Air suction assisted multiple impurity removing and carding device of rotor spinning machine and spinning machine

A technology of rotor spinning machine and air extraction device, which is applied to spinning machines, open-end spinning machines, and continuous winding spinning machines, etc., which can solve the problems of high energy consumption of equipment, impossibility of waste removal efficiency, and adaptability of raw materials. Consistency of yarn quality, low energy consumption, low energy consumption, etc., to achieve the effect of good yarn quality consistency, elimination of impurity rollback and wide adaptability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

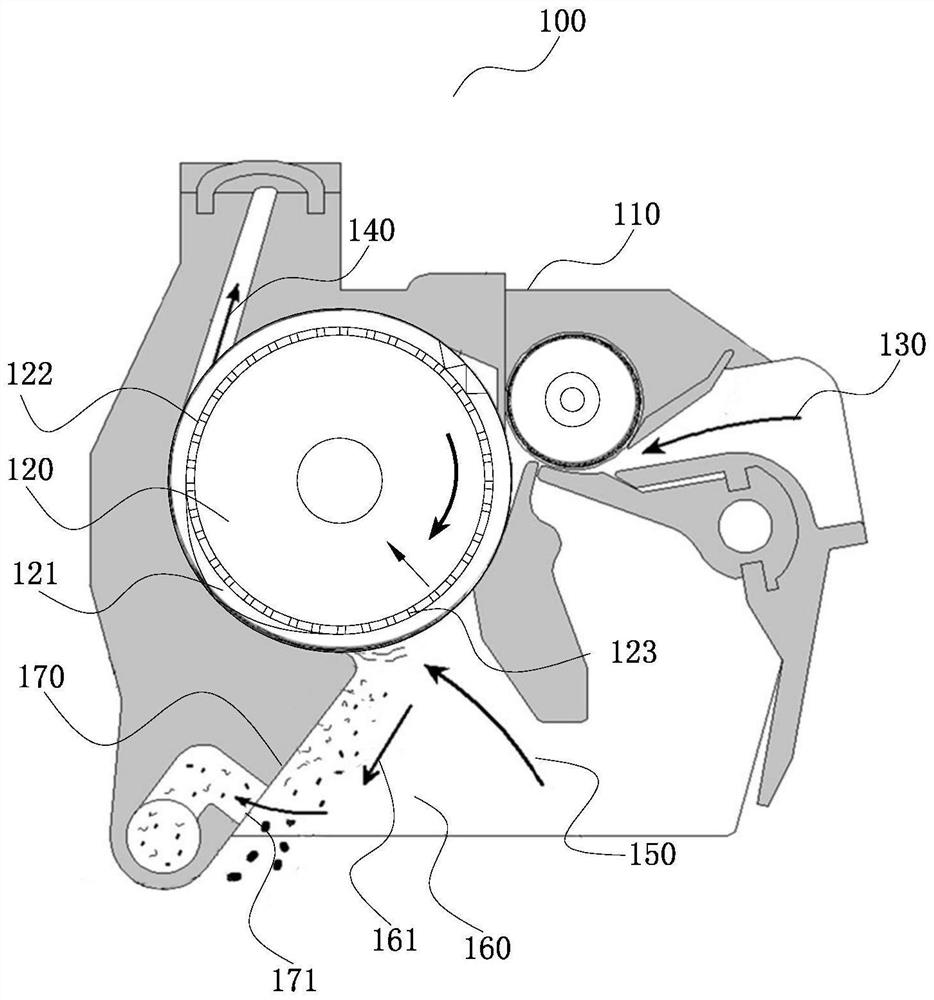

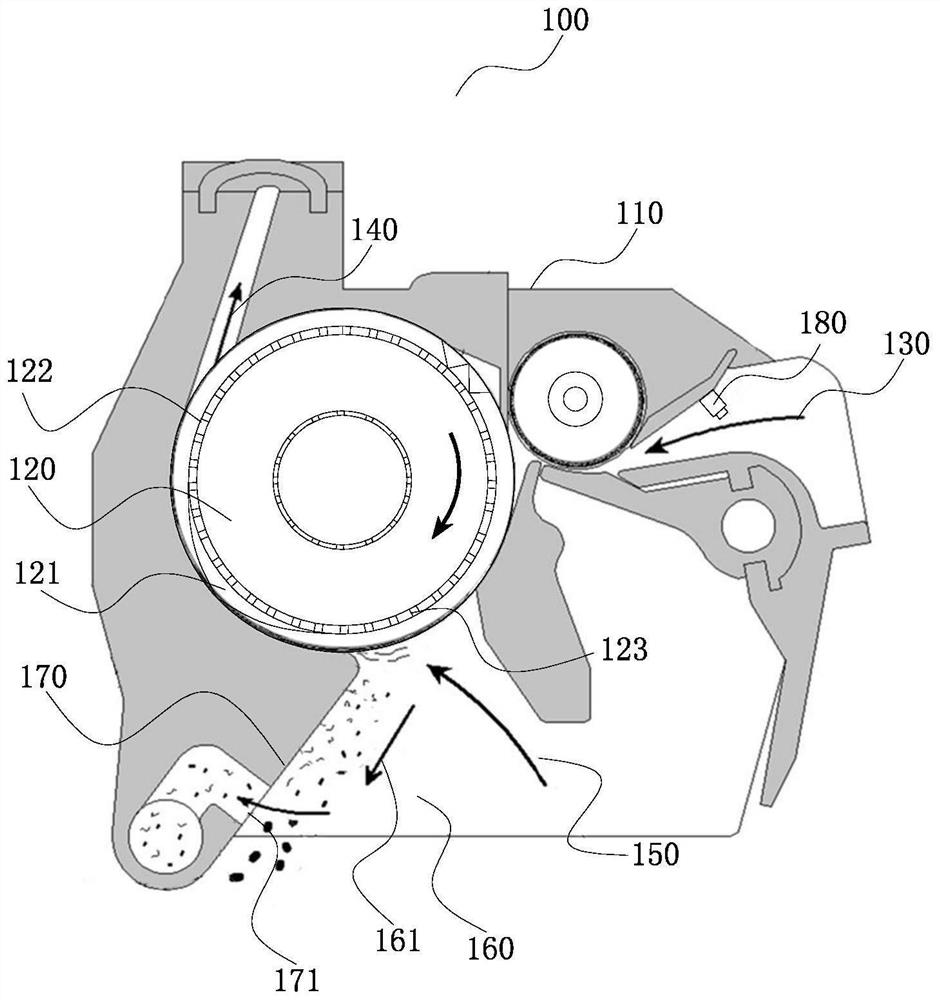

[0050] see figure 1 As shown, it is an air-suction-assisted multi-arrangement carding device for a rotor spinning machine provided by the present invention.

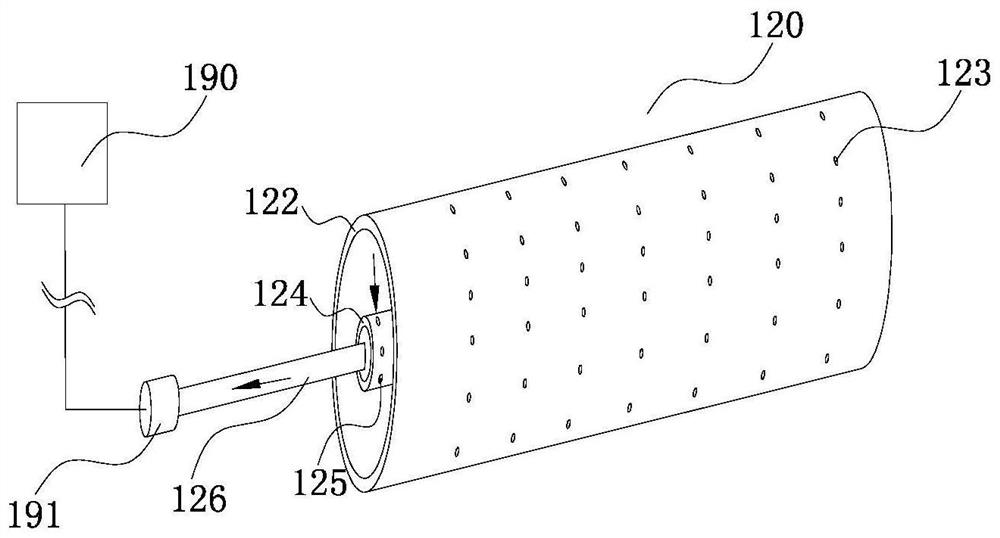

[0051] The air-suction assisted multi-arrangement carding device 100 includes a housing 110 provided with a carding cavity, a carding roller 120 is installed in the carding cavity, and a sliver feeding roller 120 which is respectively communicated with the carding cavity is arranged on the housing 110. Feed channel 130 and fiber delivery channel 140 . The fiber conveying channel 140 may include a channel inlet and a channel outlet, the channel inlet is connected to the carding chamber, the direction of the channel outlet is aligned with the inside of the rotor, and a condensation groove is arranged in the rotor. During spinning, the sliver is sent into the carding chamber through the sliver feeding channel 130 for carding, and the carded fiber enters the interior of the rotor cup through the fiber delivery channel 140, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com