Synthetic paper pattern processing method and its equipment

A processing method and technology for synthetic paper, applied in the field of synthetic paper processing, can solve the problems of poor writing and printing performance, poor surface permeability and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

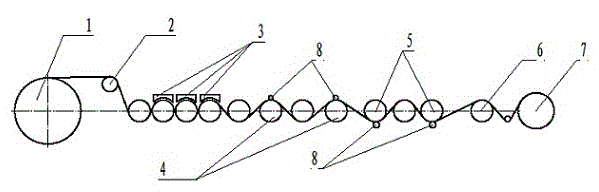

[0020] The present invention will be further described below in conjunction with accompanying drawing and process flow.

[0021] As shown in the figure, an equipment for patterning synthetic paper base paper according to the present invention includes a heater 3 , a primary stretching unit 4 , a secondary stretching unit 5 and a cooling device 6 . The embodiment shown in the drawings has installed two stretching units 4,5 in sequence.

[0022] The heater 3 is composed of three heating steel rollers, and the base paper is half-wound around each heating steel roller in an S-shape. The three heating steel rollers are all hollow cylinders, and the shafts at both ends are equipped with liquid inlets and outlets, and heating oil is injected into the heating roller cavity through the liquid inlets and outlets. A thermal insulation cover is arranged above the heating roller.

[0023] Auxiliary steel rolls can be set before and after the heater 3, the front auxiliary steel roll toget...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com