Rotor spinning machine double-impurity-discharging carding device combined with charge balance and application

A technology of rotor spinning machine and charge balance, which is applied in the direction of continuous winding spinning machine, spinning machine, open-end spinning machine, etc. To avoid clogging and other problems, achieve the effect of good yarn quality consistency, eliminate impurity turning and back-absorption, and reduce nep breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

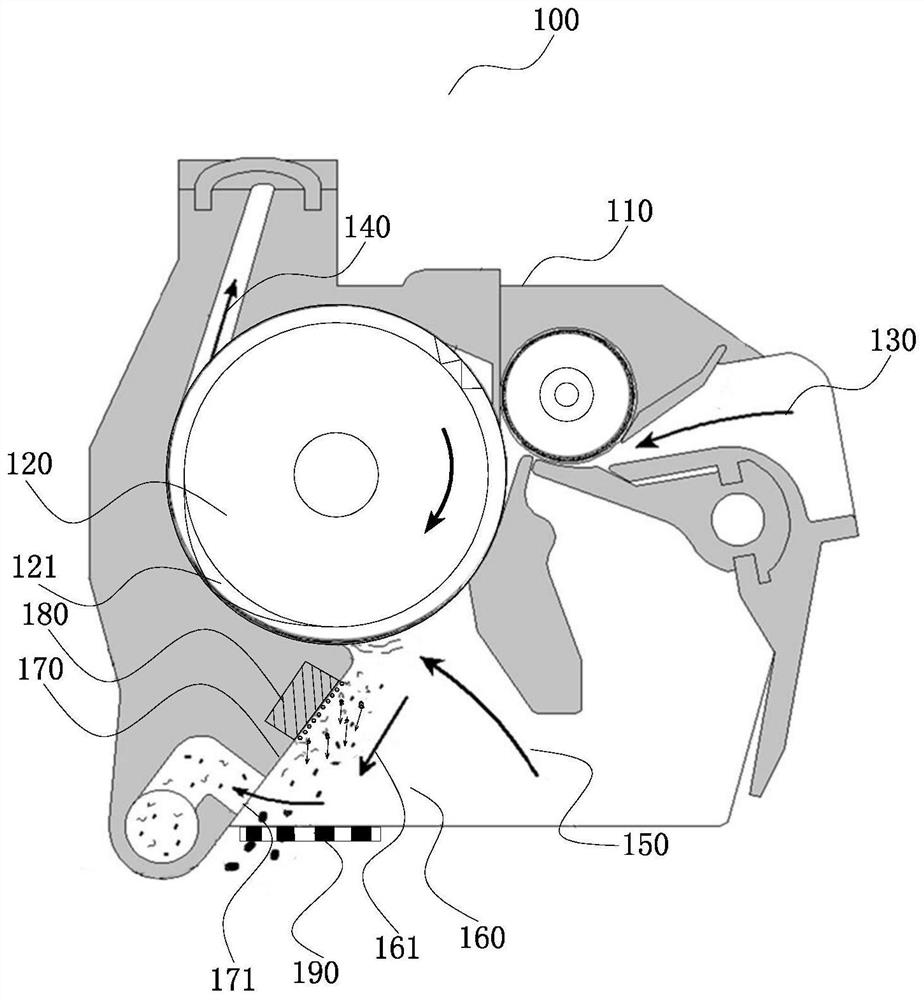

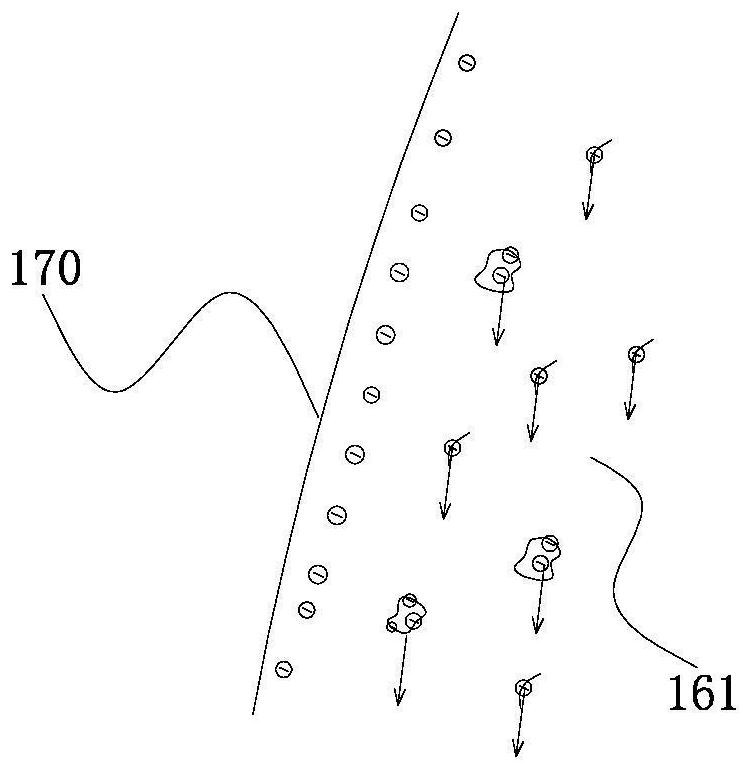

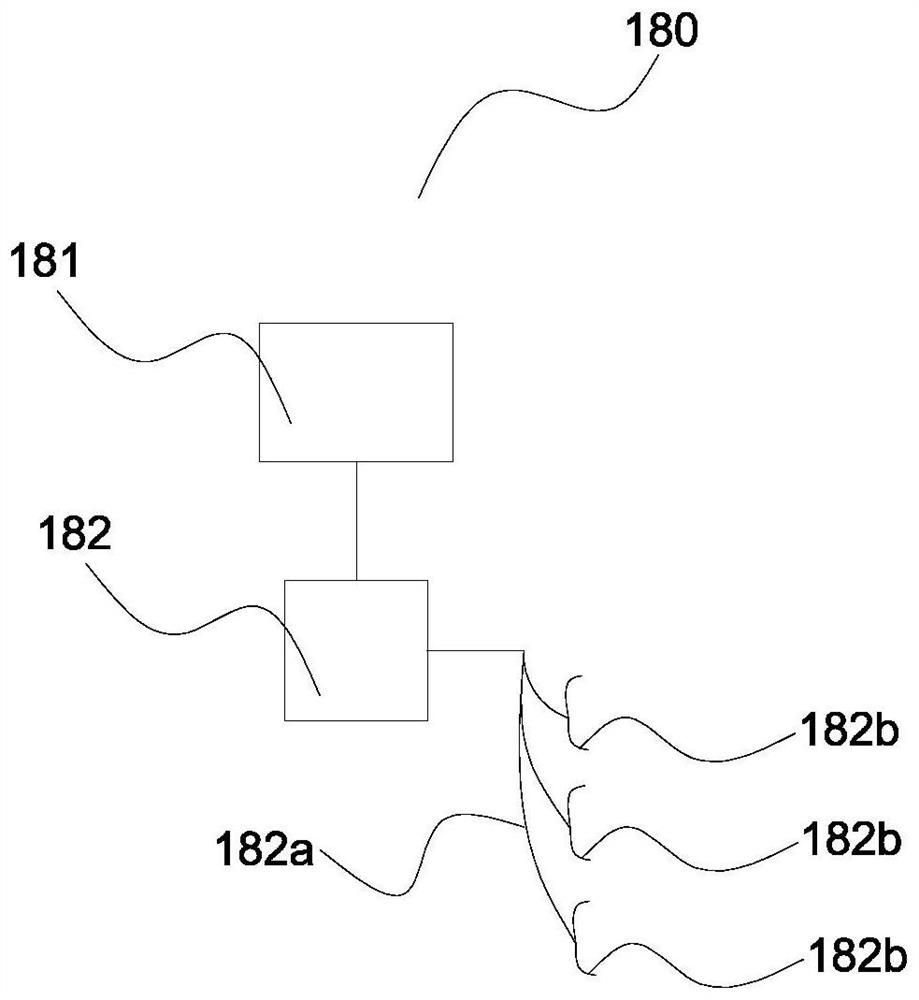

[0046] see figure 1 As shown, the present invention provides a double row and carding device for a rotor spinning machine combined with charge balance.

[0047] The double-row carding device 100 includes a housing 110 provided with a carding cavity, and a carding roller 120 is installed in the carding cavity, and the housing 110 is provided with a sliver feeder that is respectively communicated with the carding cavity. channel 130 and fiber delivery channel 140.

[0048] The left side of the carding roller 120 is provided with a fiber transfer area 121 for transferring the carded sliver. The fiber transfer area 121 is arranged below the fiber delivery channel 140 , and the sliver first passes through the fiber transfer area 121 after carding, and then is transported to the rotor through the fiber delivery channel 140 .

[0049] The fiber conveying channel 140 may include a channel inlet and a channel outlet, the channel inlet is connected to the carding chamber, the directio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com