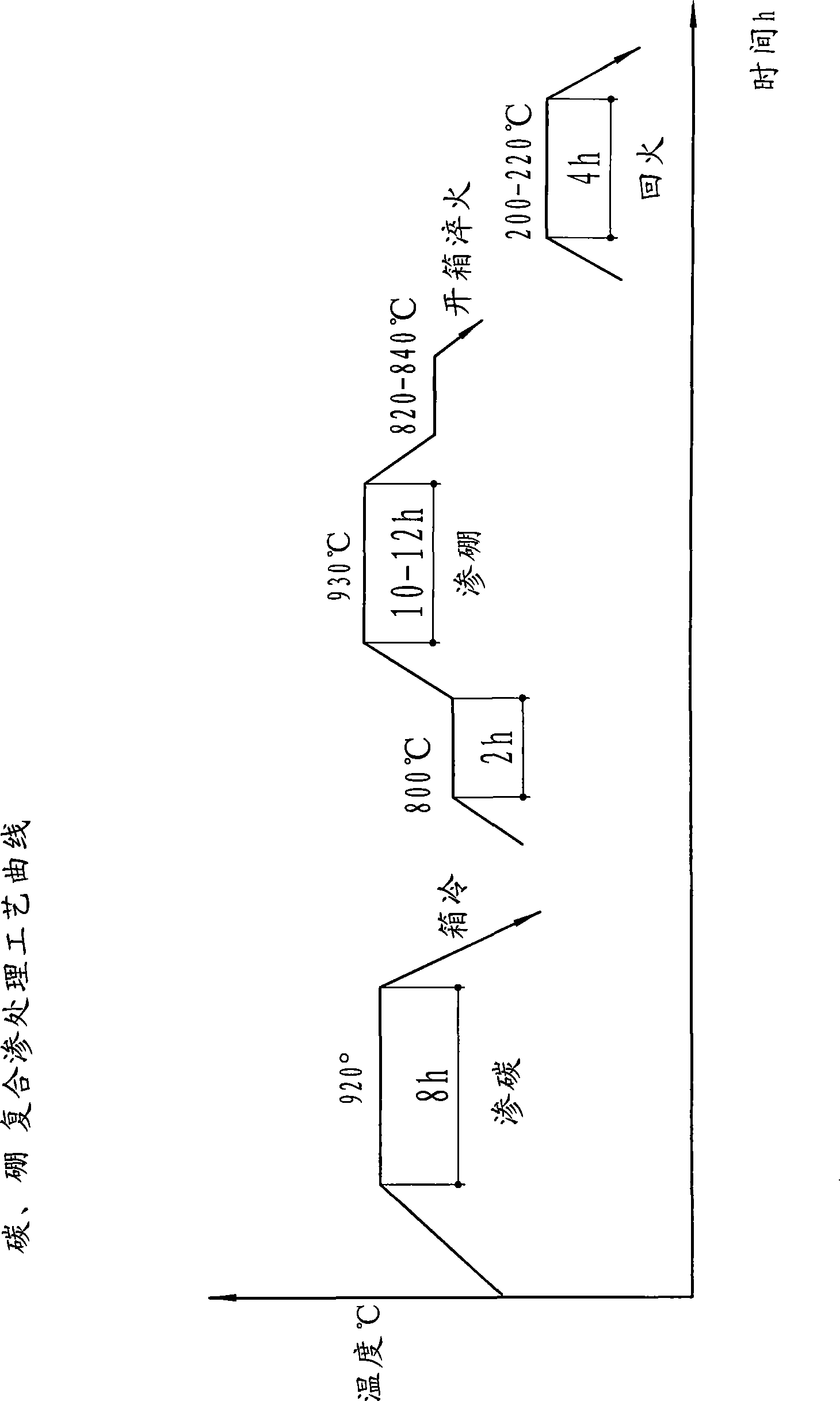

Carbon and boron complex seeping treatment process of Mg-Cr refractory product mould

A technology of refractory products and processing technology, applied in the direction of metal material coating technology, coating, solid diffusion coating, etc., to achieve the effect of improving wear resistance and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described in detail below: 1, mold is carried out carburizing treatment, and its heating temperature is 920 ℃, and heat preservation 8 hours, box cooling then, does not quench; Make steel surface have 1.0 carbon concentration, carburizing layer depth is 1.5mm, carburizing The layer is cooled in the infiltration agent to prevent oxidation. 2. Carry out boronizing treatment on the mold again. Before packing the mold, grind and polish the sundries and oxides on the surface of the mold, and wipe and dry them with alcohol; Made of heat-resistant steel), the mold is spaced at a gap of 20mm in the box, and the boronizing agent is placed in the gap to fill it, cover the box cover and seal it with refractory soil; put it in a box-type electric furnace for boronizing treatment.

[0013] The boronizing agent used in this invention adopts 7% of boron donor, 10% of infiltration agent, and the rest is filler.

[0014] The boron supplying agent adopts industr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com