Slag-forming constituent and preparation thereof

A slagging agent and drying technology, which is applied in the field of metallurgy, can solve the problems of low iron grade in steelmaking sludge, secondary pollution of the environment, and high water content, and achieve the goals of reduced consumption of steel materials, improved dephosphorization efficiency, and fast slagging speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 25% by weight of high siliceous manganese ore, 25% by weight of steelmaking sludge, 45% by weight of quartz sand and 5% by weight of magnesium chloride binder are weighed and prepared, and then sent into the mixing mixer, fully mixed After stirring, make elliptical or round pellets of 30mm to 50mm, refer to Table 6 for the drying conditions, and control the moisture content to be less than 1% after drying.

Embodiment 2

[0033] 25% by weight of high siliceous manganese ore, 35% by weight of steelmaking sludge, 35% by weight of quartz sand and 5% by weight of magnesium chloride binder are weighed and prepared, and then sent into the mixing mixer, fully mixed After stirring, make elliptical or round pellets of 30mm to 50mm, refer to Table 6 for the drying conditions, and control the moisture content to be less than 1% after drying.

Embodiment 3

[0035] 25% by weight of manganese ore, 30% by weight of steelmaking sludge, 40% by weight of quartz sand and 5% by weight of magnesium chloride binder are weighed and prepared, and then sent into the mixing mixer, after fully mixing and stirring, Make elliptical or round pellets of 30mm to 50mm, refer to Table 6 for the drying conditions, and control the moisture content to be less than 1% after drying.

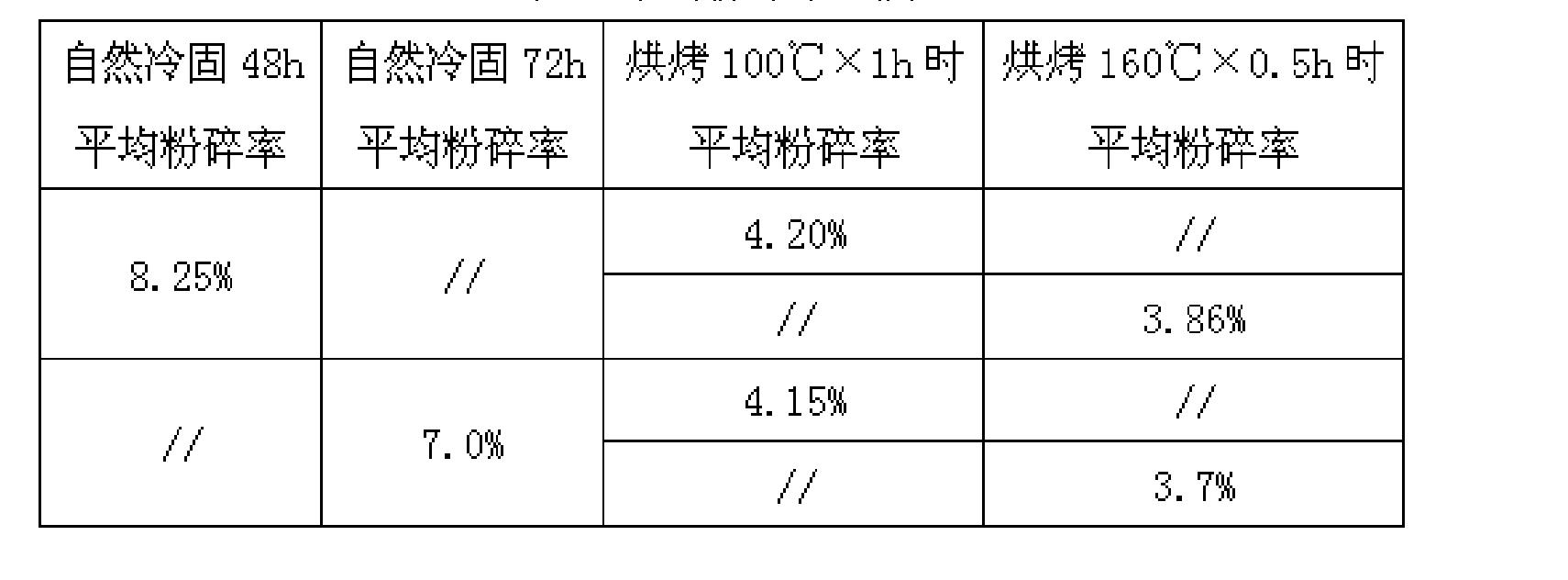

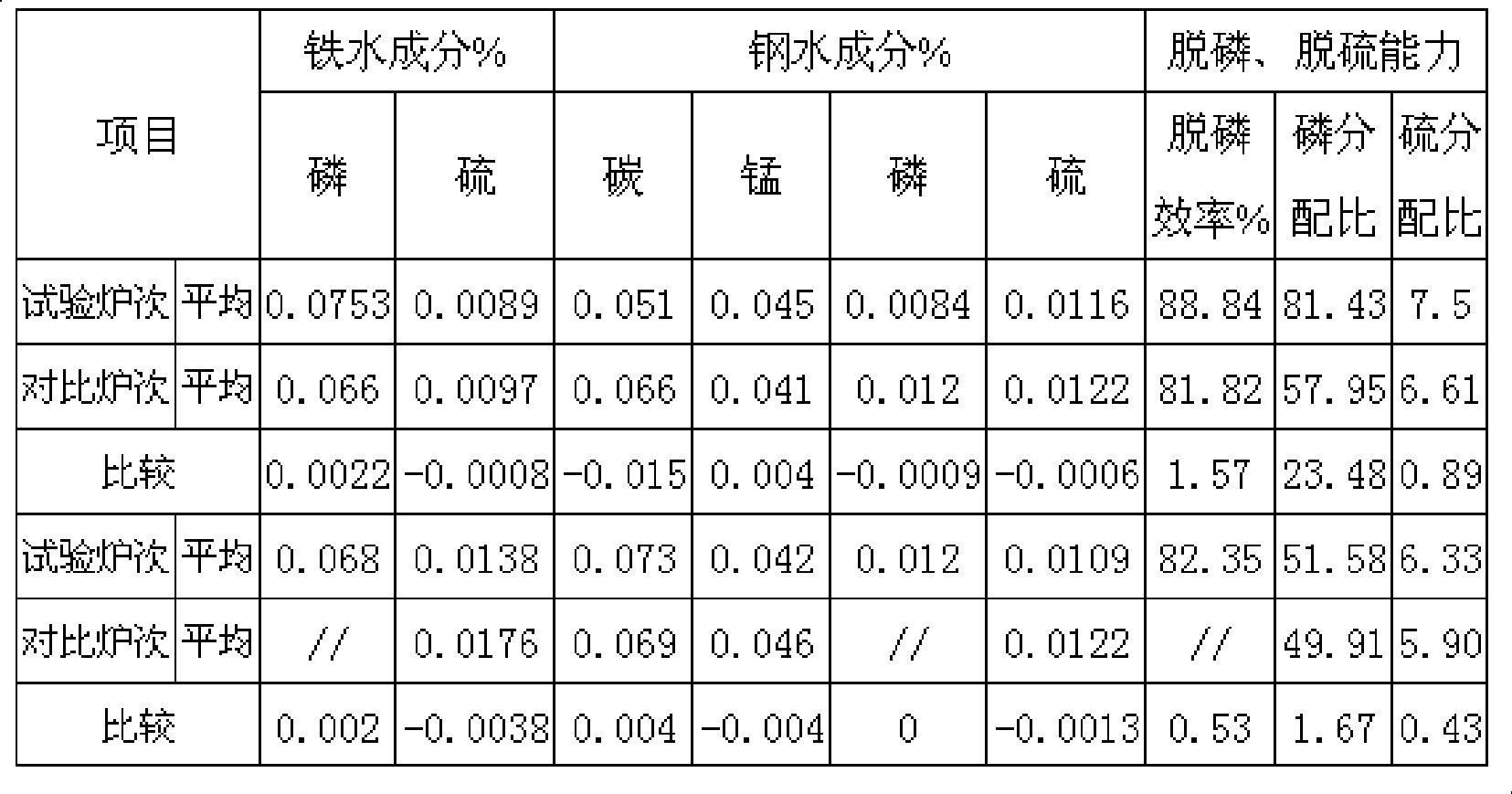

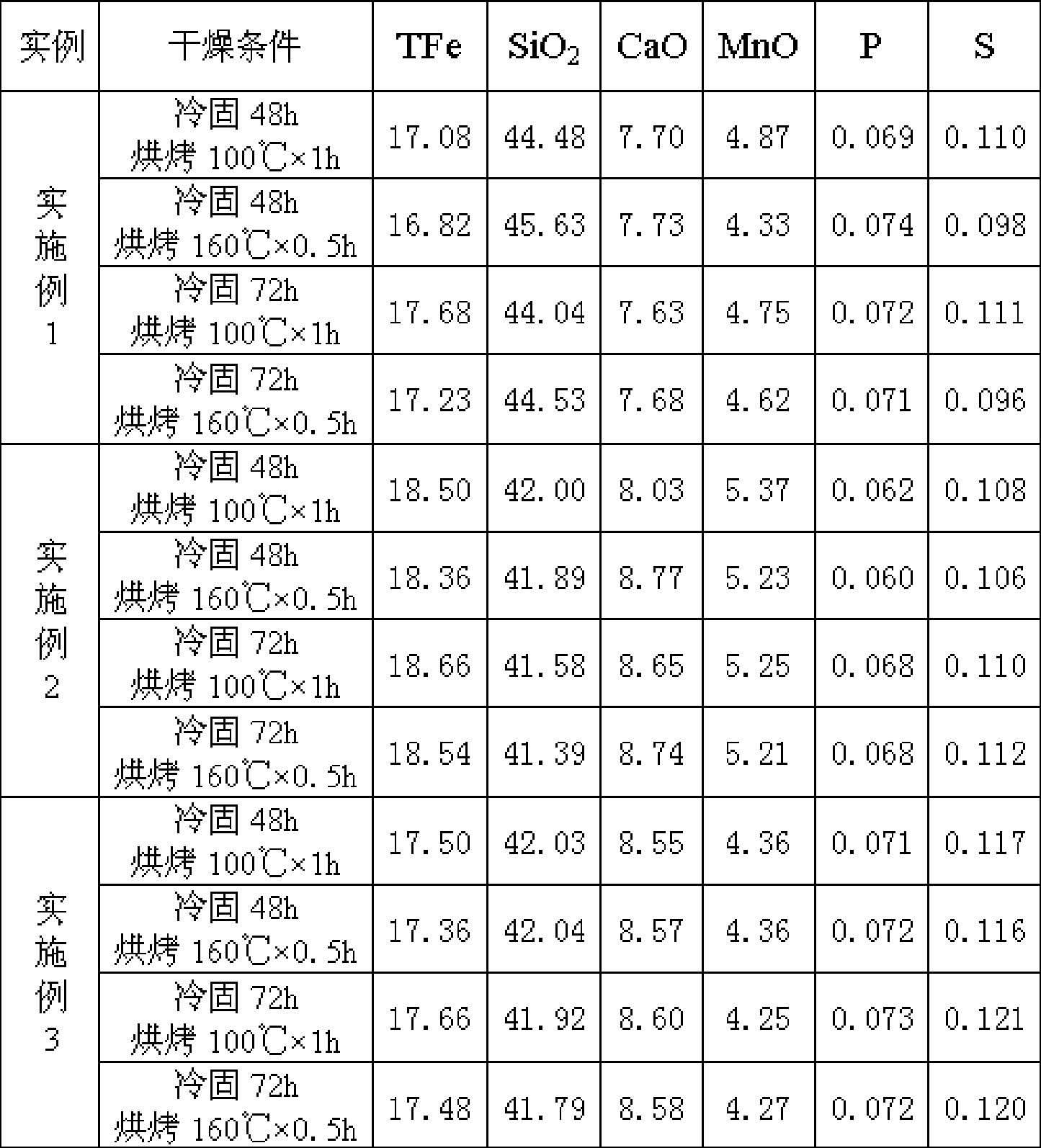

[0036] See Table 5 for the detection of the chemical components of the slagging agents obtained in Examples 1-3, Table 6 for the detection of the pulverization rate, and Table 7 for the smelting effect.

[0037] Table 5 Chemical Composition Detection (%)

[0038]

[0039] After being dried by natural stacking, it is sent to a vertical drying furnace for drying treatment. See Table 6 for the control of drying temperature and drying time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com