Positive electrode for non-aqueous electrolyte secondary battery and non-aqueous electrolyte secondary battery using the same

A non-aqueous electrolyte, secondary battery technology, applied in secondary batteries, battery electrodes, active material electrodes, etc., can solve problems such as the reduction of active material quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

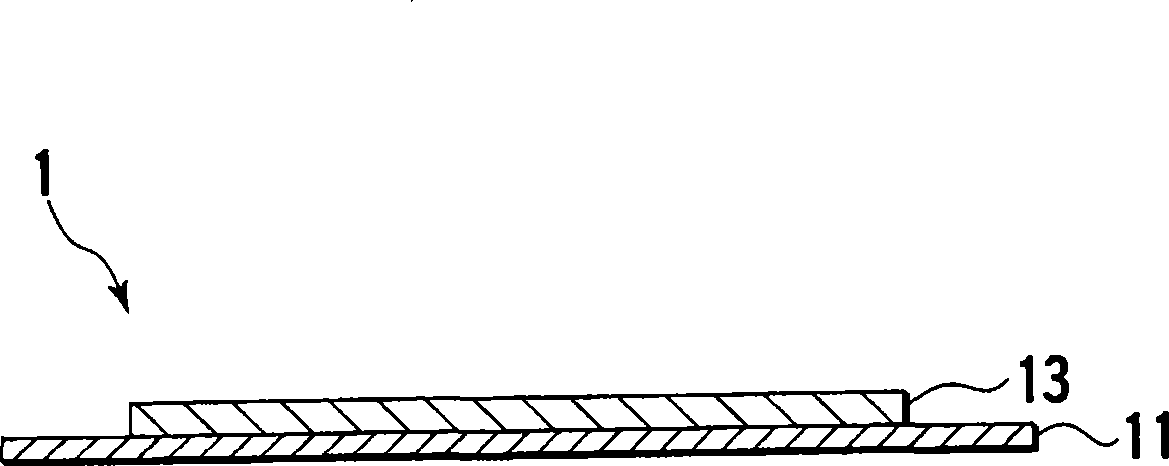

[0020] A first embodiment of the present invention is a positive electrode of a nonaqueous electrolyte secondary battery, which is constituted by forming a positive electrode active material layer on a current collector. Moreover, the positive electrode active material layer comprises spinel lithium manganate as the positive electrode active material, and a composite oxide represented by the following formula (1):

[0021] LiCo v Ni x mn y m z o 2 (1)

[0022] In the formula, v+x+y+z=1, M is any one selected from aluminum (Al), gallium (Ga) and indium (In), 0≤v≤0.5, 0.3≤x<1, 0≤ y≤0.5, and 0≤z≤0.1. Furthermore, the positive electrode active material layer is characterized in that the average particle diameter of the composite oxide is larger than the average particle diameter of the spinel-type lithium manganate.

[0023] Despite excellent capacity characteristics, complex oxides have an inherent problem of poor thermal stability. However, by adjusting the average p...

no. 2 approach

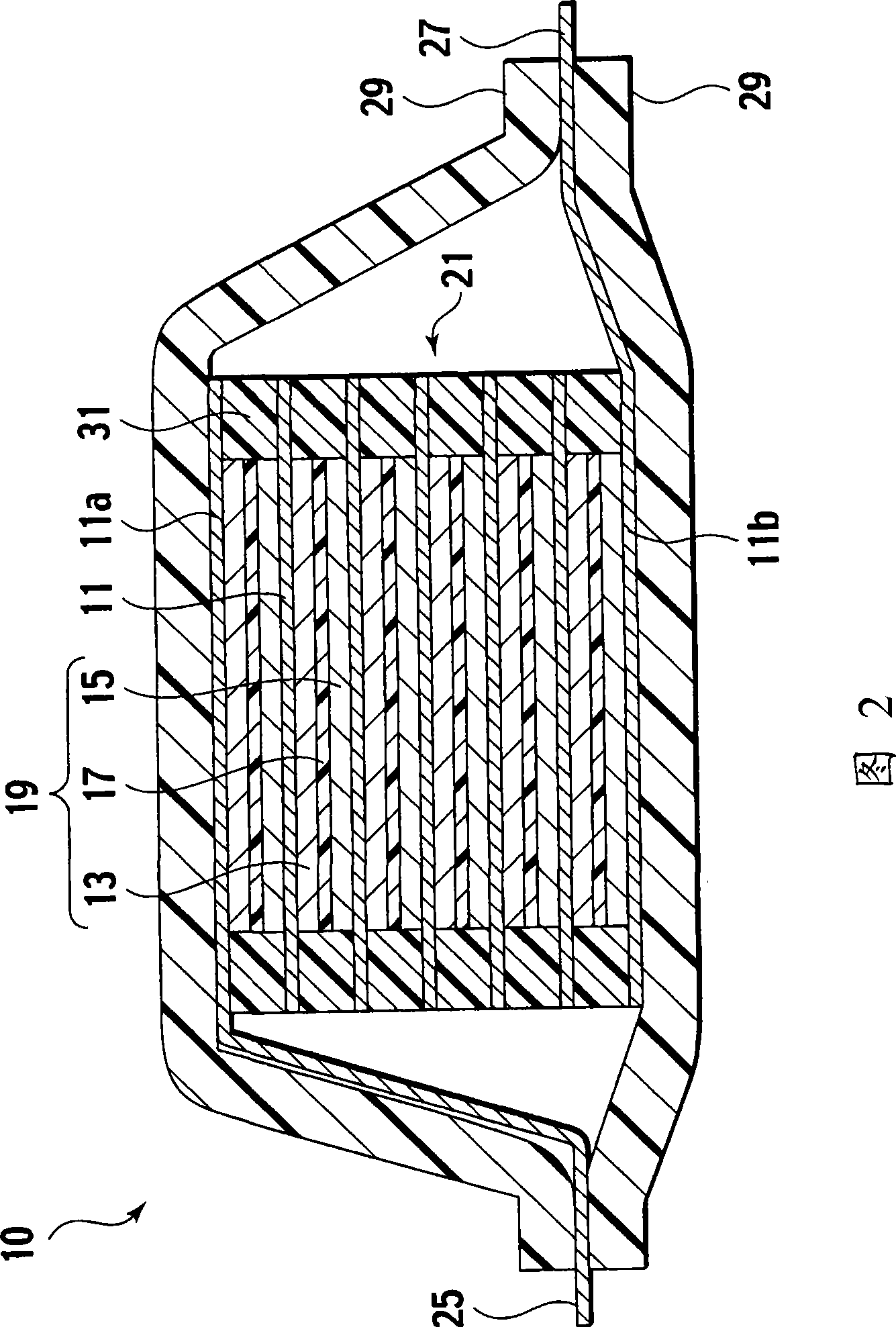

[0078] In the second embodiment, a nonaqueous electrolyte secondary battery is constituted using the positive electrode of the nonaqueous electrolyte secondary battery of the above-mentioned first embodiment. Specifically, the second embodiment of the present invention is a non-aqueous electrolyte secondary battery comprising at least one single cell layer formed by sequentially stacking a positive electrode, a dielectric layer, and a negative electrode, characterized in that, using the non-aqueous electrolyte according to the present invention The positive electrode of the aqueous electrolyte secondary battery was used as the above-mentioned positive electrode.

[0079] A nonaqueous electrolyte secondary battery including the positive electrode of the nonaqueous electrolyte secondary battery of the present invention as at least one electrode belongs to the technical scope of the present invention. However, it is preferable that all electrodes constituting the nonaqueous elect...

no. 3 approach

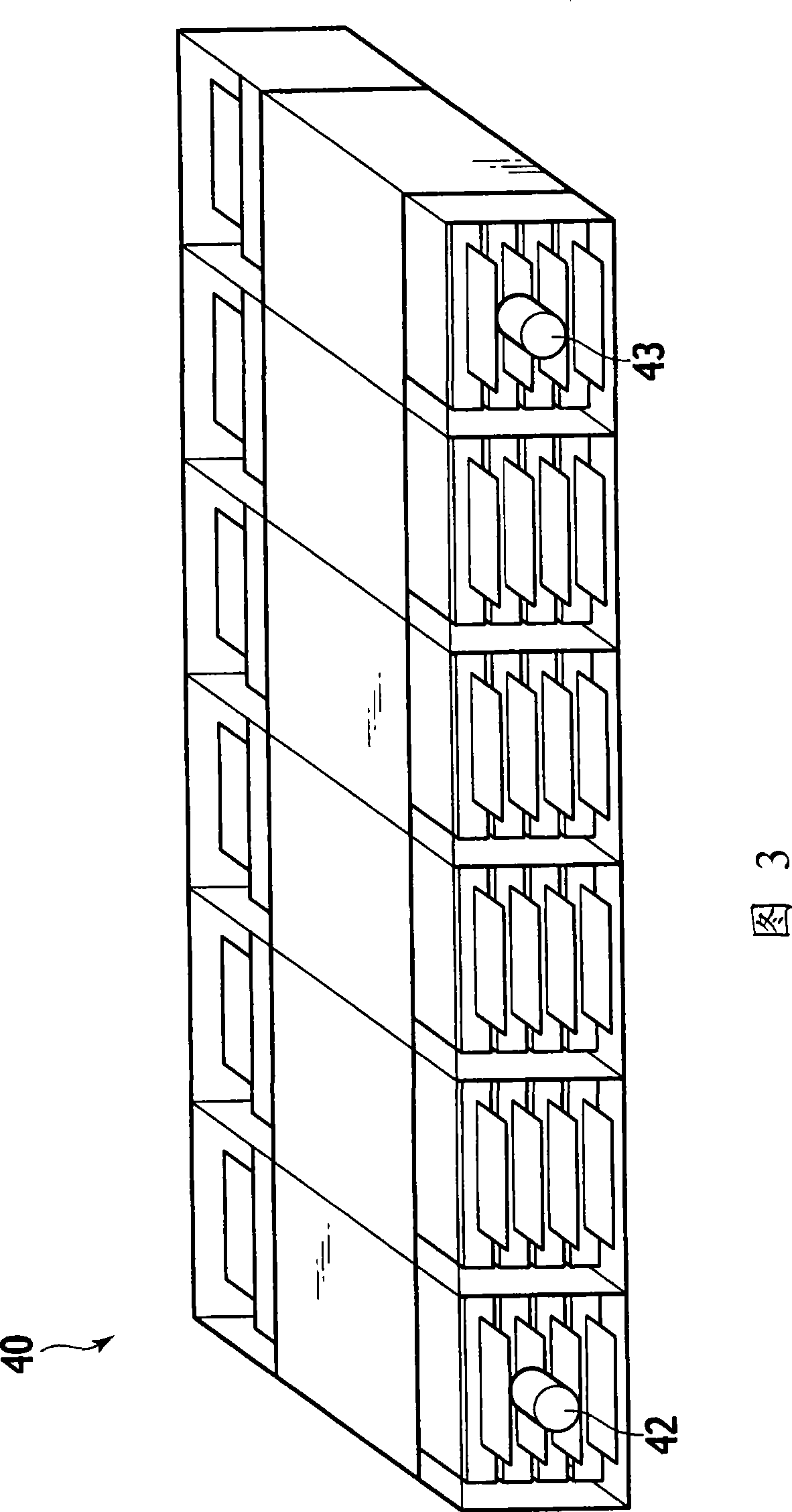

[0103] In the third embodiment, an assembled battery is constructed by connecting a plurality of bipolar batteries of the above-mentioned second embodiment in parallel and / or in series.

[0104] Fig. 3 is a perspective view of the assembled battery of the present embodiment.

[0105] As shown in FIG. 3, an assembled battery 40 is constructed by connecting a plurality of bipolar batteries described in the above-mentioned second embodiment to each other. Each bipolar battery 10 is connected by connecting its positive terminal 25 and negative terminal 27 to each other using bus bars. On one side of the assembled battery 40 , electrode terminals 42 and 43 are provided as electrodes of the assembled battery 40 as a whole.

[0106] There is no specific limitation on the connection method when the plurality of bipolar batteries 10 constituting the assembled battery 40 are connected to each other, and known methods can be appropriately employed. For example, welding methods such as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Grain diameter | aaaaa | aaaaa |

| Average particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com