Treatment method of metal printing plate surface for offset-printing plate-making

A processing method and printing plate technology, applied in the field of printing plates, can solve problems such as environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

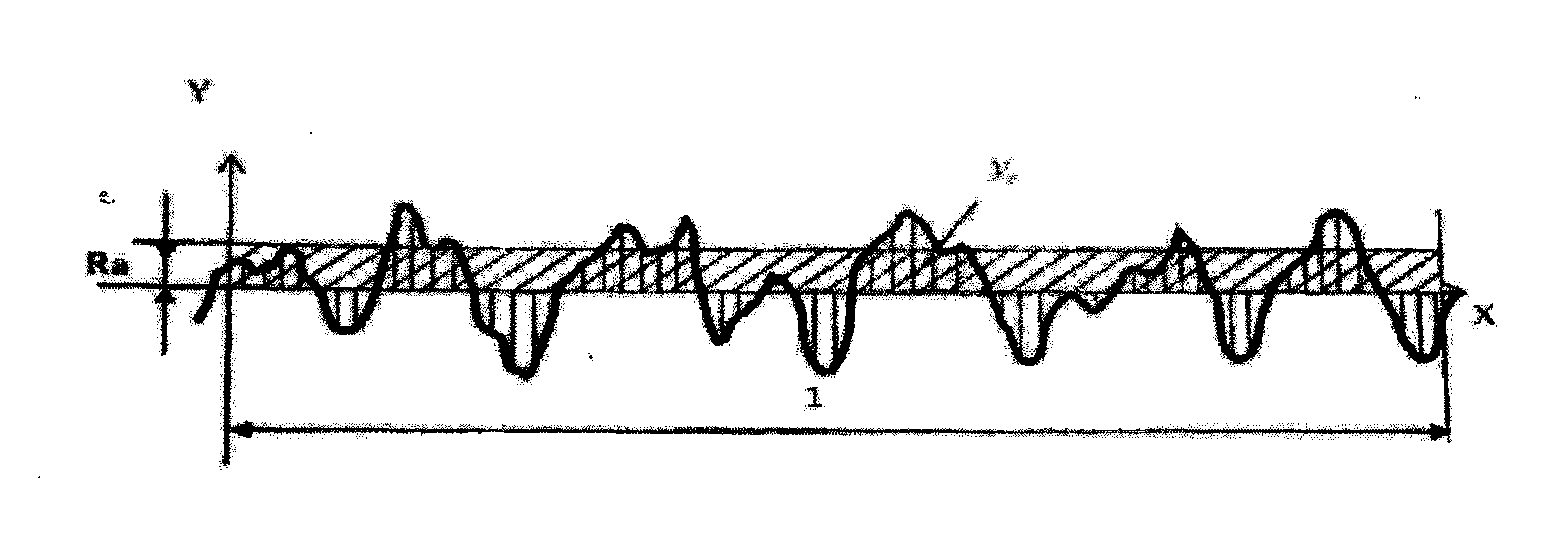

[0034] Use 200# (particle size: 83.0 μm) sandpaper to polish the surface of the aluminum plate base at a pressure of 0.5KPa. After sanding, apply hydrophilic polymer paint. Weigh 0.75g of gelatin and 0.25g of silicon dioxide (with a particle size of 2-3μm), put them into a 100ml Erlenmeyer flask, add 49g of distilled water, and stir for 6-10 hours to fully dissolve them. Cut the aluminum plate into 10×10cm 2 , washed with acetone and distilled water successively, and dried. On the glue leveler, the coating composition is coated on the aluminum plate by the spin coating method, and the coating amount is 1g / m by controlling the speed of the glue leveler 2 . Bake at 200°C for about 1 hour, and measure the contact angle, Ra value and adhesion of the plate, see Tables 1, 2 and 3.

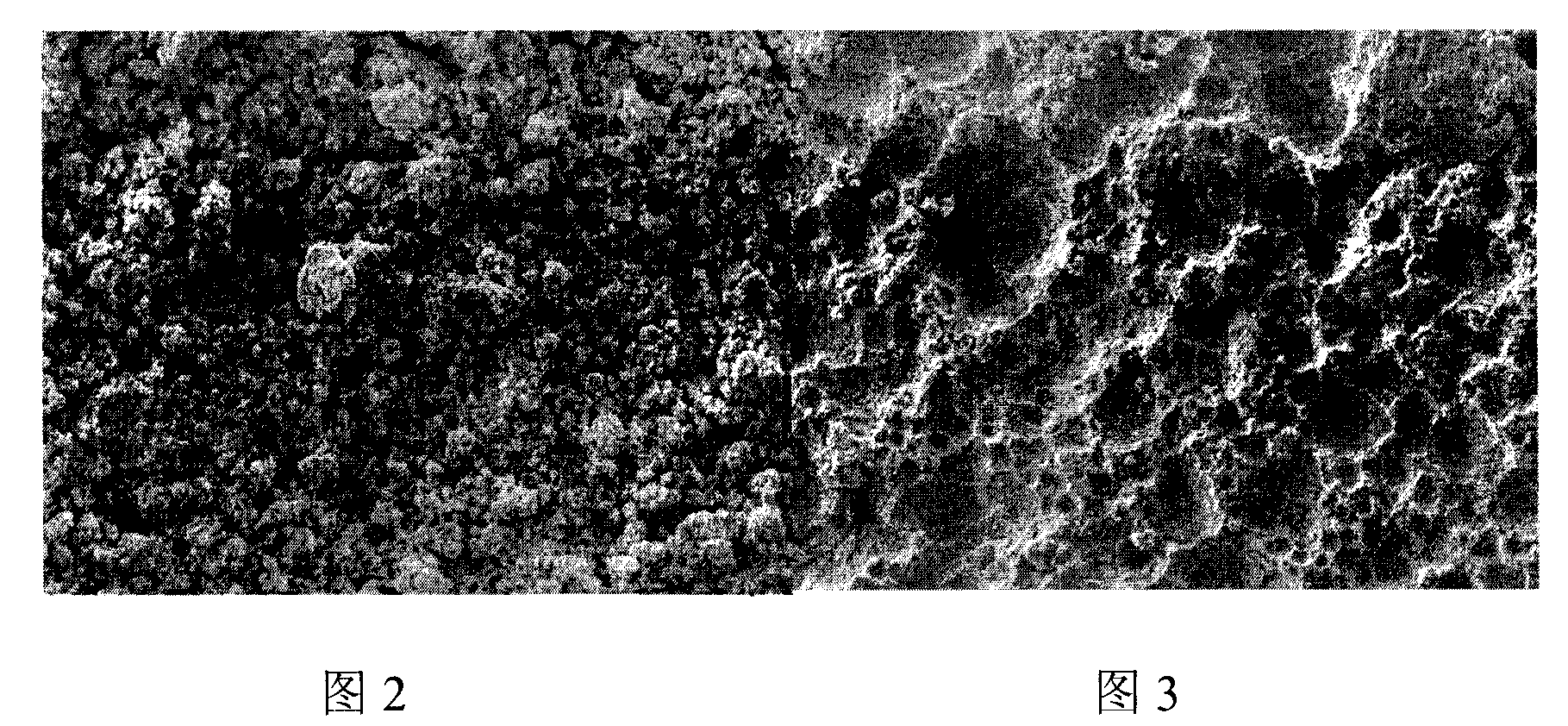

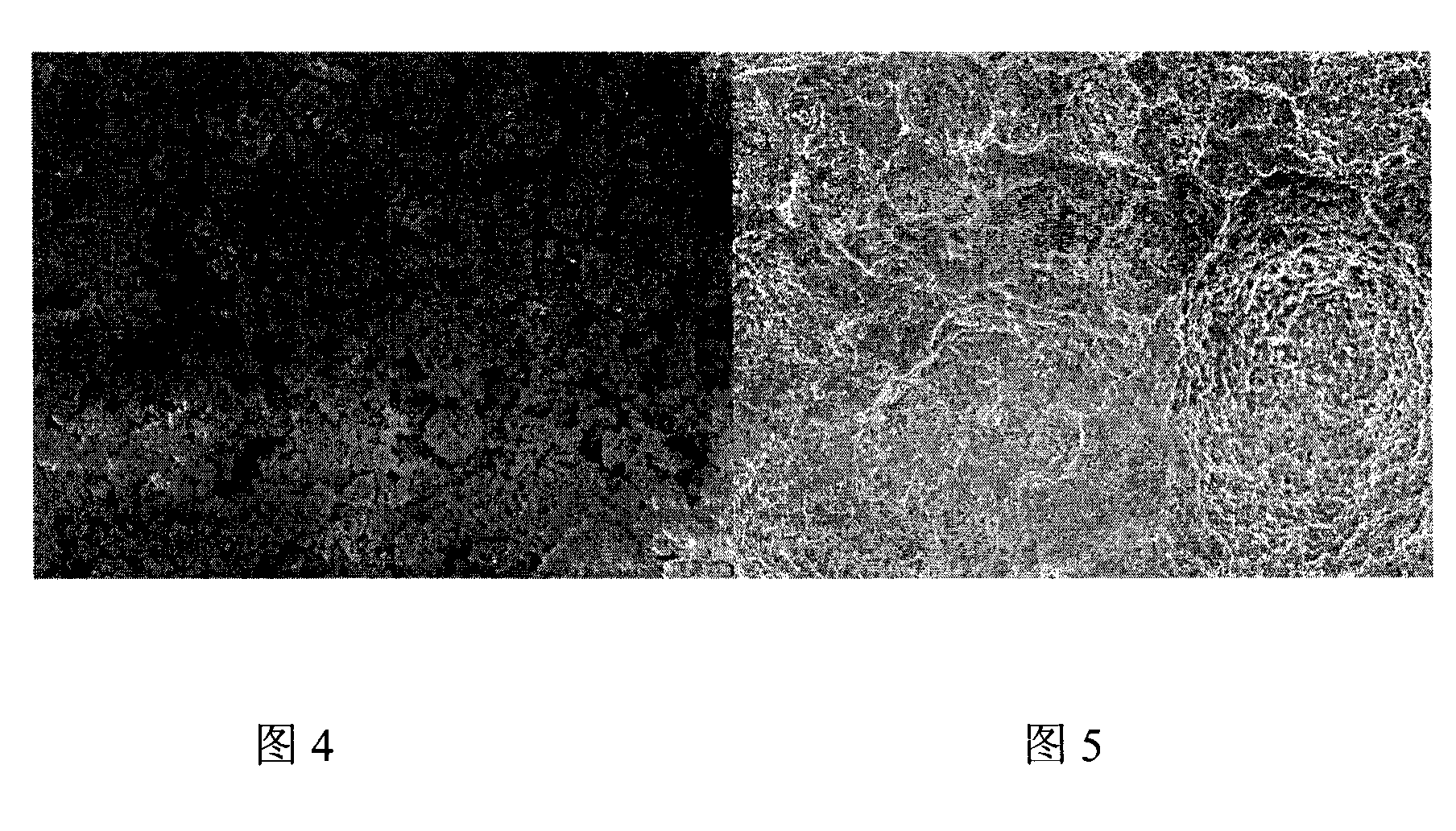

[0035] The scanning electron microscope image of the surface of the polished and coated aluminum plate base is as follows figure 2 (magnification 1500 times, scale bar: 10μm / cm) and Figure 4 (mag...

Embodiment 2

[0037] Use 300# (particle size: 111.1μm) sandpaper with a grinding pressure of 2.5KPa, and apply a hydrophilic polymer coating after grinding. Weigh 0.5g polyvinyl alcohol (polymerization degree 2500, alcoholysis degree 88%), 0.5g polyvinylpyrrolidone K-30, 0.25g silicon dioxide (particle diameter is 10~20nm), put into 50ml Erlenmeyer flask, add 23.75g distilled water, 5ml ethanol, stir for 6-8 hours to fully dissolve. Cut the aluminum plate into 10×10cm 2 , washed with acetone and distilled water successively, and dried. On the glue leveler, the coating composition is coated on the aluminum plate by the spin coating method, and the coating amount is 2.5g / m by controlling the speed of the glue leveler 2 . Bake at 200°C for 0.5 hours, measure the contact angle, Ra value and adhesion of the plate, see Tables 1, 2 and 3.

Embodiment 3

[0039] Use 400# (grain size: 155.6 μm) sandpaper with a grinding pressure of 0.75KPa to polish the surface of the aluminum plate base. After sanding, apply hydrophilic polymer paint. Weigh 1g of gelatin and 0.25g of silicon dioxide (with a particle size of 2-3μm), put them into a 50ml Erlenmeyer flask, add 23.75g of distilled water, and stir for 6-10 hours to fully dissolve them. Cut the aluminum plate into 10×10cm 2 , washed with acetone and distilled water successively, and dried. On the glue leveler, the coating composition is coated on the aluminum plate by the spin coating method, and the coating amount is 1.5g / m by controlling the speed of the glue leveler 2 . Bake at 150°C for about 1 hour, and measure the contact angle, Ra value and adhesion of the plate, see Tables 1, 2 and 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com