Sacrificial anode and protective cathode-pumping rod anti-corrosive apparatus

A technology of sacrificial anode protection and sacrificial anode, which is applied in the direction of drill pipe, drilling equipment, earthwork drilling, etc., can solve the problems of short protection period, waste of metal raw material resources, and shortened service life, so as to reduce manufacturing costs and eliminate various Accident-like, structurally simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

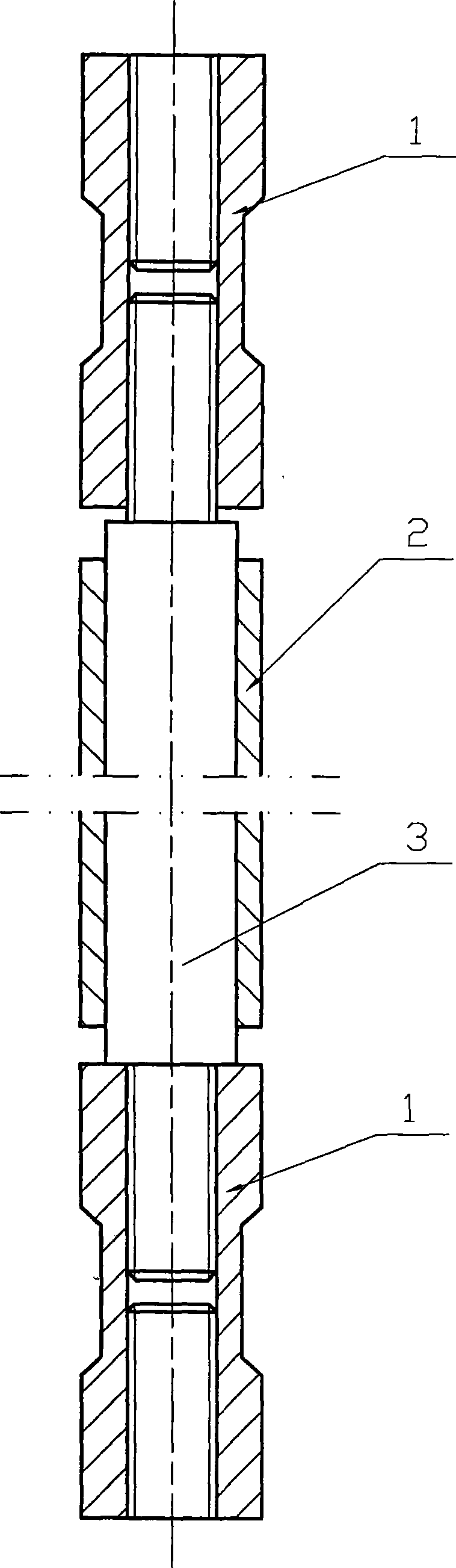

[0010] exist figure 1 Among them, the sucker rod sub-joint 3 is threadedly connected with the upper coupling 1, the anode 2 is cast on the sucker rod sub-joint 3, and the lower end of the sucker rod sub-joint is threaded with the lower coupling 1.

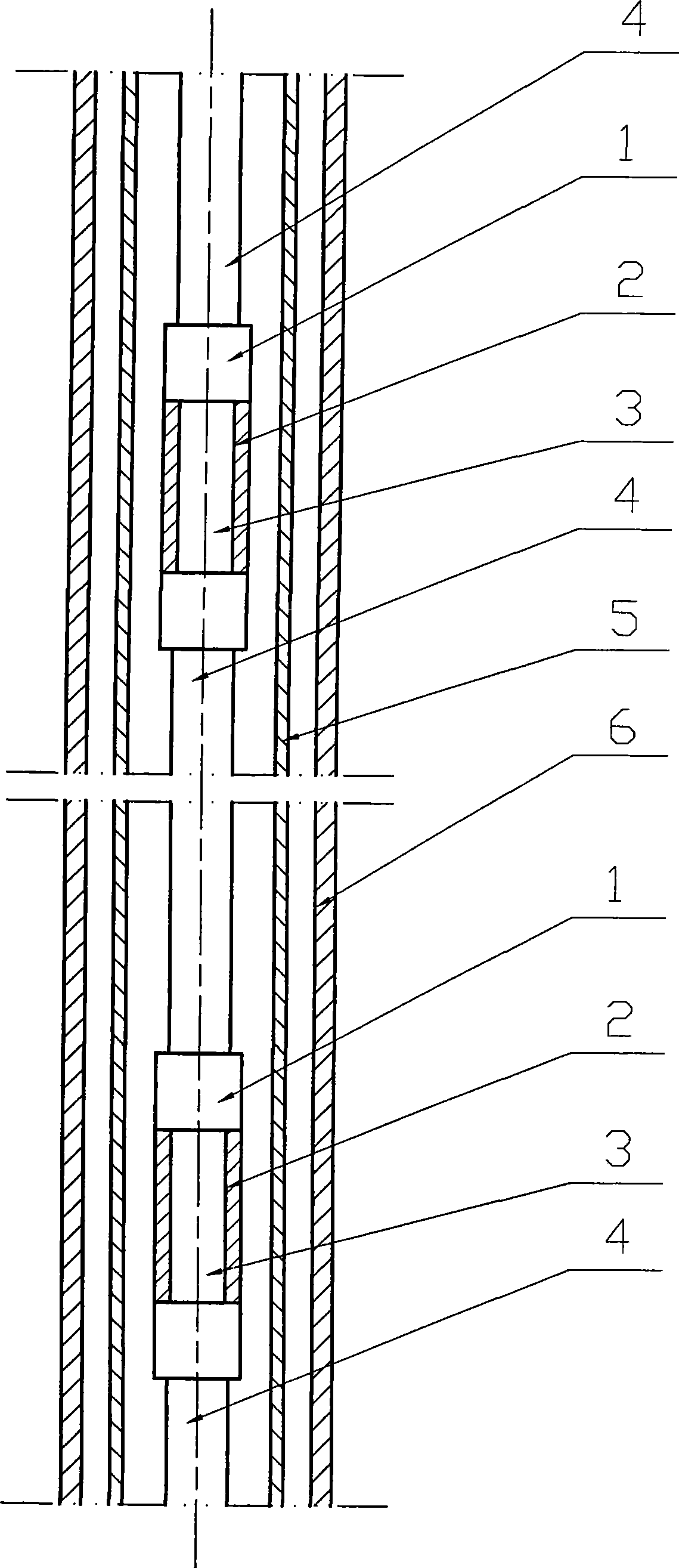

[0011] exist figure 2 In the shown embodiment, the sucker rod 4 is threaded with the coupling 1, the anode 2 and the sucker rod nipple 3 are casted together, the lower end of the sucker rod nipple is threaded with the lower collar 1, and the lower end of the lower collar is connected with the pumping rod Oil rod threaded connection. According to calculation and experience, the natural potential formed by the sucker rod anode can protect the sucker rod string up and down 50 meters. Therefore, when installing the sucker rod anode, install a set every 60-80 meters, and calculate the required installation according to the well depth Several groups, and then connect the sucker rod anode to the sucker rod column in series during the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com