Epoxy resin combination, composite material and preparation method thereof

A technology of epoxy resin and composite material, applied in the field of epoxy resin composition and composite material, can solve the problems of limited application of epoxy resin system, high price, high viscosity, etc. The effect of low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] 1. Put the glass fiber unidirectional fabric flat in the blast drying oven, heat-treat at 100°C for 1 hour to remove moisture, and cut it according to the mold size after cooling;

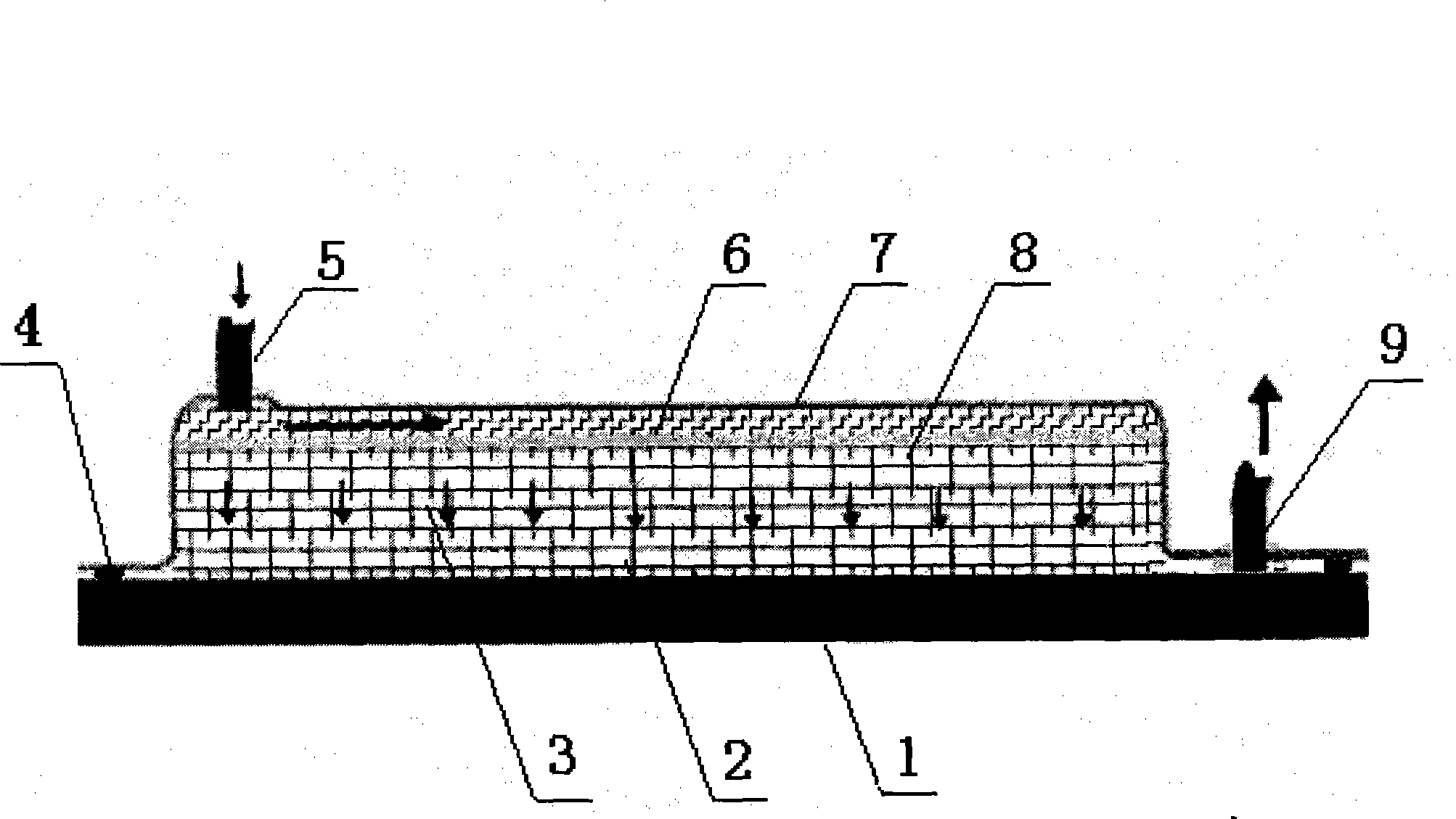

[0061] 2. Clean the surface of the mold, apply a release agent, and place the cut glass fiber unidirectional fabric according to the laying direction: [0] s Sequentially lay in the mould. Then lay out the release cloth and guide cloth in order, insert the injection pipe and exhaust pipe, and finally seal the mold cavity with a vacuum bag, and seal the mold around with sealant;

[0062] 3. Add 10g hexanediol diglycidyl ether and 8g phenyl glycidyl ether low molecular weight epoxy compound to 100g WSR618 epoxy resin, stir them evenly, heat and stir at 70°C for 1 hour, add 2g KH550 after cooling and 0.1g 525, continue mixing. After cooling to 25°C, add 38g of amine curing agent (the mass ratio of isophoronediamine, polyetheramine T403, and 4'4-diaminodicyclohexylmethane is 3:16:1), and sti...

Embodiment 2

[0066] 1. Put the glass fiber two-way fabric flat in the blast drying oven, heat-treat at 100°C for 1 hour to remove moisture, and cut it according to the mold size after cooling;

[0067] 2. Clean the surface of the mold, apply a release agent, and place the cut glass fiber unidirectional fabric in the direction of laying: [+45] s Sequentially lay in the mould. Then lay out the mold release cloth and guide cloth in order, and insert the injection pipe and exhaust pipe, and finally seal the mold cavity with a vacuum bag, and seal the edge of the mold tightly with sealant;

[0068] 3. Repeat steps 3 and 4 in Example 1;

[0069] The tensile strength of the finally measured glass fiber bidirectional fabric / epoxy resin composite along the fiber direction is 450MPa, the tensile modulus is 21GPa, the compressive strength is 404MPa, and the compressive modulus is 25.3Gpa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com