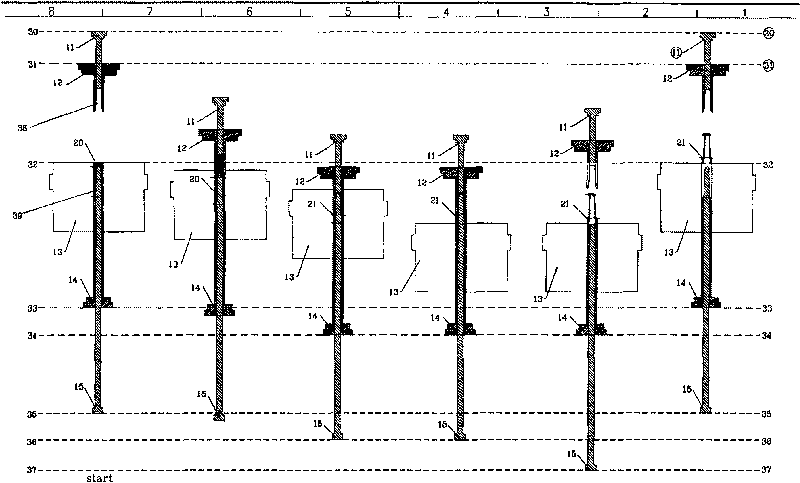

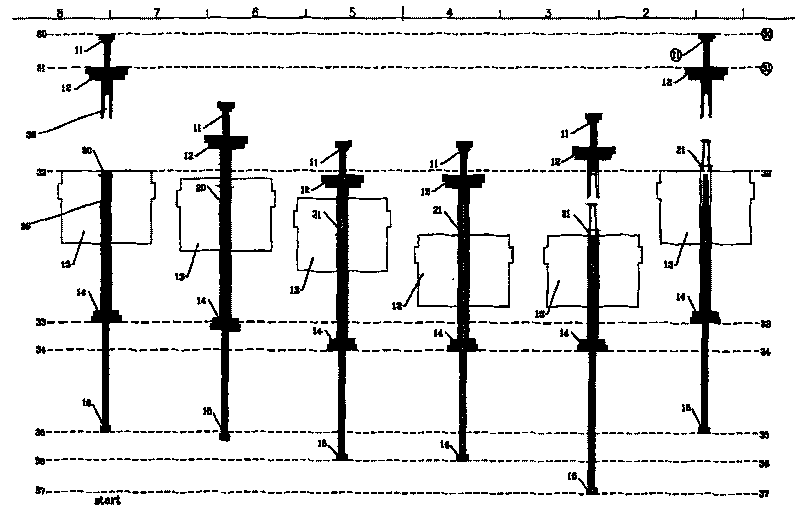

[0022] Such as figure 1 As shown, the present invention provides a molding device used in the molding process of a ceramic induction probe, which mainly includes a female mold 13, an upper module 11, an upper second module 12, a next module 14 and a lower second module 15. The female mold 13 is provided with a mold cavity 20. The above-mentioned components are located in the same group of mold bases in the vertical direction. The upper module 11 and the upper second module 12 are located above the female mold 13, and the next module 14 and the lower second module 15 are located in the female mold. Under the mold 13, the movable sleeve of the upper module 11 is placed in the upper second module 12, and a groove 38 is formed between the two; the movable sleeve of the lower second module 15 is pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com