Method and apparatus for removing hydrogen peroxide

A technology for hydrogen peroxide removal, applied in chemical instruments and methods, separation methods, nanotechnology for materials and surface science, etc., can solve problems such as low reaction rate, low contact efficiency, and small specific surface area of catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

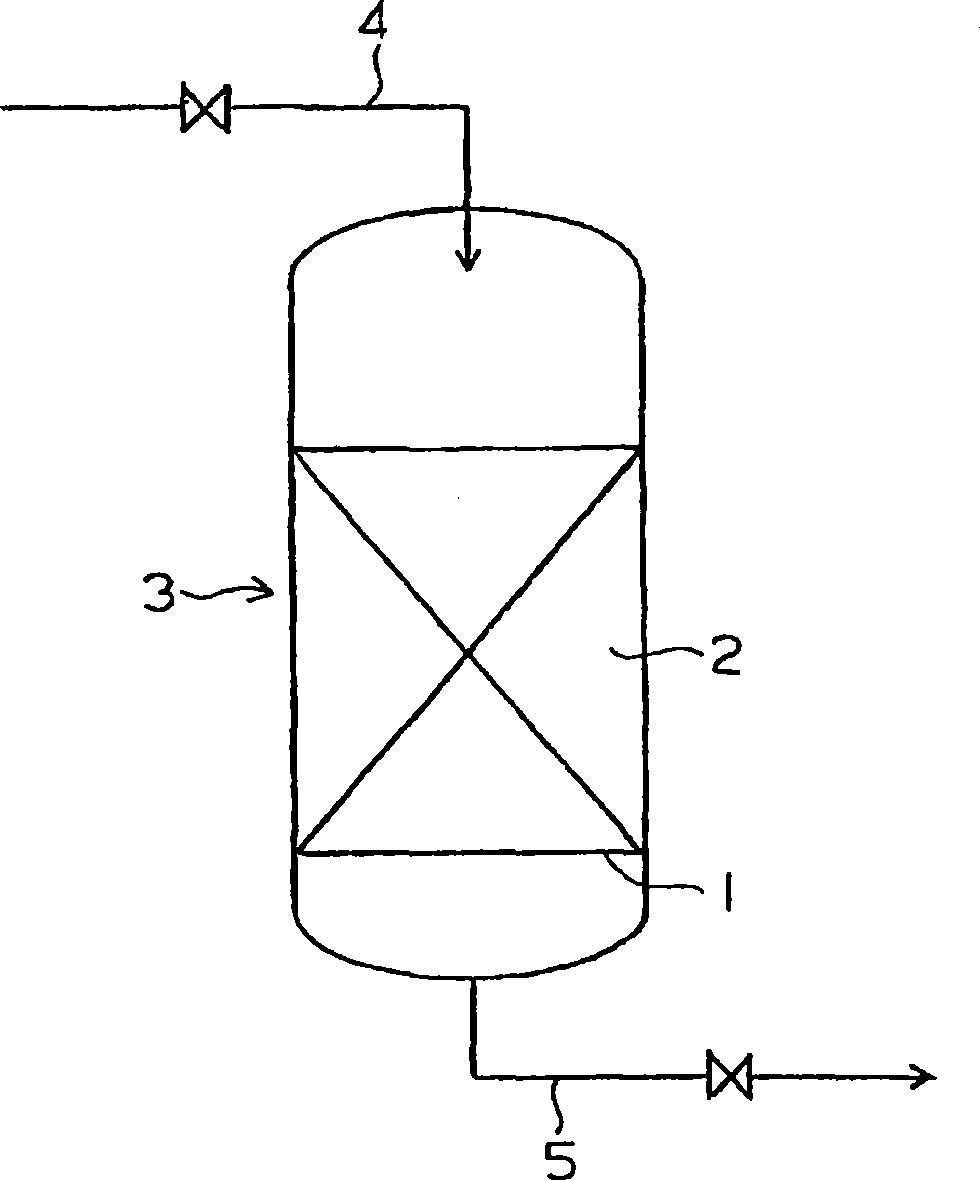

[0061] Platinum nanomicelle particles with an average diameter of 3.5nm are deposited and loaded on the gel-type strongly basic anion exchange resin, and the deposition amount is 0.07% of the weight of the carrier, and a hydrogen peroxide decomposition catalyst is prepared.

[0062] A column made of acrylic resin was filled with 100 ml of the prepared hydrogen peroxide decomposition catalyst, and at SV=1,000 h -1 Next, ultrapure water containing 29.54 ppb (by weight) hydrogen peroxide was passed through the column in a downward direction. The concentration of hydrogen peroxide in the treated water discharged from the column was 0.38 ppb by weight, and the removal rate of hydrogen peroxide was 98.7%.

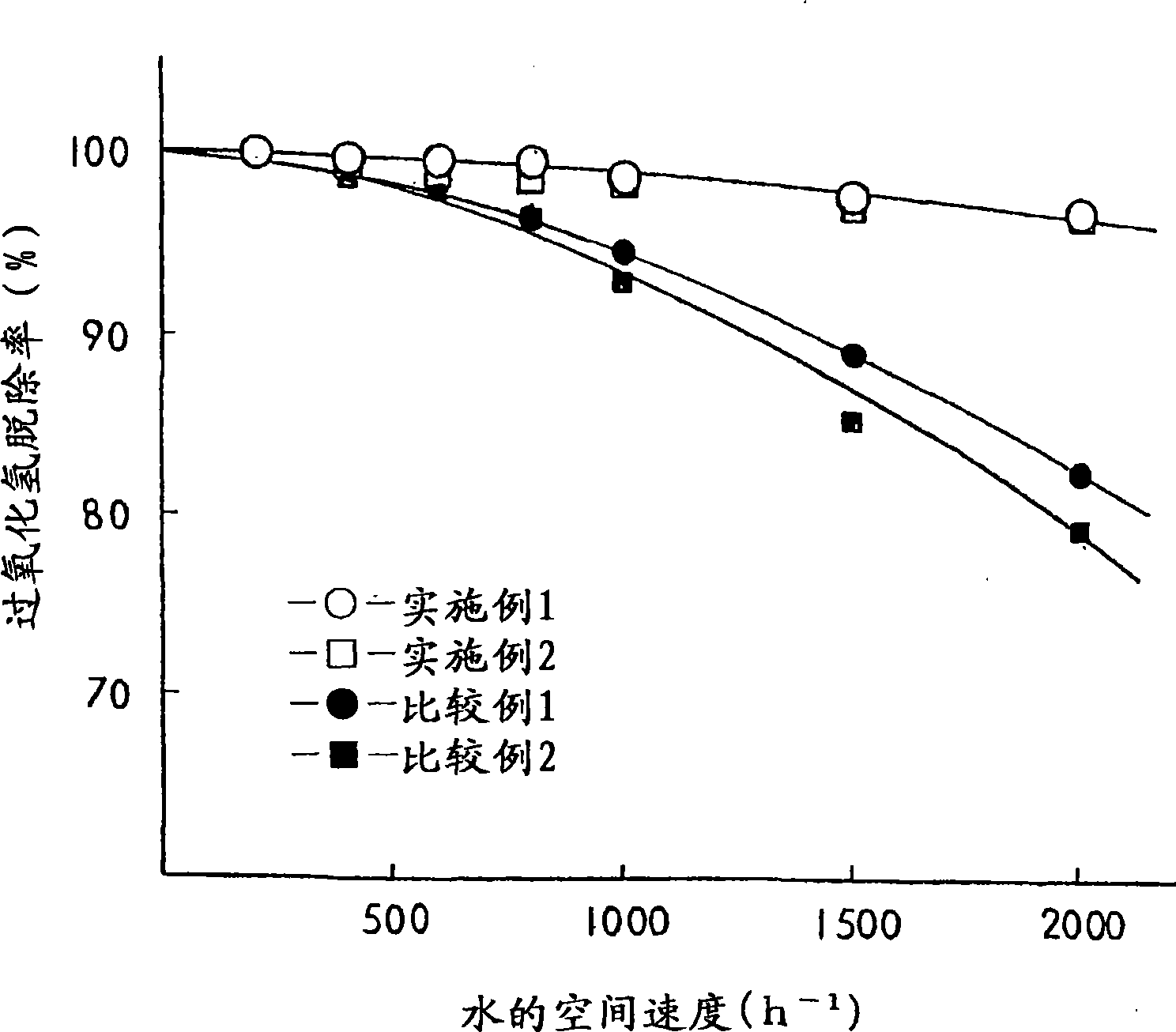

[0063] At SV=200h -1 、400h -1 、600h -1 、800h -1 、1,500h -1 and 2,000h -1 Next, ultrapure water containing 29.5 ppb (by weight) of hydrogen peroxide was passed in a downward direction through a column packed with the same hydrogen peroxide decomposition catalyst. The remova...

Embodiment 2

[0065] Carry out the same operation with those operations carried out in embodiment 1, difference is, in the catalyzer that uses, average diameter is the palladium nano colloid particle deposition of 3.5nm and is supported on the strongly basic anion exchange resin, and deposition amount is 0.07% by weight of the carrier, and ultrapure water containing 29.32 ppb (weight) was passed through the column.

[0066] At SV=1,000h -1 Under this condition, the concentration of hydrogen peroxide in the treated water discharged from the column was 0.50 ppb by weight, and the removal rate of hydrogen peroxide was 98.3%. At SV=200h -1 、400h -1 、600h -1 、800h -1 、1,500h -1 and 2,000h -1 The removal rates of hydrogen peroxide were 100.0%, 99.4%, 99.0%, 98.7%, 97.4% and 96.7%, respectively.

Embodiment 3

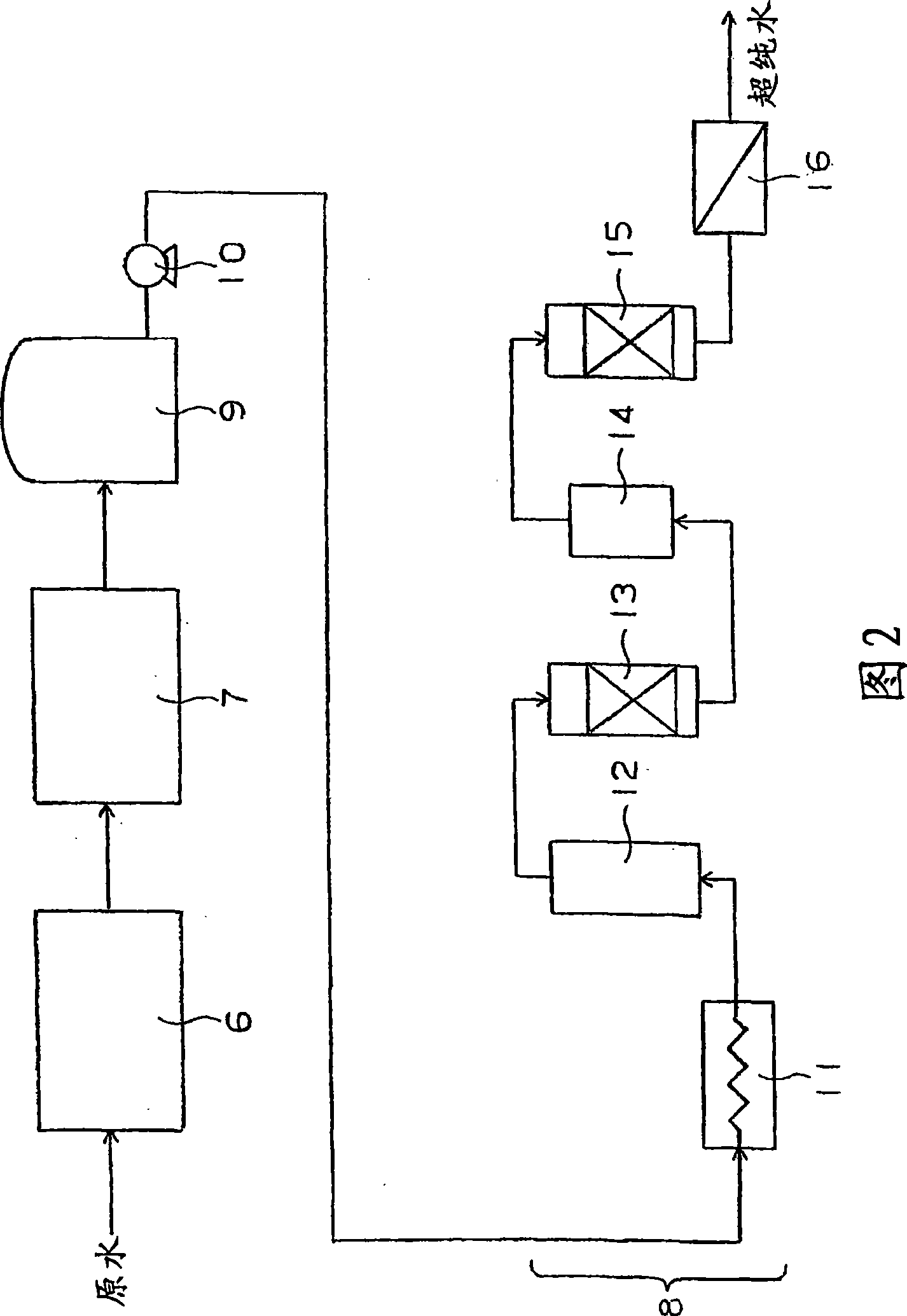

[0079] Connect a container with 10 liters of hydrogen peroxide decomposition catalyst with the outlet of the ultraviolet oxidation treatment device of the ultrapure water production device, and the hydrogen peroxide decomposition catalyst is a platinum nanogel with an average diameter of 3.5nm to be loaded The particles are deposited on the gel-type strongly basic anion exchange resin (the deposition amount is 0.07% of the weight of the carrier). A membrane degasser, a mixed bed vessel filled with anion exchange resin and an ultrafiltration unit are connected after the catalyst-filled vessel. The device made by using the 10m 3 / h flow rate to produce ultrapure water.

[0080] The concentration of hydrogen peroxide in the water flowing into the container containing the hydrogen peroxide decomposition catalyst was 15.78 ppb by weight, and the concentration of hydrogen peroxide in the treated water flowing out from the container was 0.14 ppb. The removal rate of hydrogen peroxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com