Electroplating washing water zero discharge method

A technology for cleaning water and zero discharge, applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of difficult implementation, high cost, shortened life, etc., and achieve the effect of solving the waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Such asfigure 1 As shown, add Cr by weight to the chromium-containing cleaning water 6+ 3.5 times the sodium metabisulfite, the Cr 6+ reduced to Cr 3+ ; Then use a laminated filter to filter to remove impurities with larger particles; then use a PP filter element filter to remove tiny particles above 5μ; then pressurize with a high-pressure pump to make the pressure greater than the osmotic pressure and enter the reverse osmosis Treatment, reverse osmosis treatment uses a neutral anti-pollution reverse osmosis membrane to remove metal ions in it to produce RO water; finally adjust the pH value of RO water to 6.8 with sodium hydroxide, which is reuse water. After testing, its conductivity is 125μ, and the desalination rate reaches 95%. This reused water is used in the electroplating cleaning process and can replace clean tap water.

[0039] The concentrated water produced by the reverse osmosis treatment is neutralized with sodium hydroxide to adjust its acidity to ne...

Embodiment 2

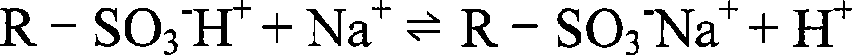

[0041] A factory discharges 40 tons of nickel-containing waste water every day. The processing of this factory is mainly hanging plating, and the nickel content in the waste water is 30ppm-80ppm. After preprocessing, such as figure 2 As shown, select a bag filter with a pore size of 50 μm and a security filter with a pore size of 5 μm to filter, then perform reverse osmosis treatment, and use two-stage concentration. Add 30% soda ash solution to the concentrated solution, stir while adding, and adjust to a pH value of 8 to 8.5. At this time, nickel is completely precipitated in the form of nickel carbonate; it is precipitated through an inclined tube sedimentation tank, and the supernatant is passed through an anion resin exchange column and Return to RO system after cation resin exchange column. Anion exchange resin and cation exchange resin are regenerated with 8% sodium hydroxide and 8% hydrochloric acid respectively after running for a period of time to reach saturation....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com