Method for dyeing real silk fabric cheese

A dyeing method and technology for silk fabrics, applied in dyeing methods, textiles and papermaking, liquid/gas/vapor yarn/filament processing, etc. Improve stability and efficiency, resolve unwinding and entanglement, and reduce the effect of photochromic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Take the package yarn with a specification of 80S / 2 (raw silk), a quantity of 30 packages, and an emerald green dyed color as an example.

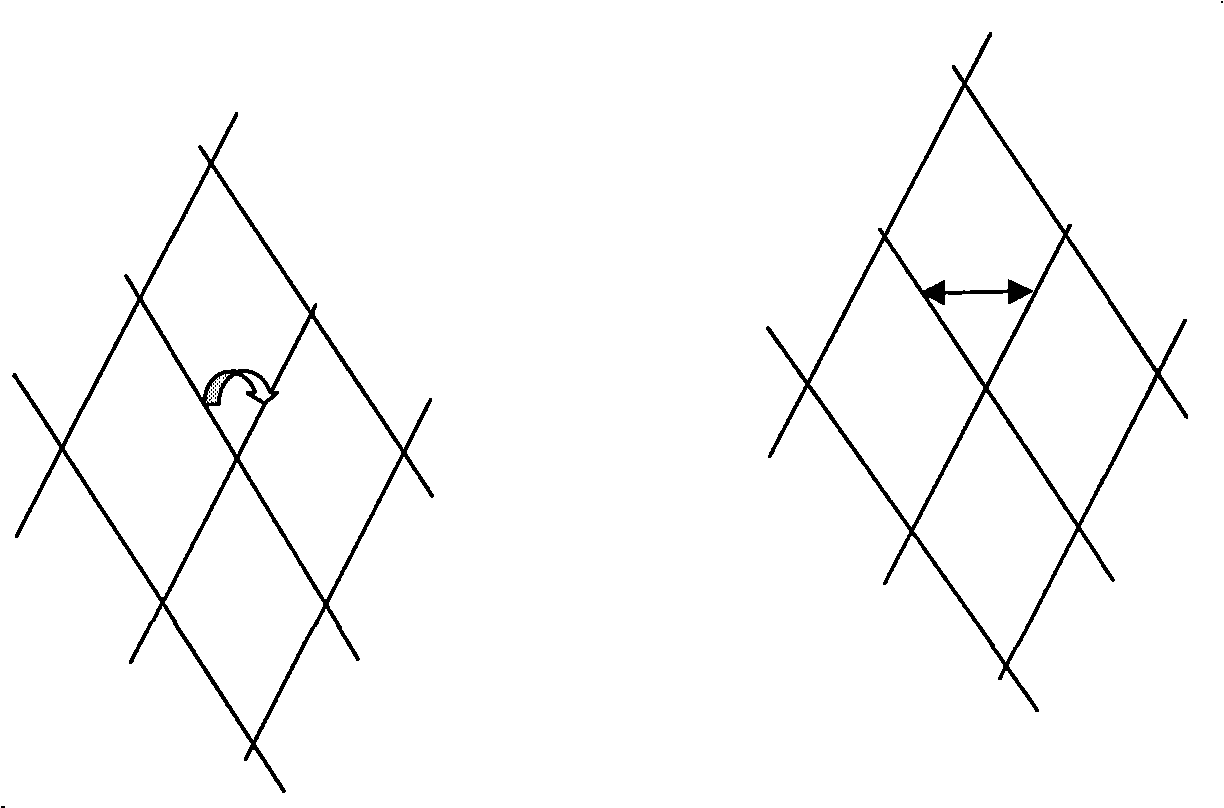

[0026] To loosen the yarn, first loosen the 80S / 2 yarn bobbin purchased from the market on the SSM TW1-W winding machine, and loosen the silk bobbin by digital winding, with a crossing angle of about 30° (such as image 3 As shown), the silk loose bobbin tube is covered with 10g polyester filament, and the density of the raw silk loose bobbin is 0.31g / cm 3 , the weight of a single bobbin is 400g.

[0027] For raw silk refining, add water to the dyeing vat, the bath ratio is 1:10, that is, 1kg of silk is mixed with 10kg of water, and then add soda ash to the dyeing vat at room temperature in an amount of 1g / L, and the refining agent GED produced by BASF China [1] , the addition amount is 0.5g / L, and adding sodium hydrosulfite, the addition amount is 1g / L, and the temperature is raised to 70°C at a rate of 1.5°C / min. .

[0028] For...

Embodiment 2

[0030] Take the package yarn with a specification of 40S (raw silk), a quantity of 80 packages, and a dyed purple package as an example.

[0031] To loosen the yarn, first loosen the 40S yarn bobbin purchased from the market on the SSM TW1-W winding machine, and loosen the silk bobbin by digital winding, with a crossing angle of about 30° (such as image 3 As shown), the silk loose bobbin tube is covered with 10g polyester filament, and the density of the raw silk loose bobbin is 0.31g / cm 3 Density, the weight of a single bobbin is 300g.

[0032] For raw silk refining, add water to the dyeing vat, the bath ratio is 1:10, that is, 1kg of silk is mixed with 10kg of water, and then add soda ash to the dyeing vat at room temperature in an amount of 1g / L, and the refining agent GED produced by BASF China , the addition amount is 0.5g / L, and adding sodium hydrosulfite, the addition amount is 1g / L, the temperature is raised to 98°C at a rate of 1°C / min for treatment, one-way circula...

Embodiment 3

[0035] Take the package yarn with the specification of 80S / 2 (cooked silk), the quantity of 10 tubes, and the dyed blue color as an example.

[0036] To loosen the yarn, first loosen the 80S / 2 bobbin purchased from the market on the SSM TW1-W winder, and loosen the silk by digital winding, with a crossing angle of about 30° (such as image 3 As shown), the silk loose bobbin tube is covered with 10g polyester filament, and the density of the cooked silk loose yarn is 0.39g / cm 3 , the weight of a single bobbin is 500g.

[0037] For dyeing, add 1.08% of remazol dye combination (owf, based on fabric weight) and leveling agent pingmazol NF produced by BASF China to the dye vat at room temperature. 0.5g / L, heat up to 40°C at a rate of 1.2°C / min, then add half of the amount of Yuanming powder, the amount added is 20g / L, then keep warm for 30min, and then continue to heat up to 60°C at a rate of 0.8°C / min Finally, add the other half of sodium glutamate, the addition amount is 20g / L,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com