Method for adjusting and controlling chlorate and nitrate content in tobacco extract

A technology for nitrate content and tobacco extraction, which is applied in the fields of tobacco, tobacco preparation, and tobacco treatment. It can solve the problems of chemical agent extraction or extract residue, tobacco aroma components are easily damaged, and the process is complicated. It achieves low cost, The effect of easy operation control, simple process and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

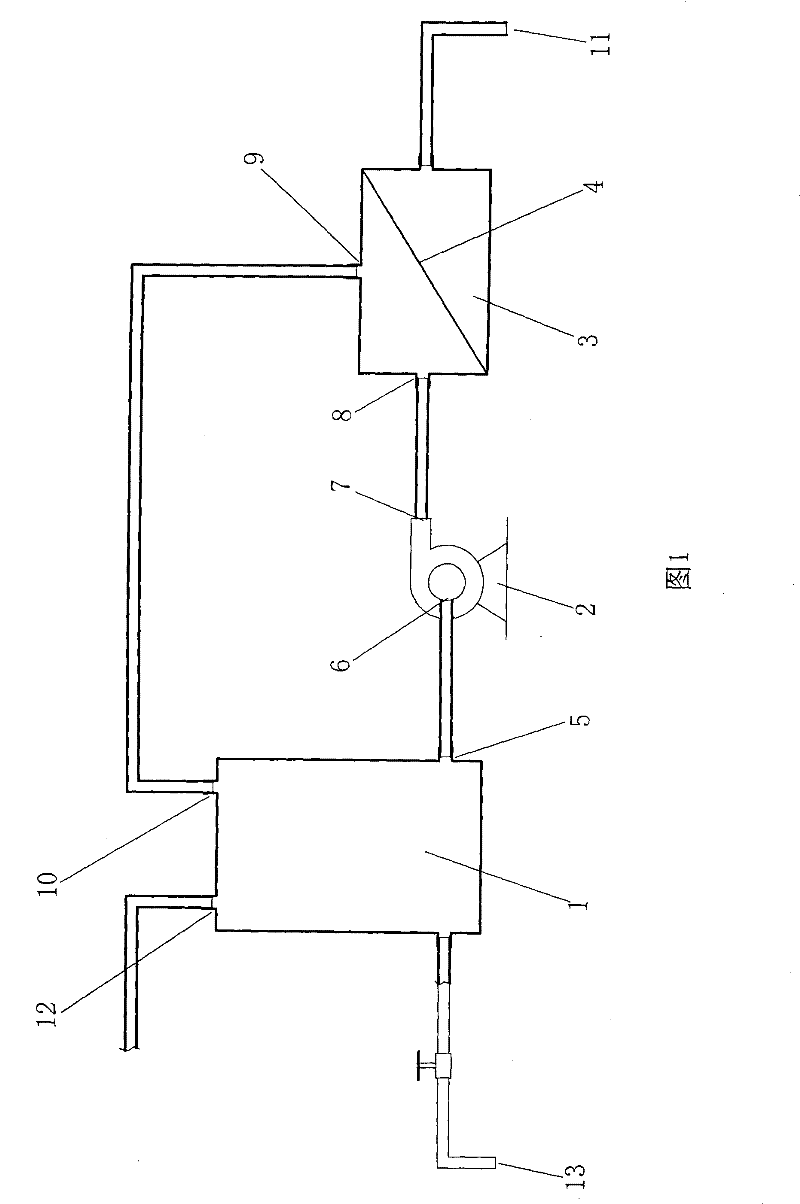

Image

Examples

Embodiment 1

[0017] The method for controlling chlorine and nitrate content in tobacco extraction or extract is characterized in that: 10.00 kg of tobacco raw material extraction or extract in the production of reconstituted tobacco leaves by papermaking method is used, wherein the solid content is 70.5%, and the chlorine content is 1.62%. The nitrate content is 1.12%; dissolve it in 70.00kg of water and stir evenly, the concentration after dilution is about 8.8%; put the diluted solution into a nanofiltration membrane circulation device for circulation filtration, and the operating temperature is controlled at ≤40°C. The operating pressure is controlled at ≤ 35Mpa; 33.62kg of the retained solution after removal of chlorine and nitrate is obtained by the nanofiltration membrane, and its concentration is 19.3%; 9.67Kg of extract is obtained after the concentrated solution is concentrated, wherein the solid content is 66.5%. The content is 0.16%, and the nitrate content is 0.38%, which is use...

Embodiment 2

[0020] The method for controlling chlorine and nitrate content in tobacco extraction or extract is characterized in that: 10.00 kg of tobacco raw material extraction or extract in the production of reconstituted tobacco leaves by papermaking method is used, wherein the solid content is 65.9%, and the chlorine content is 1.67%. The nitrate content is 0.92%; dissolve it in 90.00kg of water and stir evenly, the concentration after dilution is about 6.6%; put the diluted solution into a nanofiltration membrane circulation device for circulation filtration, and the operating temperature is controlled at ≤40°C. The operating pressure is controlled at ≤ 35Mpa; 28.36kg of the retained solution after removing chlorine and nitrates is obtained by the nanofiltration membrane, and its concentration is 21.9%; 8.22Kg of extract is obtained after the concentrated solution is concentrated, wherein the solid content is 75.5%. The content is 0.08%, and the nitrate content is 0.32%. It is used as...

Embodiment 3

[0023] The method for adjusting and controlling chlorine and nitrate content in tobacco extraction or extract is characterized in that: 100.00 kg of tobacco stem raw material extraction or extract solution in the production of reconstituted tobacco leaves by papermaking method, wherein the solid content is 5.62%, and the chlorine content is 0.21% , the nitrate content is 0.14%; because its concentration has met the operating requirements of the nanofiltration membrane circulation device, it is directly put into a nanofiltration membrane circulation device for circulation filtration, and the operating temperature is controlled at ≤40°C and the operating pressure is controlled at ≤35Mpa; Obtain 28.36kg of retentate solution after removal of chlorine and nitrate intercepted by nanofiltration membrane, its concentration is 18.3%; after concentration of the retentate solution, 7.40Kg of extract is obtained, wherein the solid content is 70.1%, and the chlorine content is 0.26% , with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com