Uses of allyloxy hydroxide sodium dimercaptosulphanate in transparent MBS resin for PVC

A transparent technology of sodium allyloxy hydroxypropyl sulfonate, applied in the application field of reactive emulsifiers in MBS resins, can solve the problem of reducing the spray drying rate, affecting the stability of the MBS intermediate emulsion, and increasing the labor intensity of the spray tower And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

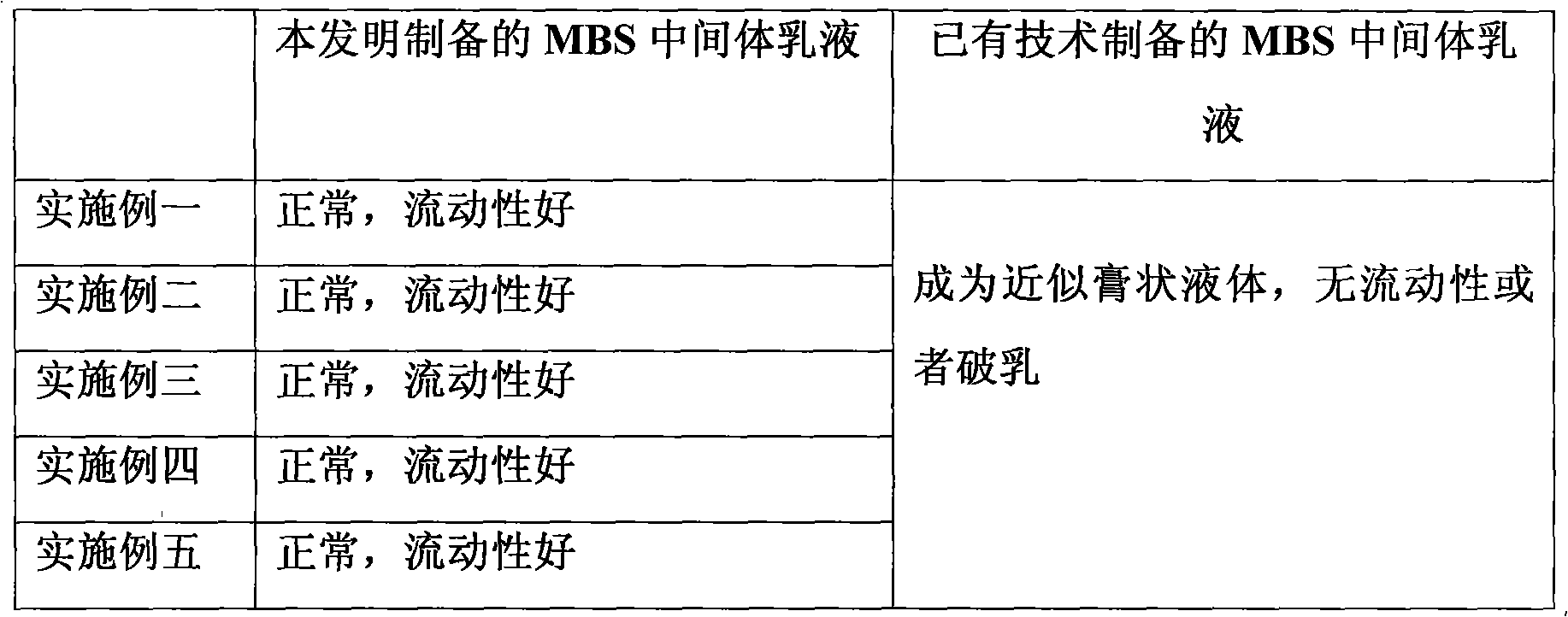

Examples

Embodiment 1

[0010] Add soft water 840kg, one section of emulsifier allyloxy hydroxypropyl sulfonate sodium 2.08kg, one section of monomer (methyl methacrylate 416kg, styrene 936kg and butadiene 728kg) in reactor, seal reactor, heat up, Nitrogen protection, when the temperature rises to 49°C, add an initiator (potassium persulfate or ammonium persulfate 20.8kg) to initiate the reaction. After the reaction starts, the temperature rises, and the cooling water is turned on to control the reaction temperature below 65°C. After the completion, when the temperature dropped to 50°C, add 2.08kg of two-stage emulsifier allyloxy hydroxypropyl sulfonate sodium, two-stage monomer (416kg of methyl methacrylate, 936kg of styrene and 728kg of butadiene), and start the second stage. paragraph response. After the reaction starts, the temperature rises, and the cooling water is turned on to control the reaction temperature not to exceed 65°C. After the reaction is completed, the temperature is lowered to ob...

Embodiment 2

[0012] Add soft water 840kg, one section of emulsifier allyloxy hydroxypropyl sulfonate sodium 6.24kg, one section of monomer (methyl methacrylate 416kg, styrene 936kg and butadiene 728kg) in reactor, seal reactor, heat up, Nitrogen protection, when the temperature rises to 49°C, add an initiator (potassium persulfate or ammonium persulfate 20.8kg) to initiate the reaction. After the reaction starts, the temperature rises, and the cooling water is turned on to control the reaction temperature below 65°C. After completion, when the temperature drops to 50°C, add 6.24kg of the second-stage emulsifier allyloxy hydroxypropyl sulfonate sodium, the second-stage monomer (416kg of methyl methacrylate, 936kg of styrene and 728kg of butadiene), and start the second stage. paragraph response. After the reaction starts, the temperature rises, and the cooling water is turned on to control the reaction temperature not to exceed 65°C. After the reaction is completed, the temperature is lower...

Embodiment 3

[0014] Add soft water 840kg, one section of emulsifier allyloxy hydroxypropyl sulfonate sodium 10.4kg, one section of monomer (methyl methacrylate 416kg, styrene 936kg and butadiene 728kg) in reactor, seal reactor, heat up, Nitrogen protection, when the temperature rises to 49°C, add an initiator (potassium persulfate or ammonium persulfate 20.8kg) to initiate the reaction. After the reaction starts, the temperature rises, and the cooling water is turned on to control the reaction temperature below 65°C. After the completion, when the temperature dropped to 50°C, add 10.4kg of the second-stage emulsifier allyloxy hydroxypropyl sulfonate sodium, the second-stage monomer (416kg of methyl methacrylate, 936kg of styrene and 728kg of butadiene), and start the second stage. paragraph response. After the reaction starts, the temperature rises, and the cooling water is turned on to control the reaction temperature not to exceed 65°C. After the reaction is completed, the temperature is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com