Ginned cotton cleaning machine

A lint cleaning and lint technology, which is applied to fiber cleaning machines and tooth-shaped tools, can solve the problems of fiber length and strength reduction, and achieve the effect of reducing defects, high lint, and simplifying structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The implementation mode of the present invention is illustrated by specific specific examples below, and those who are familiar with this technology can easily understand other advantages and effects of the present invention from the contents disclosed in this description. Obviously, the described embodiments are a part of the present invention. , but not all examples. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

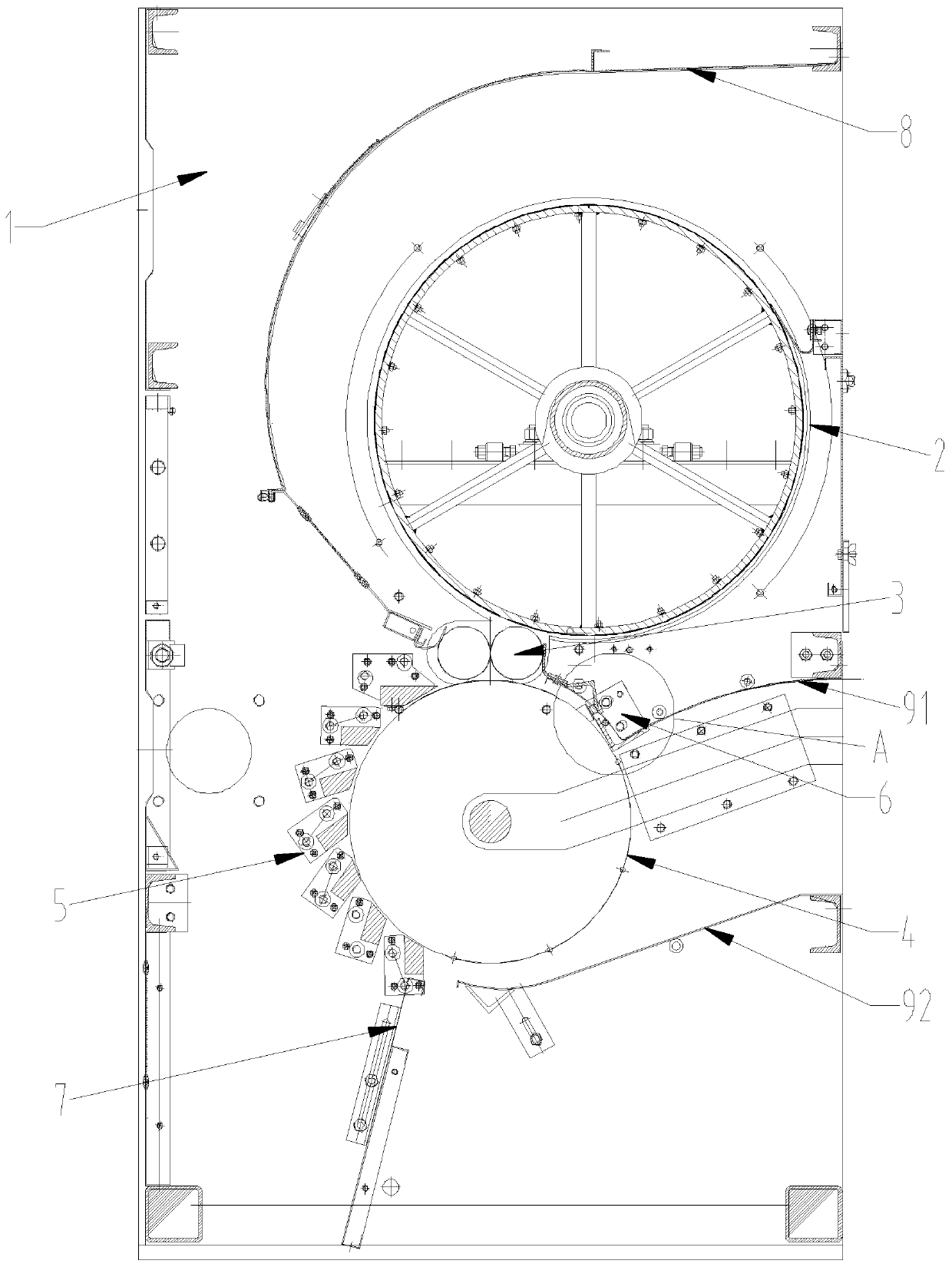

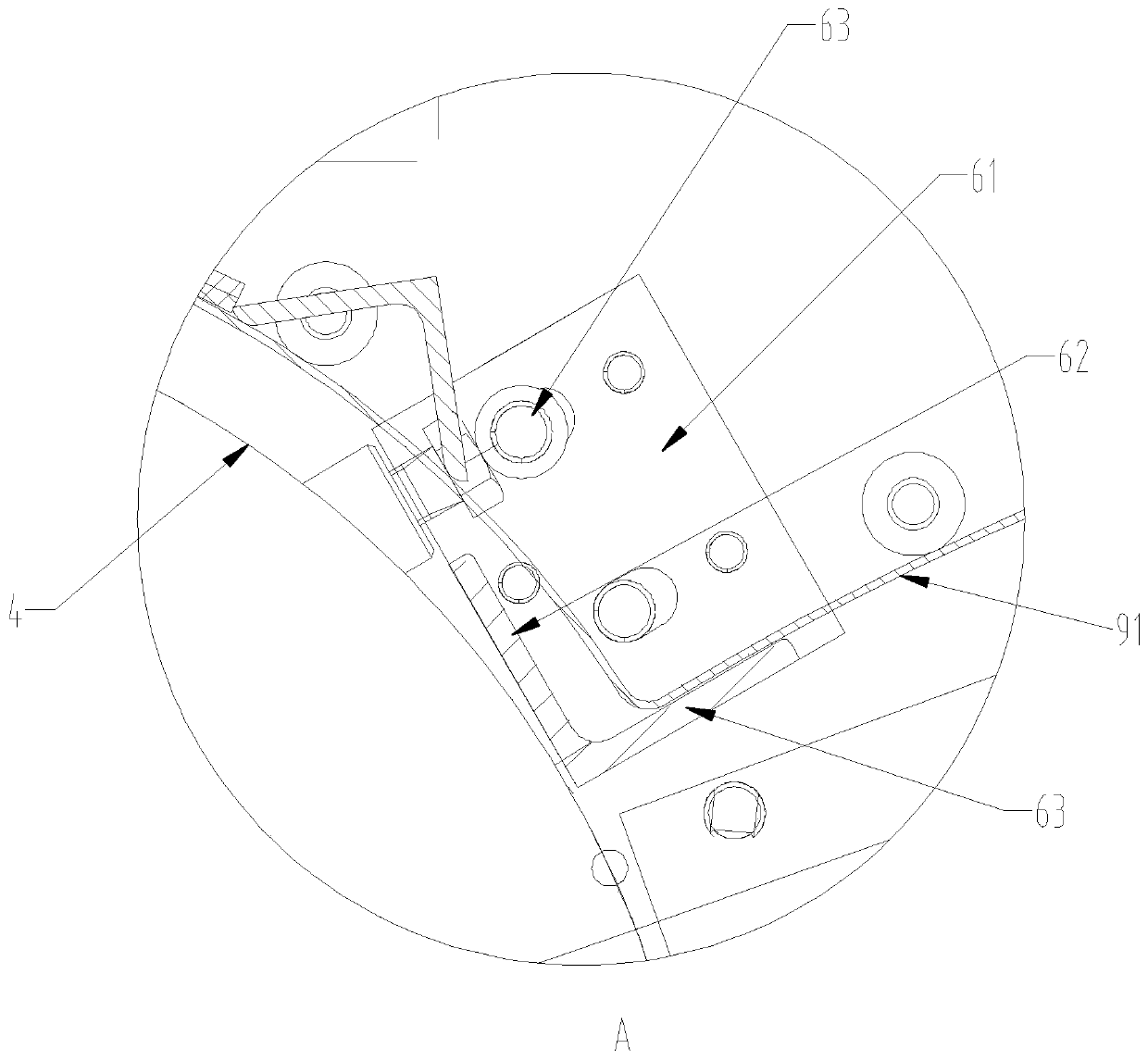

[0025] A lint cleaning machine, combined with figure 1 and figure 2 , consisting of frame 1, dust cage 2, traction roller 3, licker-in roller 4, miscellaneous knife 5 and cotton picker 6, mainly used to remove dust, leaf debris, sterile seeds, broken seeds and large particles in lint Defects and new-born impurities in the ginning process, such as cords, fiber seed chips, etc., improve the inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com