Colour superfine polyester-nylon complex fiber and its processing method

A composite fiber and processing method technology, applied in fiber treatment, fiber mixing, melt spinning, etc., can solve problems such as environmental pollution, health hazards, a large amount of industrial waste gas and sewage, and achieve reasonable selection of process conditions and avoid environmental pollution , the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

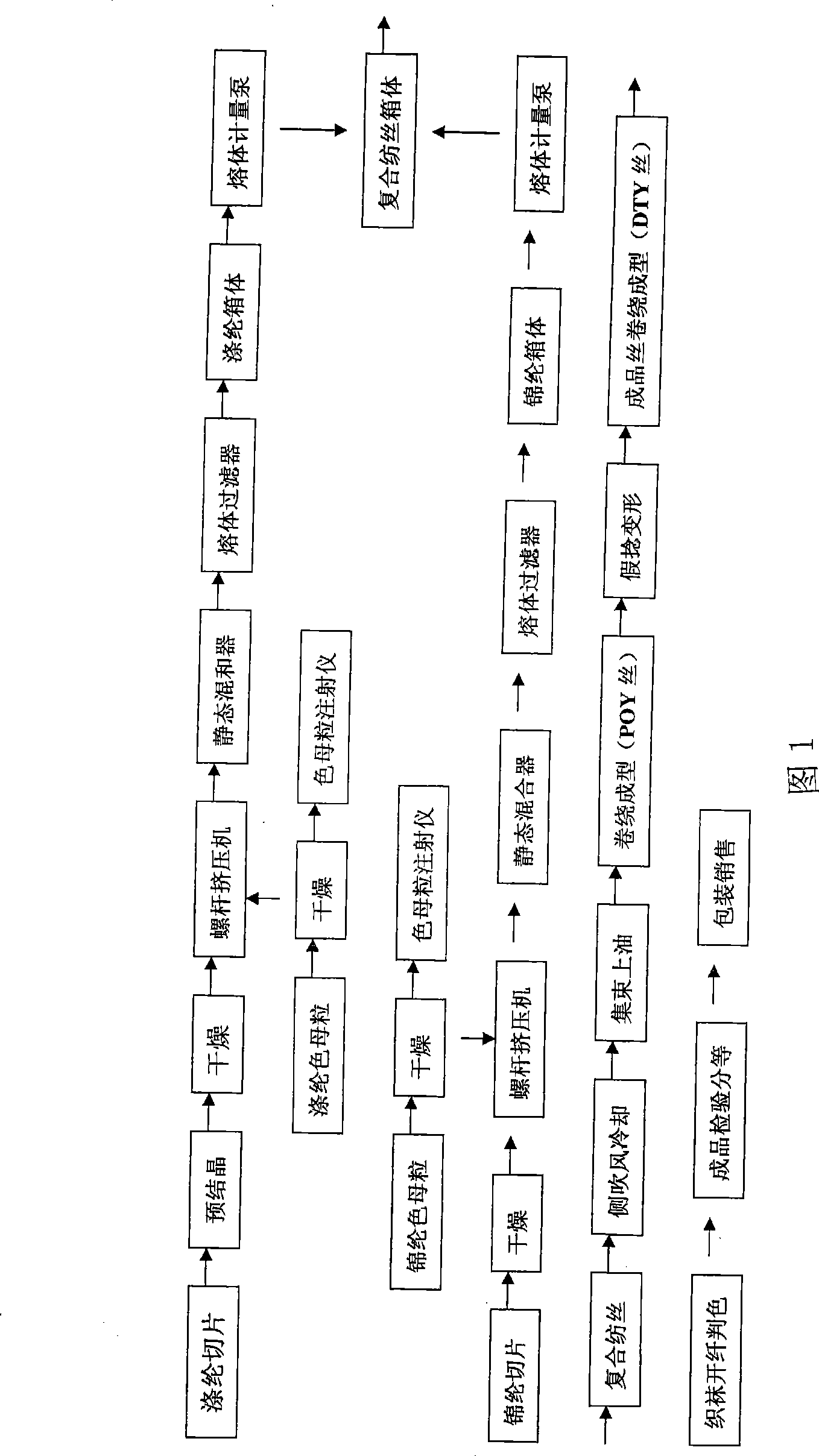

[0028] According to the technological process shown in Figure 1, the processed product specification: goose-yellow superfine polyester-nylon composite fiber with a final linear density of 83dtex / 72f×16.

[0029] A) Ingredients, according to the weight ratio, take 63.7 parts of polyester chips, namely polyester chips (PET), 34.3 parts of polyamide 6 (PA-6), 1.7 parts of goose yellow polyester masterbatch and goose yellow nylon masterbatch 0.7 part, obtain the raw material to be dried, wherein: goose yellow polyester color masterbatch and goose yellow nylon color masterbatch can be purchased by the market, such as preferably but not limited to selecting to be produced and sold by Dalian Crystal Color Masterbatch Co., Ltd., Dalian City, Liaoning Province, China Goose yellow polyester masterbatch and goose yellow nylon masterbatch;

[0030] B) dry, the four kinds of raw materials to be dried by step A) obtained polyester chips, nylon chips, goose yellow polyester color masterbatch...

Embodiment 2

[0043] According to the technological process shown in Fig. 1, the processed product specification: the final linear density is 178dtex / 72f×16 upper cyan superfine polyester-nylon composite fiber.

[0044] A) Ingredients, respectively weigh 76.8 parts of polyester chips, i.e. polyester chips (PET), 18.8 parts of nylon chips, i.e. polyamide 6 (PA-6), 3.2 parts of cyan polyester masterbatch and cyan nylon color by weight. 1.2 parts of masterbatch, obtain raw material to be dried, wherein: upper cyan polyester color masterbatch and upper cyan nylon color masterbatch all can be purchased by the market, for example preferably but not limitedly select for use by China Dalian City, Liaoning Province Dalian Crystal Color Masterbatch Co., Ltd. The company produces and sells the upper cyan polyester masterbatch and the upper cyan nylon masterbatch;

[0045] B) drying, the polyester chips obtained in step A), nylon chips, the upper cyan polyester masterbatch and the upper cyan nylon mast...

Embodiment 3

[0058] According to the technological process shown in Figure 1, the processed product specification: the final linear density is 356dtex / 144f×16 black superfine polyester-nylon composite fiber.

[0059] A) Ingredients, according to the weight ratio, take 81 parts of polyester chips, that is, polyester chips (PET), 15.475 parts of nylon chips, that is, polyamide 6 (PA-6), 3 parts of black polyester color masterbatch and black nylon color masterbatch 0.525 part, obtain raw material to be dried, wherein: black polyester color masterbatch and black nylon color masterbatch all can be bought by the market, for example preferably but not limitedly select and be produced and sold by Dalian Crystal Color Masterbatch Co., Ltd., Dalian City, Liaoning Province, China black polyester masterbatch and black nylon masterbatch;

[0060]B) dry, by step A) obtained polyester chip, polyamide fiber chip, black polyester color masterbatch and black nylon color masterbatch these four kinds of raw m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com