End milling tool

A technology of end mills and tool holders, applied in the field of end mills, can solve problems such as high cost and environmental pollution, and achieve the effects of reducing processing costs, preventing environmental pollution, and inhibiting chip clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

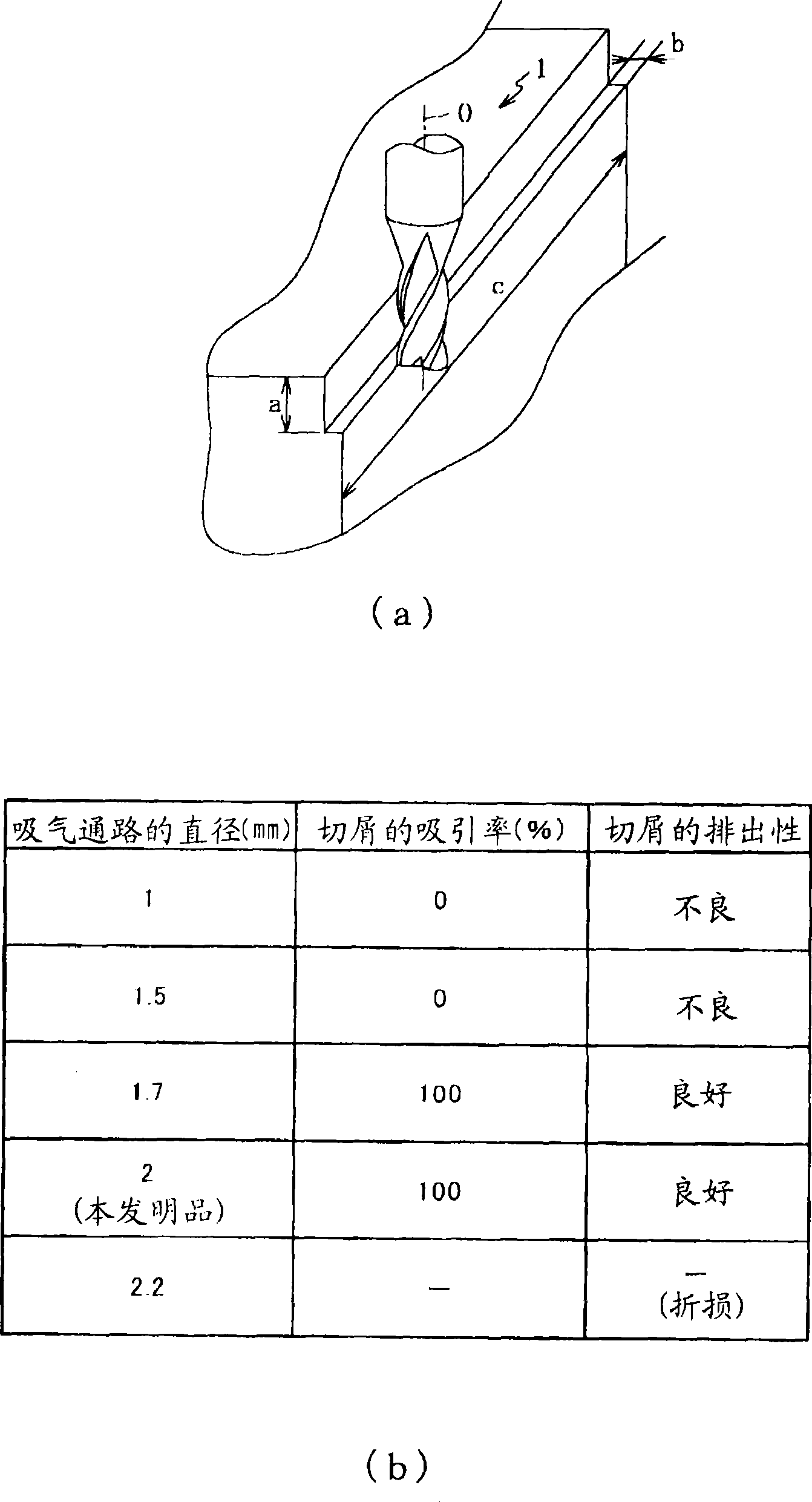

Examples

Embodiment Construction

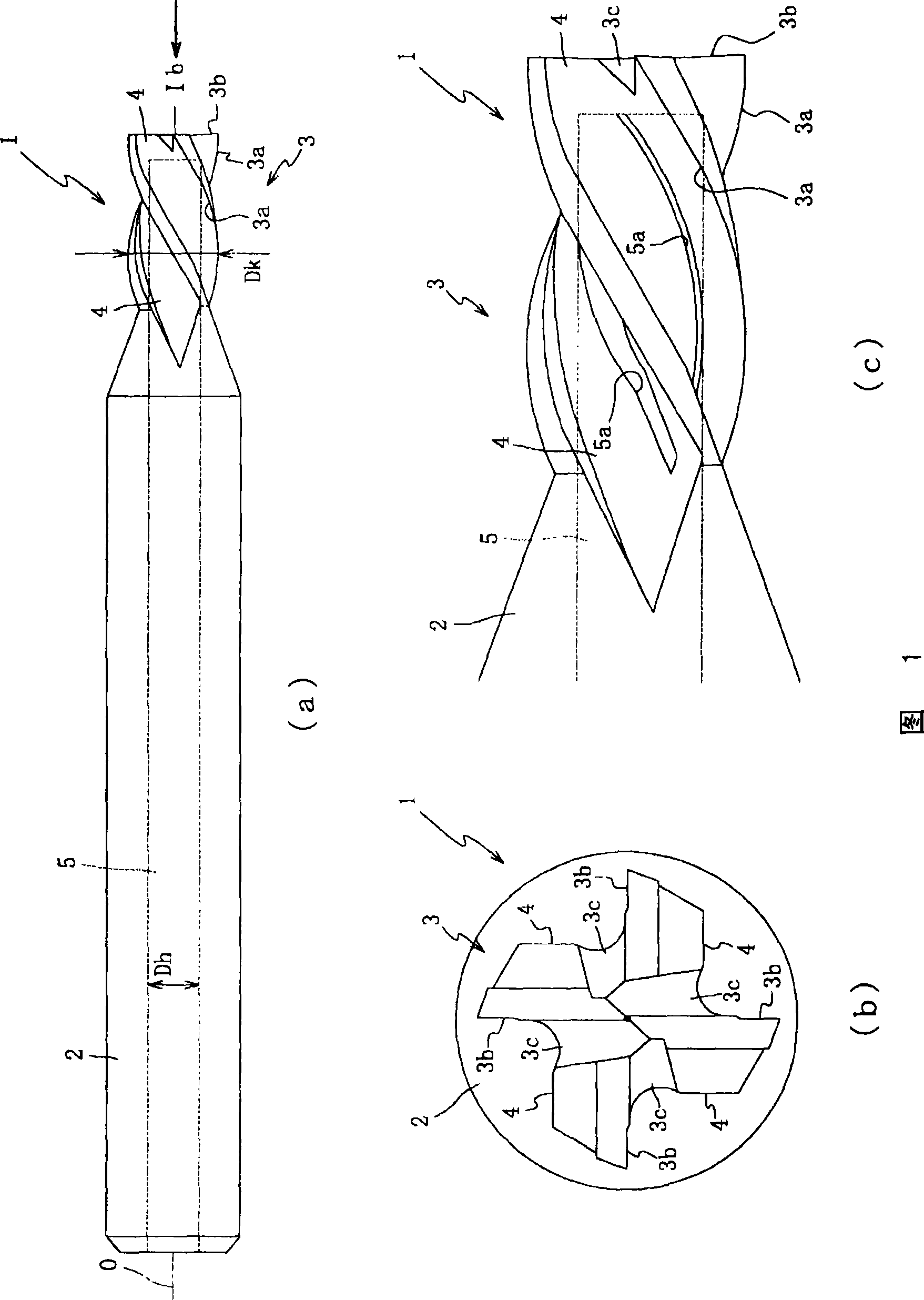

[0043] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings. First, an end mill 1 according to an embodiment of the present invention will be described with reference to FIG. 1 . Fig. 1 (a) is the front view of end mill 1, Fig. 1 (b) is the side view of end mill 1 observed from the direction of arrow 1b of Fig. 1 (a), Fig. 1 (c) is the main body part 3 Zoom in on the partial enlarged view of the obtained end mill 1.

[0044] The end mill 1 is a tool for cutting a workpiece (not shown) using a rotational force transmitted from a processing machine (not shown), and as shown in FIG. The cemented carbide obtained by pressing and sintering constitutes an integral square end mill, which mainly includes a handle 2 and a main body 3 connected to the handle 2 . However, the end mill 1 is not limited to cemented carbide, and may be made of high-speed tool steel.

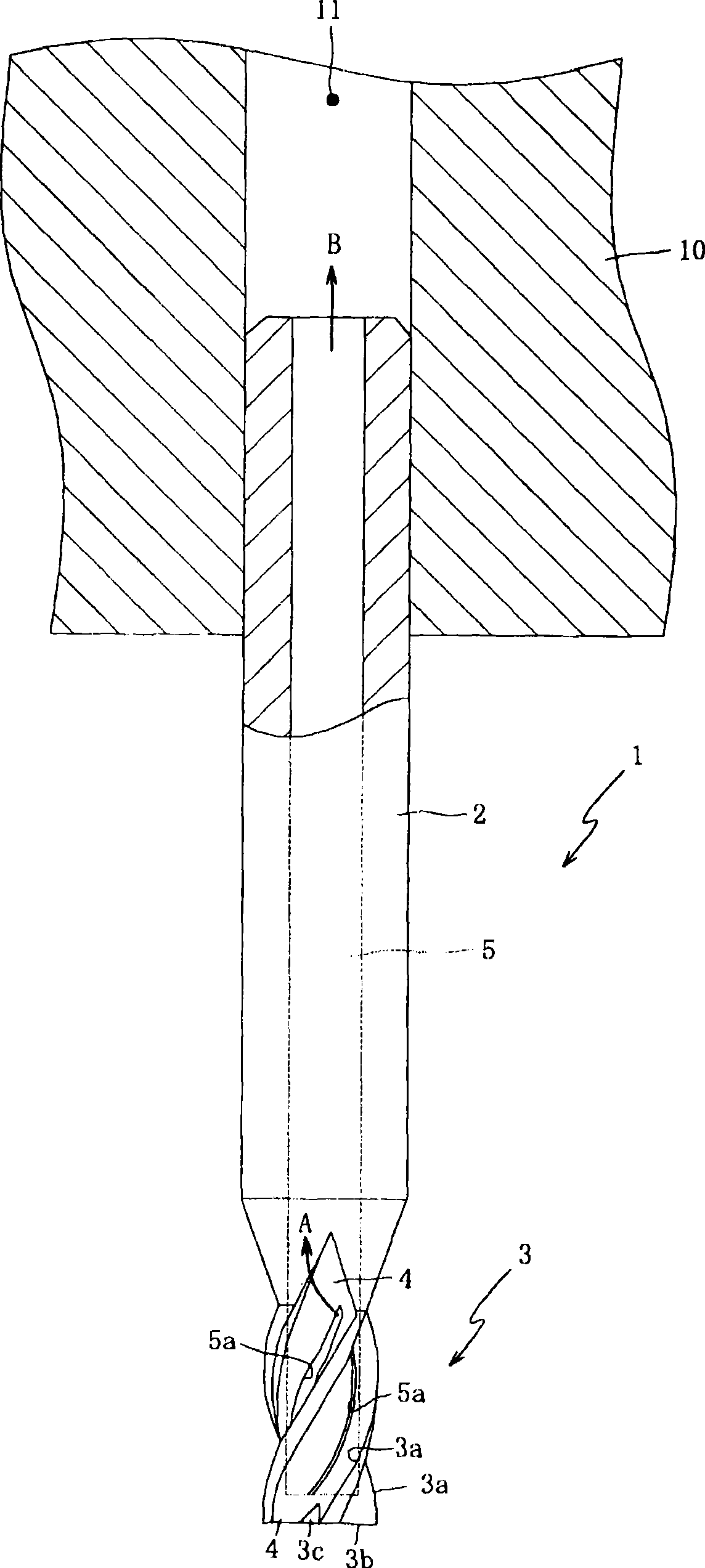

[0045] Knife handle 2 is via knife rest 10 (referring to figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com