Silk fabric dyeing method and equipment

A technology for fabric dyeing and silk, applied in dyeing methods, textile fixing chemicals, textiles and papermaking, etc., can solve the problems of affecting the dyeing performance of silk fabrics, reducing the utilization rate of dyestuffs, accelerating the hydrolysis of dyestuffs, etc., so as to improve the utilization rate of dyestuffs , Eliminate layer difference and migration, and reduce damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

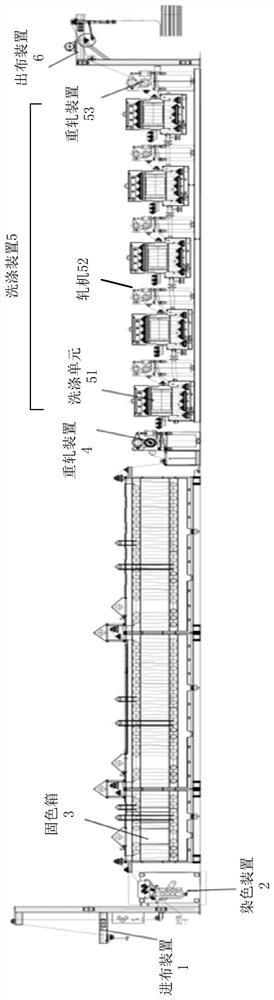

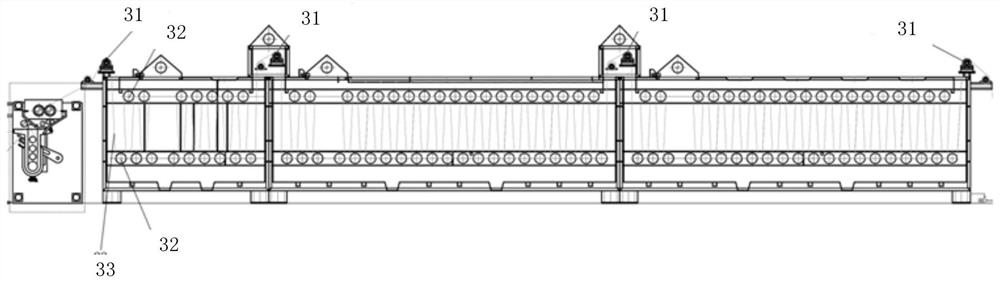

[0033] This embodiment provides a continuous tie-dyeing device that can be used to implement the silk fabric dyeing method. refer to figure 1 , The continuous tie-dyeing equipment includes a cloth feeding device 1, a dyeing device 2, a color fixing box 3, a rerolling device 4, a washing device 5, and a cloth outlet device 6 arranged in sequence.

[0034] Wherein, the cloth feeding device 1 is used to receive and flatten the silk fabric to be dyed, and send the silk fabric to the dyeing device 2 . The dyeing device 2 can pad the silk fabric. Wherein, the dyeing device 2 can be provided with a uniform padding car for padding the silk fabric. Specifically, the dye liquor used for dyeing the silk fabric can be pre-configured, and the dye liquor can be added into the trough of the padder. Wherein, the content of reactive dye in the dyeing liquor is 0.1g / l-100g / l, and the content of alkali is 0.1g / l-20g / l.

[0035] The cloth feeding device 1 can be provided with a cloth feeding ...

Embodiment 2

[0052] Dyeing object: 100% silk fabric.

[0053] Configure the aqueous solution containing reactive black G with a concentration of 60g / L and sodium carbonate with a concentration of 8g / L as the dye solution.

[0054] The dye liquor is added into the feed tank of the dyeing device 2 through an automatic feeding system. Set the operating parameters of the continuous tie-dyeing equipment, including the cloth feeding speed of the cloth feeding device 1, the rotation speed of the cloth guide roller 32, the temperature in the color fixing box 3, the target cloth surface tension, etc. Wherein, the temperature of the color fixing box is set at 95°C. Set the target fabric tension to 1kg. The cloth feeding speed of the cloth feeding device 1 and the rotating speed of the cloth guide roller 32 are set so that the residence time of the 100% silk fabric in the color fixing box 3 is 180s, and the surface tension of the 100% silk fabric is maintained at 1kg.

[0055] Start the continuous...

Embodiment 3

[0062] Dyeing object: fabrics containing 95% silk and 5% wool.

[0063] Configure the aqueous solution containing reactive black G with a concentration of 20g / L and sodium carbonate with a concentration of 5g / L as the dye solution.

[0064] The dye liquor is added into the feed tank of the dyeing device 2 through an automatic feeding system. Set the operating parameters of the continuous tie-dyeing equipment, including the cloth feeding speed of the cloth feeding device 1, the rotation speed of the cloth guide roller 32, the temperature in the color fixing box 3, the target cloth surface tension, etc. Wherein, the temperature of the color fixing box is set at 90°C. Set the target fabric tension to 1.2kg. The cloth feeding speed of cloth feeding device 1 and the rotating speed of cloth guide roller 32 are set so that the residence time of the fabric containing 95% silk and 5% wool in the color fixing box 3 is 60s, and the fabric containing 95% silk and 5% wool is The surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com