Hotchemistry heat exchanger circulating system based on re-adsorption technology

A technology of chemical temperature changer and circulation system, which is applied in the field of thermochemical temperature changer circulation system, can solve the problems of large fluctuation of working pressure and affect the temperature rise capacity of the system, and achieve the effect of reducing the fluctuation, improving the adsorption method and ensuring the temperature raising ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

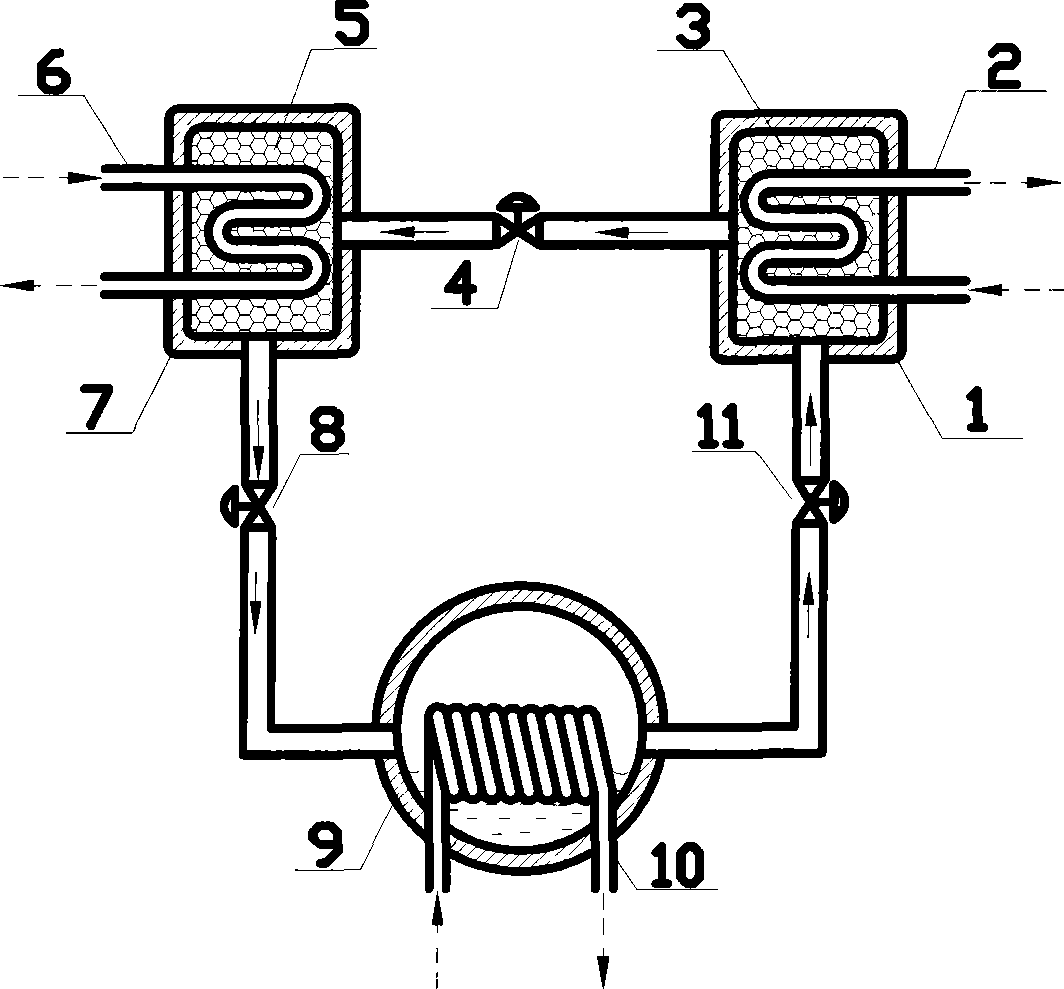

[0023] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

[0024] Such as figure 1 As shown, this embodiment includes a high temperature reactor 1, a high temperature reactor heating and cooling coil 2, a high temperature reaction chemical adsorbent 3, an intermediate regulating valve 4, a low temperature reaction chemical adsorbent 5, and a low temperature reactor heating and cooling coil 6 , low temperature reactor 7, low temperature regulating valve 8, condenser 9, condenser heat exchange coil 10, high temperature regulating valve 11.

[0025] The outlet of high temperature reactor 1 is connected to the inlet of intermedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com