Antiaging method for rice product-mashu

An anti-aging and mochi technology, applied in food preservation, baked food, food preparation and other directions, can solve the problems of starch aging, affecting product quality and shelf life, etc., and achieve the effect of good anti-aging effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

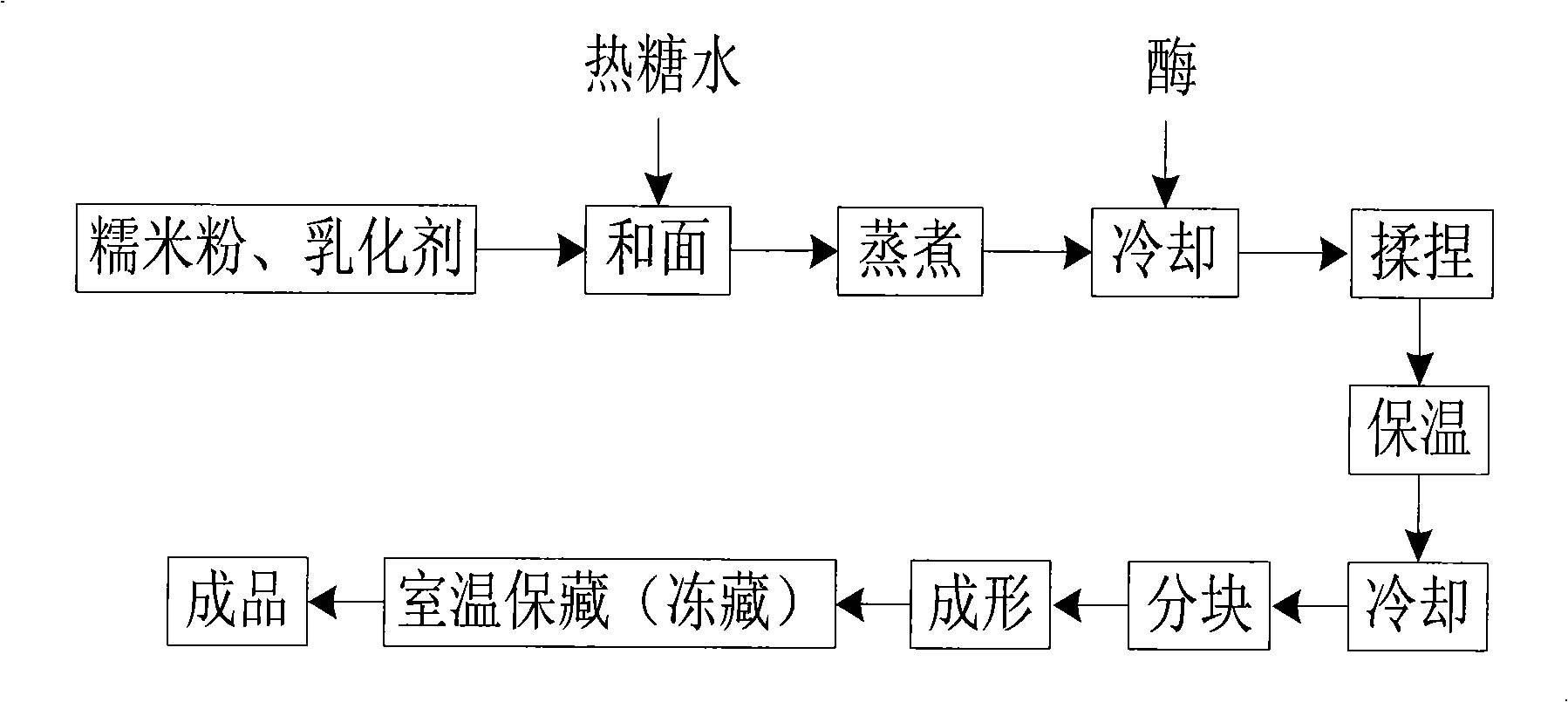

Method used

Image

Examples

Embodiment 1

[0027] According to the production process of mochi in the manual, 2000 g of glutinous rice flour is weighed, and the addition amount of water is respectively 90%, 100%, 110%, 120%, and 130%. The amount of added sugar, emulsifier and enzyme used (in total powder amount) are 20%, 1%, 0.01% respectively. The samples were stored at room temperature (20°C) and frozen storage (-18°C) for 2 weeks, and the hardness of mochi was measured with a texture analyzer. Generally speaking, under the same moisture content, the smaller the hardness, the softer the product and the better the taste. The specific results are shown in Table 1

[0028] Table 1 Effects of different water additions on the hardness of mochi

[0029]

Embodiment 2

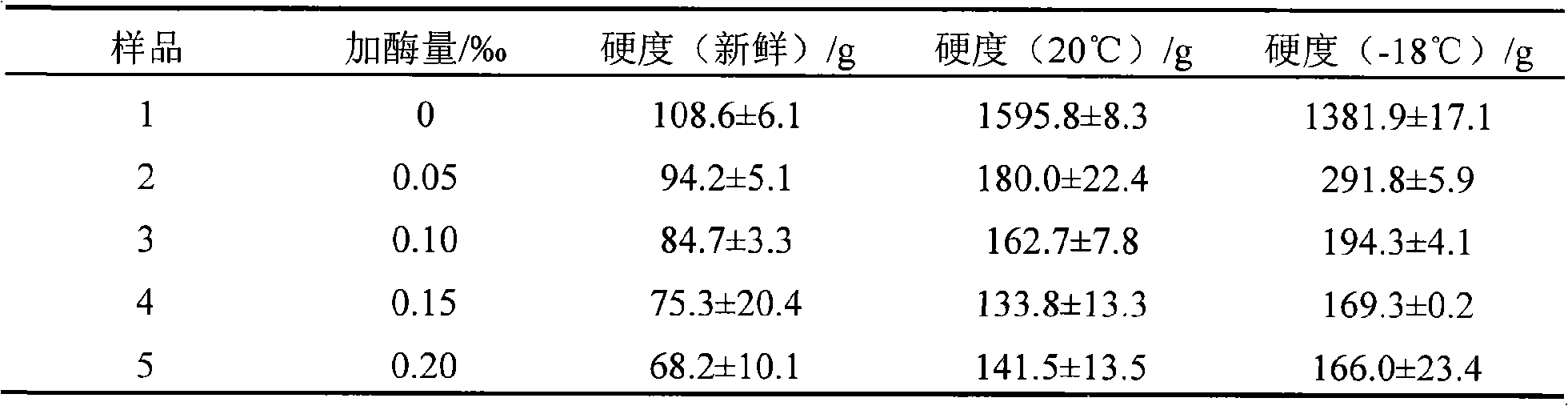

[0031] According to the production process of mochi in the manual, 2000 g of glutinous rice flour was weighed, and the addition amounts of maltogenic amylase were 0%, 0.005%, 0.01%, 0.015%, and 0.02%, respectively. The amount of added sugar, emulsifier and water used (in total powder amount) are 20%, 1%, 110% respectively. The samples were stored at room temperature (20°C) and frozen storage (-18°C) for 2 weeks, and the hardness of mochi was measured with a texture analyzer. The specific results are shown in Table 2

[0032] Table 2 Effect of maltogenic amylase addition on product hardness

[0033]

Embodiment 3

[0035] According to the production process of mochi in the manual, 2000 g of glutinous rice flour was weighed, and the addition amount of emulsifier was 0%, 0.5%, 1%, 1.5%, and 2%, respectively. The amount of added sugar, maltose amylase and water used (in total powder amount) are 20%, 0.01%, 110% respectively. The samples were stored at room temperature (20°C) and frozen storage (-18°C) for 2 weeks, and the hardness of mochi was measured with a texture analyzer. See Table 3 for details

[0036] Table 3 Effect of emulsifier addition amount on product hardness

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com