Preparation of manganese series water quenching bainite steel

A bainitic steel and water quenching technology, applied in the field of alloy steel manufacturing, can solve the problems of low hardenability, high production cost of high-strength alloy steel, complex production process, etc. The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation method of the manganese series water-quenched bainite steel proposed by the present invention is firstly smelted by a conventional steelmaking process, and then produced by ingot injection or continuous casting. The weight percentage of each component in the steel is:

[0020] C: 0.05—0.42%

[0021] Mn: 1.80—3.00%

[0022] Si: 0.20—1.80%

[0023] Cr: 0—1.60%

[0024] Ti: 0—0.12%

[0025] V: 0—0.12%

[0026] Nb: 0—0.12%

[0027] N 0—0.02%

[0028] B: 0—0.01%

[0029] The remainder is Fe;

[0030] Then the above steel is forged or rolled into products at 1100°C-1250°C, water-cooled or oil-cooled to room temperature-300°C; the above-mentioned products are heated to 200-650°C, kept for 1-3 hours for tempering.

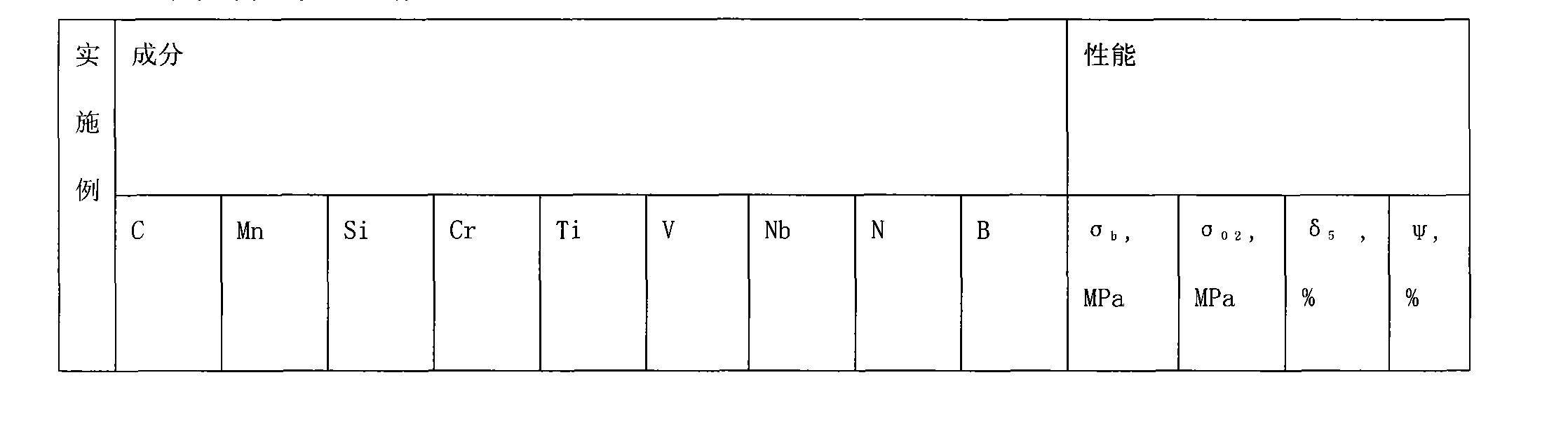

[0031] Embodiment of the present invention sees the following table:

[0032]

[0033]

Embodiment 1

[0034] The preparation method of embodiment 1 is as follows:

[0035] (1) Use a converter or an electric furnace to carry out continuous casting of conventional steelmaking processes to produce blanks.

[0036] (2) Cool the billet to 1200°C and roll it into a Φ300 bar, then oil-cool it to 200°C and then slowly cool it to room temperature.

[0037] (3) Heat the bar to 250°C, keep it warm for 2 hours, and perform tempering treatment.

Embodiment 2

[0038] The preparation method of embodiment 2 is as follows:

[0039] (1) Use a converter or an electric furnace to carry out continuous casting of conventional steelmaking processes to produce blanks.

[0040] (2) Cool the billet to 1200°C and roll it into a Φ300 bar, then oil-cool it to 200°C and then slowly cool it to room temperature.

[0041] (3) Heat the rod to 200°C, keep it warm for 2 hours, and perform tempering treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com