Numerical control polishing machine for optical elements

A technology of optical components and machine tools, which is applied in the field of improvement of optical component manufacturing equipment, can solve problems such as low efficiency and difficult control of precision, and achieve the effects of ensuring high certainty, improving efficiency, and ensuring operation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

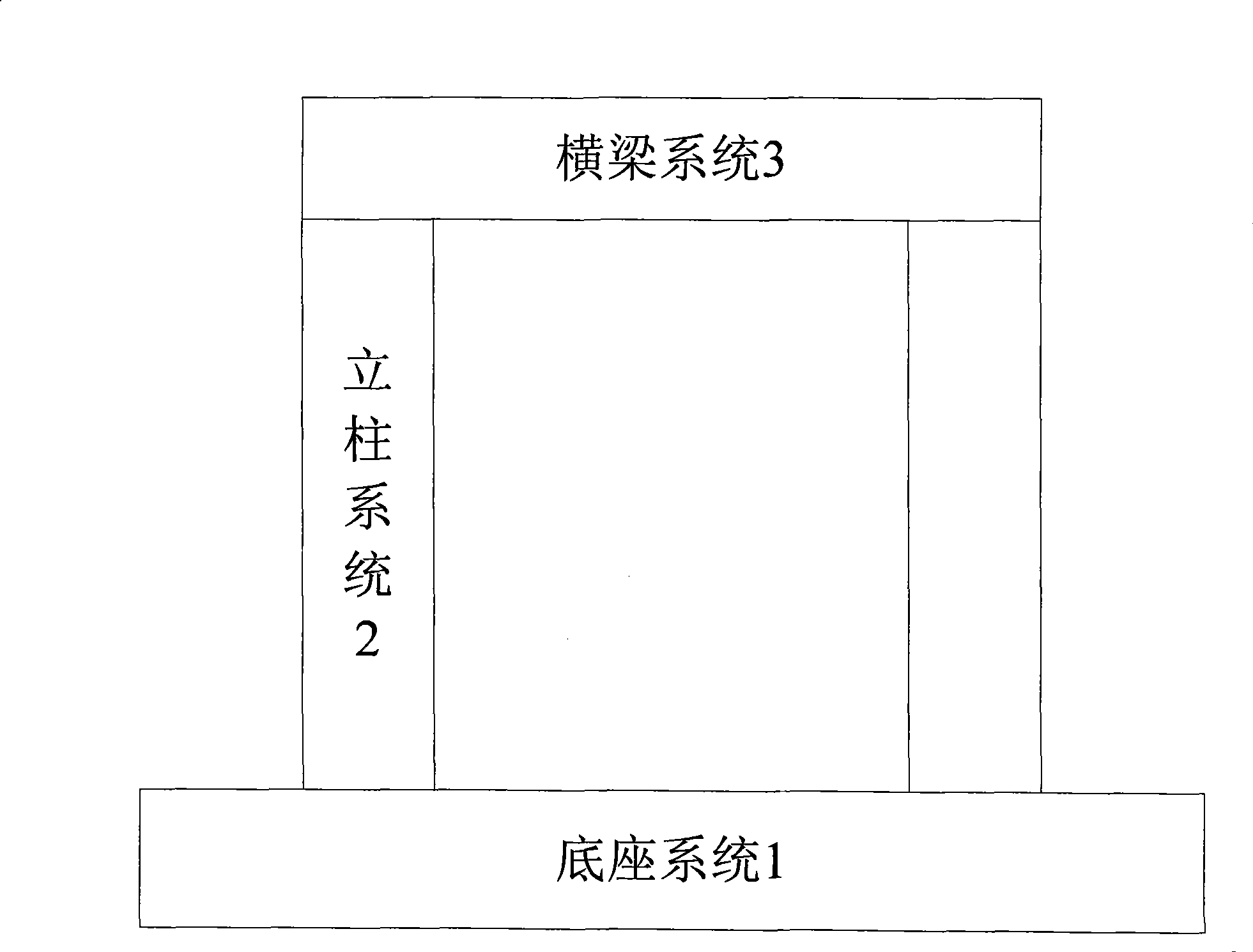

[0031] Such as figure 1 As shown, 1 is the base system, 2 is the column system, and 3 is the beam system;

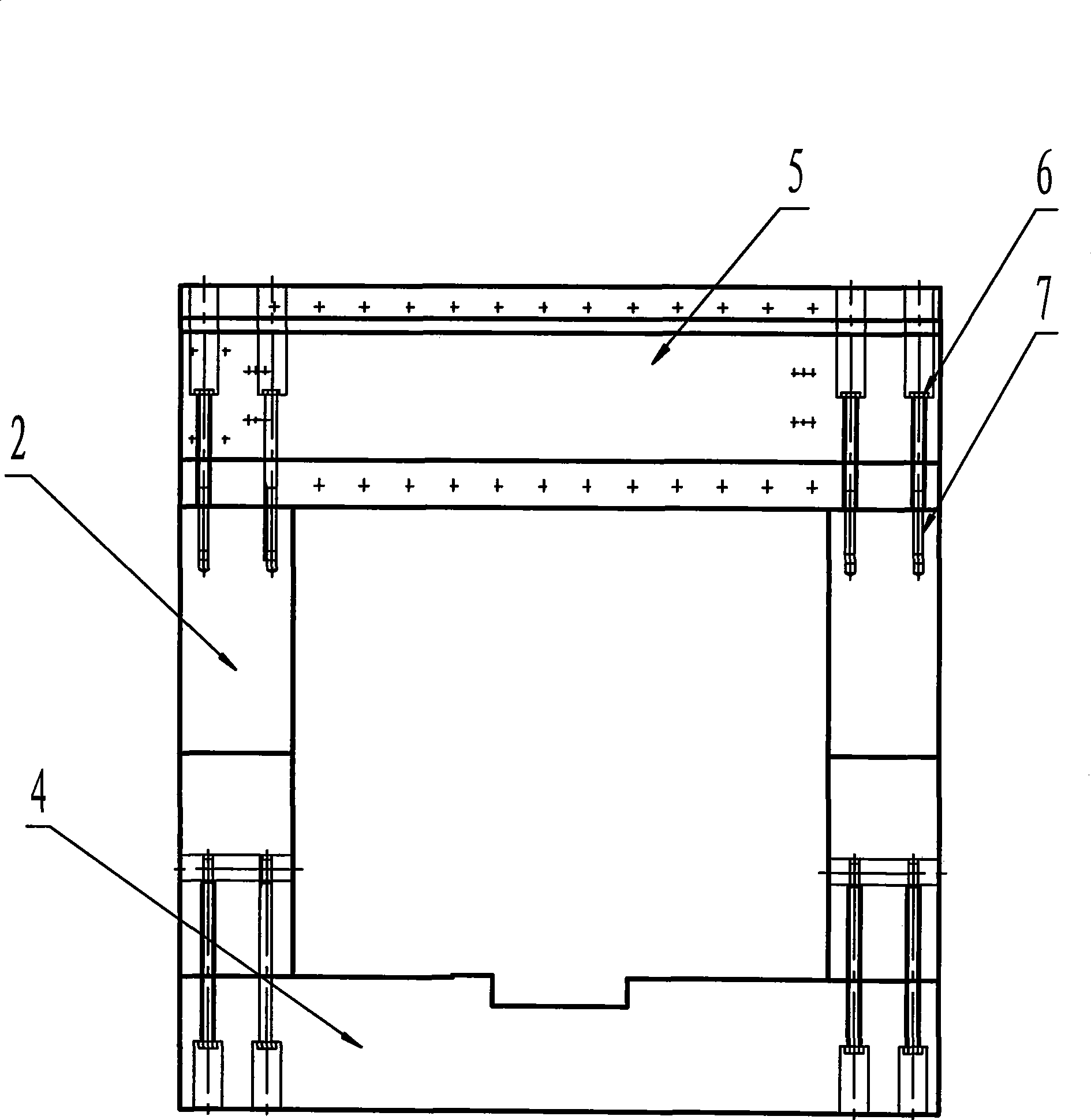

[0032] Such as figure 2 As shown, 4 is the base of the bed, 5 is the beam, 6 is the screw, and 7 is the embedded nut;

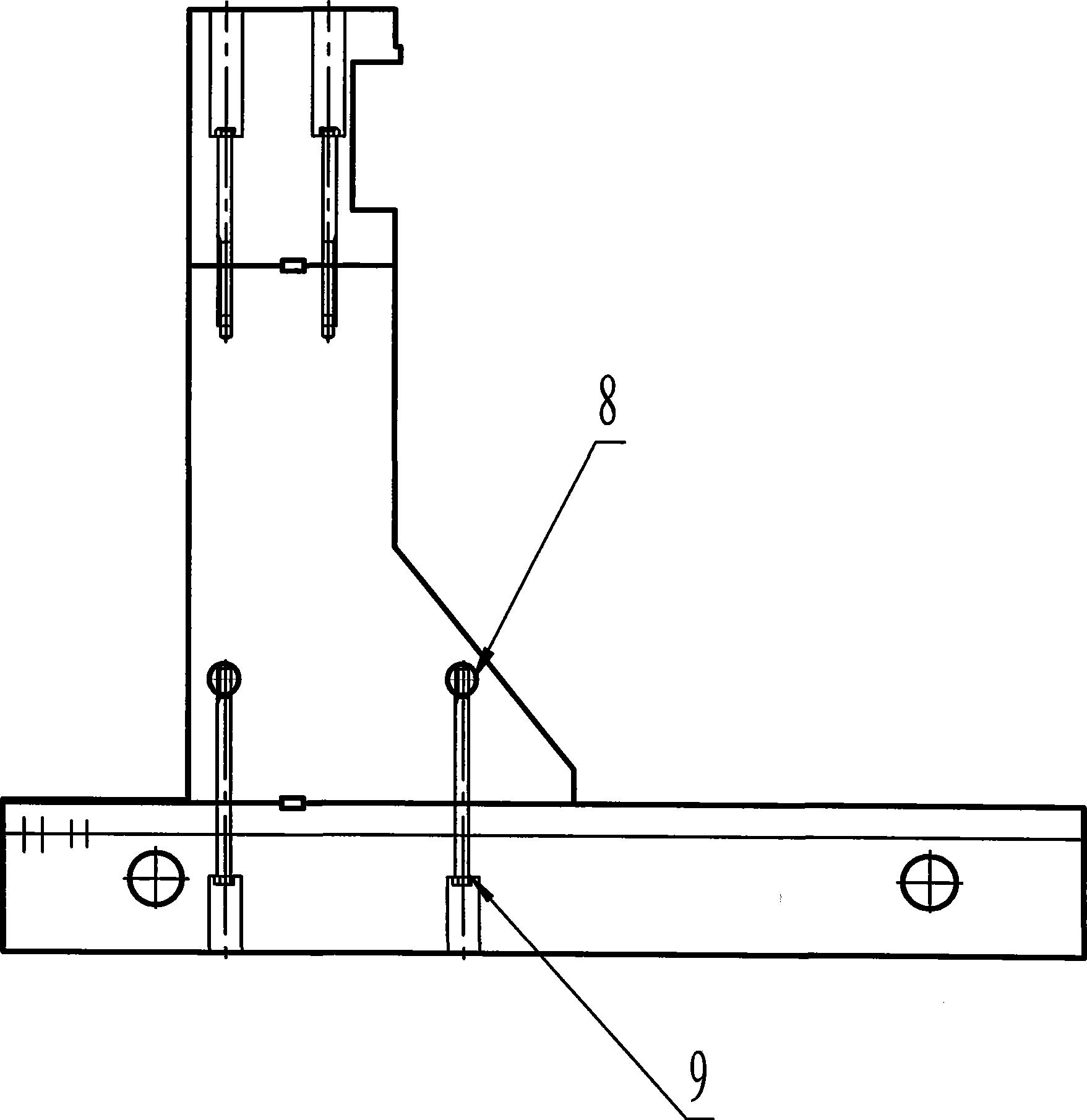

[0033] Such as image 3 As shown, 8 is the connecting nut between the column and the bed base, and 9 is the connecting bolt between the column and the bed base;

[0034] Such as Figure 4 As shown, 10 is the Z axis of the numerical control axis, 11 is the Y axis of the numerical control axis, 13 is the A axis of the numerical control axis, 15 is the power planetary polishing head, and 16 is the polishing mold;

[0035] Such as Figure 5 As shown, 12 is the CNC axis X axis, and 14 is the C axis rotary feed system;

[0036] Such as Figure 6 As shown, 17 is the X-axis double-nut preload structure, 18 is the A-axis worm gear pair, 19 is the A-axis gear pair, 20 is the A-axis servo motor, 21 is the Y-axis servo motor, and 22 is the Y-axis precision ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com