Method for preparing modification forming magnalium hydrotalcite and application

A magnesium-aluminum hydrotalcite and modification technology, which is applied to the preparation and application field of modified magnesium-aluminum hydrotalcite, can solve the problems of poor treatment effect of inorganic pollutants such as phosphorus and nitrogen, and solve the problem of poor treatment effect of phosphorus and nitrogen. Excellent, strong adsorption effect, easy separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] Preparation method of modified magnesium aluminum hydrotalcite

[0010] 3000mol of MgSO 4 and 500mol of Al 2 (SO 4 ) 3 Prepared into mixed brine solution (the total amount is 4.0m 3 ), the NaOH of 5000mol and the Na of 10000mol 2 CO 3 Mixed alkali aqueous solution (the total amount is 4.0m 3 ), put the two aqueous solutions into the fully mixed jet reactor through the pipeline, and react under the condition of controlling the pH value at 8-9 to obtain a milky white slurry, which is directly added to the aging tank and kept stirring After the reaction is complete, seal the aging tank, heat to 130°C, and keep the temperature at (130±5)°C, crystallize for 24 hours, then add the crystallized material to a plate and frame filter press, wash with tap water until the filtrate At this time, the pH value of the filtrate was 7. Finally, the washed substance was spray-dried, and the inlet and outlet temperatures of the spray drying tower were kept at 300°C and 120°C respect...

Embodiment 2

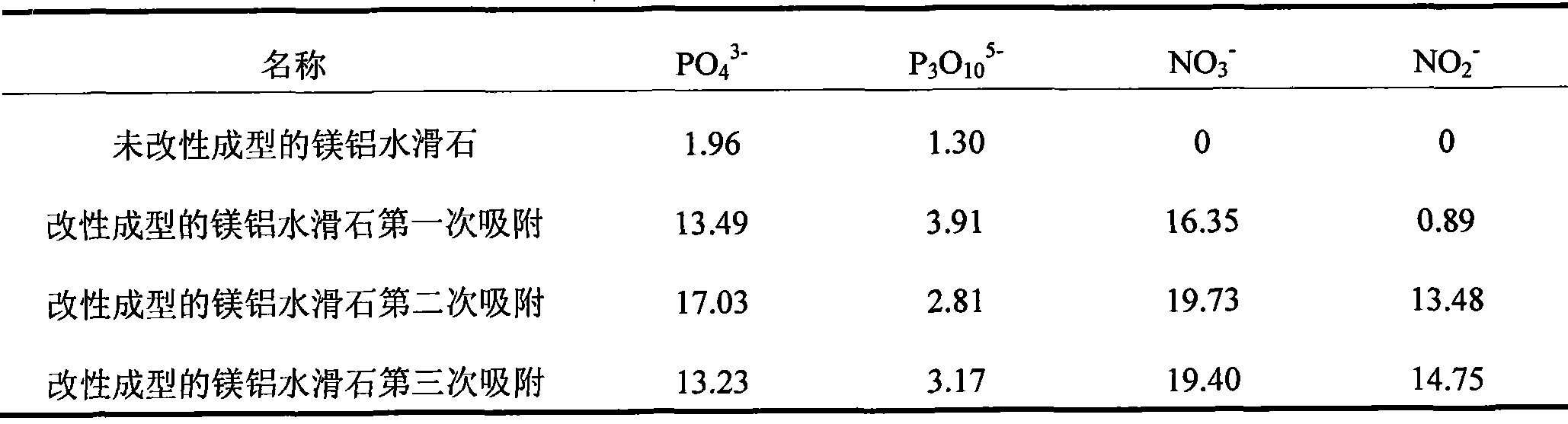

[0013] Removal of PO in aqueous solution by unmodified and modified magnesium aluminum hydrotalcites 4 3- ,P 3 o 10 5- , NO 3 - , NO 2 -

[0014] The unmodified and modified magnesium aluminum hydrotalcite prepared in Example 1 were respectively loaded into the adsorption column according to the diameter-to-height ratio of 1.1:10, and the PO in the aqueous solution was adsorbed and removed respectively. 4 3- ,P 3 o 10 5- , NO 3 - , NO 2 - , their respective initial concentrations are calculated in terms of phosphorus or nitrogen, which are 50 mg / L, and the flow rate of the aqueous solution to pass through the adsorption column is controlled to be 5 mL / min. According to the first-level standard of the national comprehensive sewage discharge standard, the first-level standard of the national drinking water source water quality and the groundwater quality standard, the concentration of phosphorus in the aqueous solution after adsorption is 0.5mg / L, the concentrati...

Embodiment 3

[0019] Simultaneous removal of PO in aqueous solution by modified magnesium aluminum hydrotalcite 4 3- ,P 3 o 10 5- , NO 3 - , NO 2 - The modified magnesium aluminum hydrotalcite obtained in Example 1 is loaded into the adsorption column according to the diameter-to-height ratio of 1.1:15, and the PO in the aqueous solution is removed simultaneously. 4 3- ,P 3 o 10 5- , NO 3 - , NO 2 - , and their respective initial concentrations are calculated as phosphorus or nitrogen, both are 25mg / L, and the flow rate of the aqueous solution through the adsorption column is controlled to be 5mL / min. The breakthrough concentration of each ion is as described in Example 2, to obtain PO 4 3- ,P 3 o 10 5- , NO 2 - The breakthrough time is 95, 75, 75min, while NO 3 -Has not penetrated within 300min. It can be seen that the modified magnesium aluminum hydrotalcite can remove PO in the aqueous solution at the same time. 4 3- ,P 3 o 10 5- , NO 3 - , NO 2 - . Due...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com