Method for preparing ion polymer-metal composite material

A metal composite material, ionic polymer technology, applied in metal material coating process, liquid chemical plating, coating and other directions, can solve the problems of unstable material performance, expensive platinum salt, unsuitable for palladium metal, etc. Precious metal cost, reduced waste, effects of good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the drawings and embodiments.

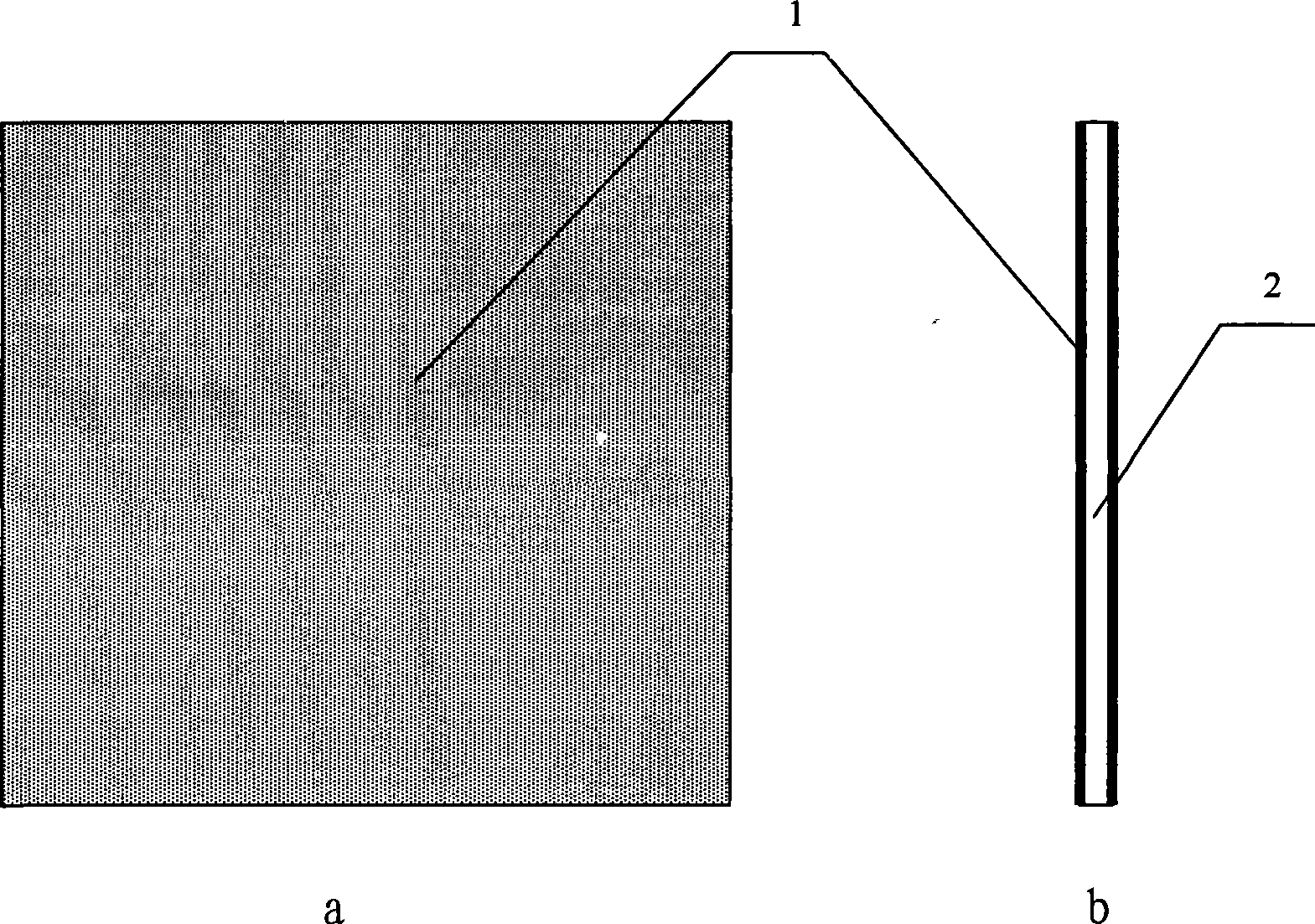

[0026] Such as figure 1 As shown, the preparation method of the present invention is illustrated by taking the preparation of an IPMC material with a size of about 5cm×5cm as an example:

[0027] 1) Pretreatment process:

[0028] The Nafion ion exchange membrane 2 is used as the base material, because it is made of a small area material, it can be roughened with sandpaper, and the surface of the Nafion membrane 2 is lightly sanded with sandpaper above 600. When polishing, try to make the surface uniformly stressed. Don't use too much force, otherwise it will cause plastic deformation. Finally, pay attention to the roughness uniformity. Observe the surface under the light that the surface becomes turbid without obvious bright spots. It can be considered that the polishing achieves a uniform effect.

[0029] Sandblasting process can also be used, then use a san...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com