Composite process for treatment of inferior residual oil

A combined process and residual oil technology, which is applied in hydrotreating process, hydrocarbon oil treatment, petroleum industry, etc., can solve the problems of frequent catalyst replacement, low catalyst utilization rate, poor fluidity, etc., and achieve wide raw material adaptability and process optimization Optimize and ensure the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

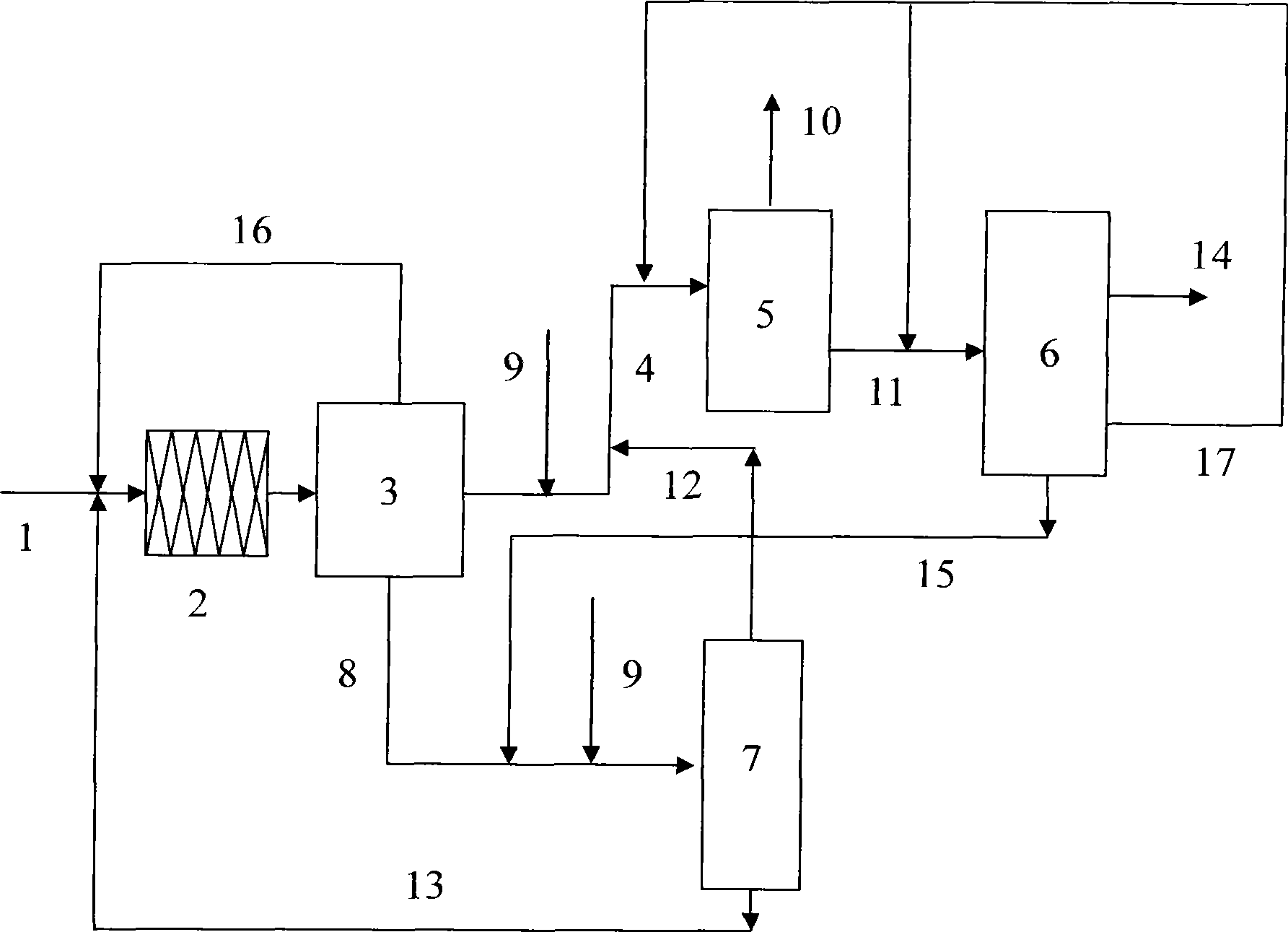

Image

Examples

Embodiment 1

[0038] This example is a reaction process of residual oil hydrogenation using a combined process of solvent deasphalting, ebullating bed, suspension bed and catalytic cracking. Firstly, the residual oil raw material is uniformly mixed with a mixed solvent composed of butane, pentane and a small amount of <145°C naphtha fraction generated by suspension bed hydrogenation in a static mixer, and then enters a two-stage solvent deasphalting device to obtain DAO and deoiled asphalt, DAO is preheated, mixed with hydrogen and sent to the ebullating bed hydroprocessing unit, and the hydrogenation reaction is carried out under the conventional ebullating bed hydrogenation catalyst and process conditions, and the heteroatoms and residues such as sulfur and nitrogen in the raw material are removed. Carbon, the hydrogenation products are separated to obtain gasoline, diesel and hydrogenated tail oil; the ebullated bed hydrogenated tail oil enters the heavy oil catalytic cracking unit for re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com