Vacuum power cable

A power cable and vacuum technology, which is applied in the direction of power cables, insulated cables, rigid pipe cables, etc., can solve the problems of increasing the amount of insulating materials, and achieve the effects of less consumables, simple manufacture, and less energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

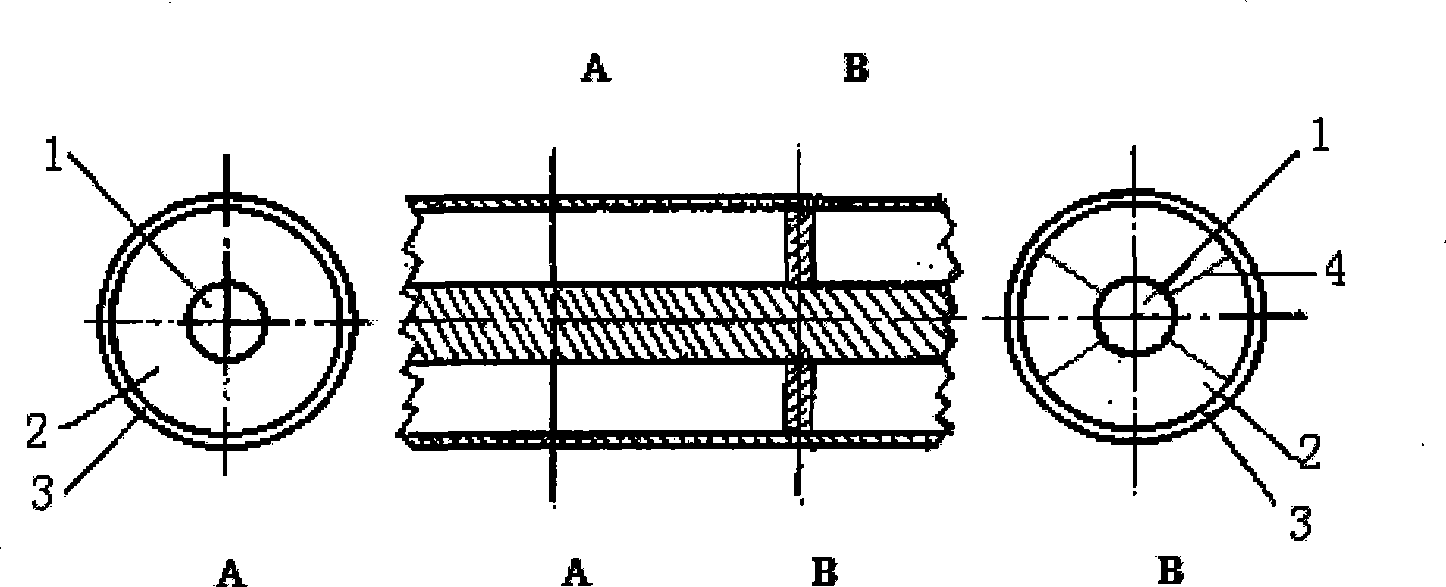

[0026] Segmented Assembly

[0027] A steel pipe, an aluminum pipe or an aluminum-plastic composite pipe is used as the outer sealing pipe 3, and the former two are coated with an anti-corrosion coating. The outer sealing tube 3 is connected in the following ways: 1. Mechanically detachable sealing method; 2. Welding method, which can be brazing, resistance welding, laser welding and other methods.

[0028] Conductive core 1 is aluminum or copper rod, bar, adopts screw connection, also can crimp with sleeve at connection. Teflon solid insulating support 4 is used between the conductive core 1 and the outer sealing tube 3 .

Embodiment 2

[0030] Continuous winding type

[0031] The outer sealing pipe 3 is welded longitudinally by steel or aluminum strips, rolled into corrugations, and coated with an anti-corrosion coating. The conductive core 1 is an aluminum or copper stranded wire, and is supported by ceramic solid insulation 4 .

Embodiment 3

[0033] Cable accessories

[0034] Rigid vacuum cables have only cable terminals and no intermediate connectors; for coiled cables, there are terminals and intermediate connectors. Both the terminal head and the intermediate connector are insulated by ceramics, and after the surface is metallized, it is welded with the conductive core and the metal shell to ensure vacuum sealing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com