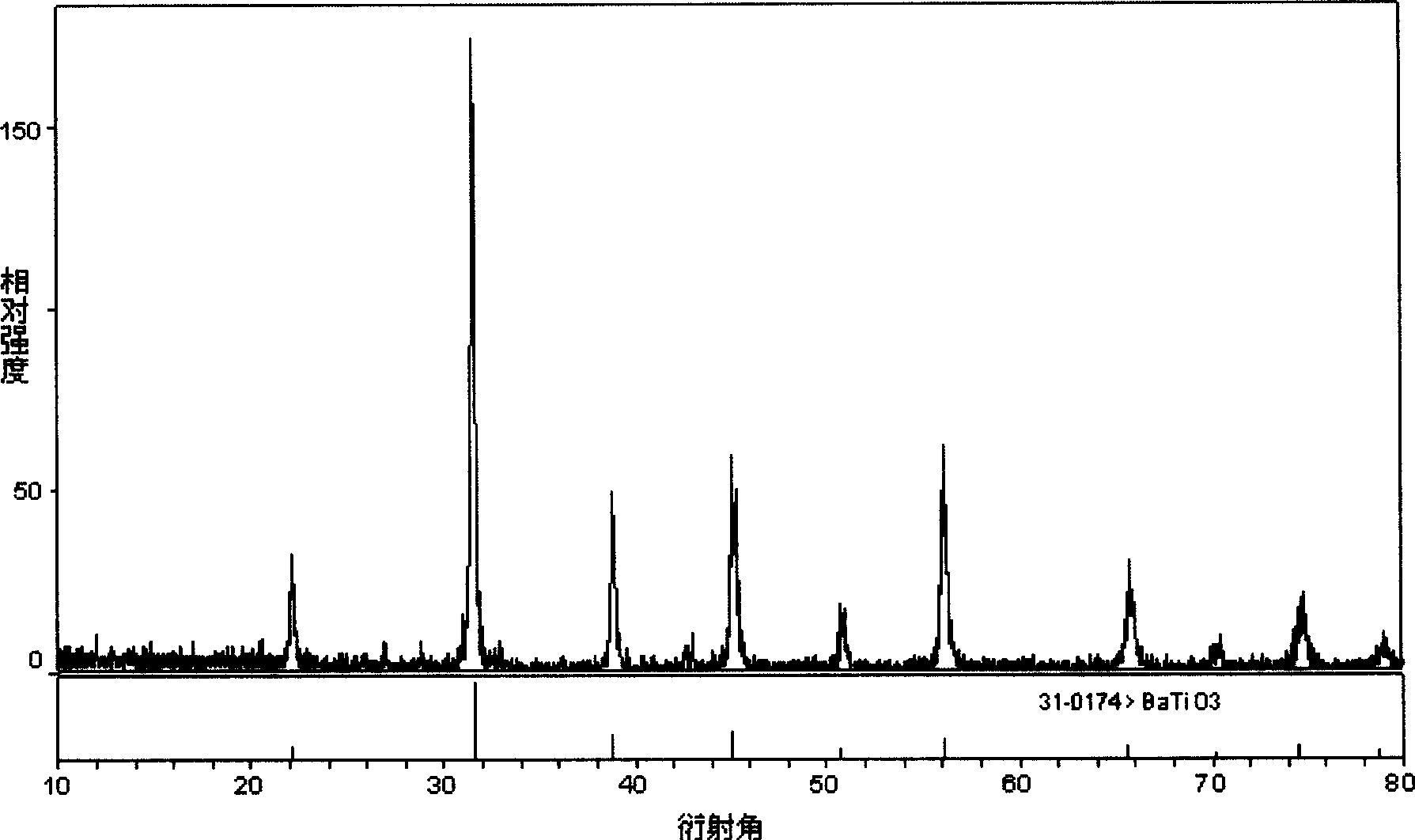

Preparation of superfine cubic phase barium titanate powder

A phase barium titanate, cubic technology, applied in the field of powder material preparation, can solve the problems of high raw material cost, complicated process, etc., and achieve the effects of reducing production cost, simple operation process and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

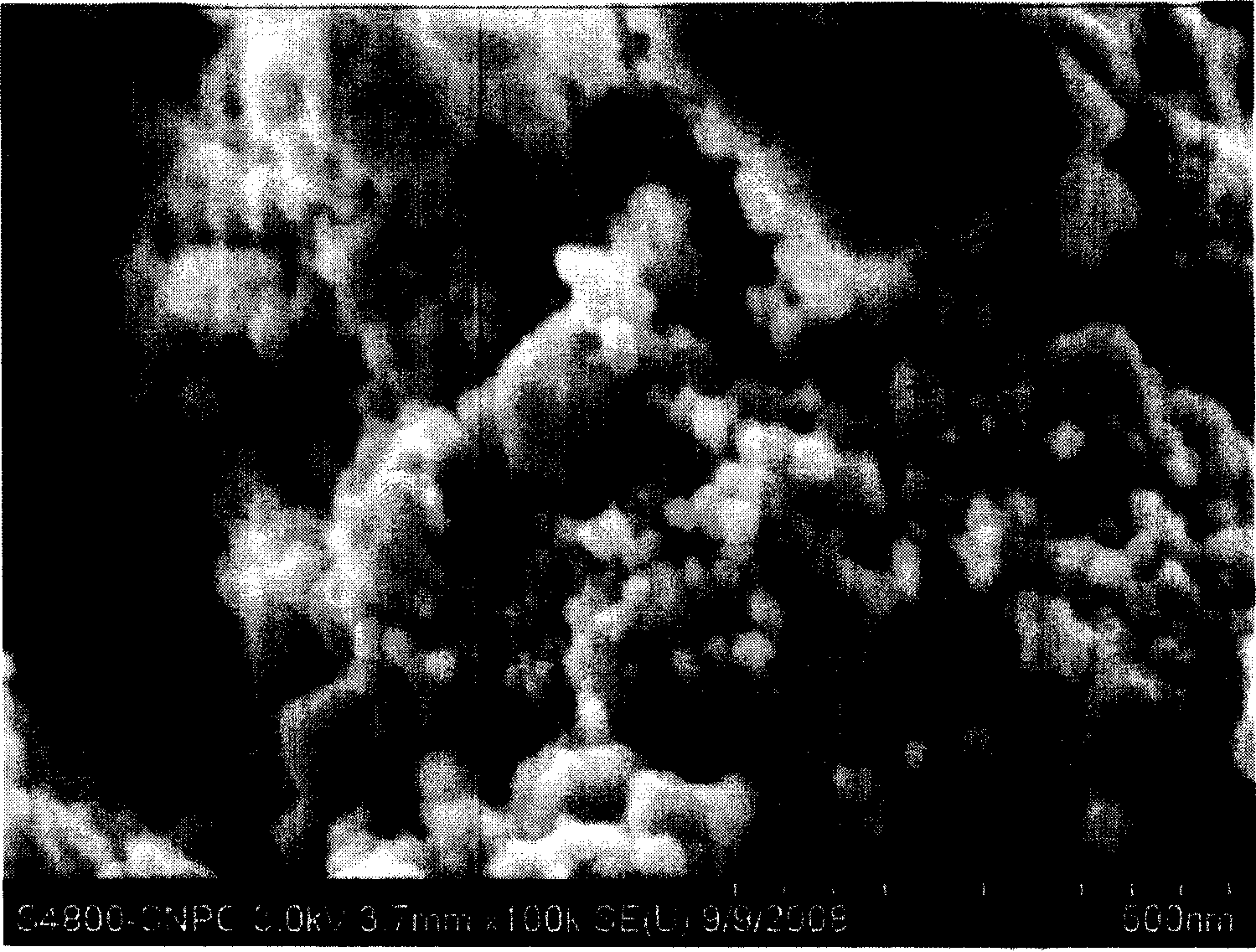

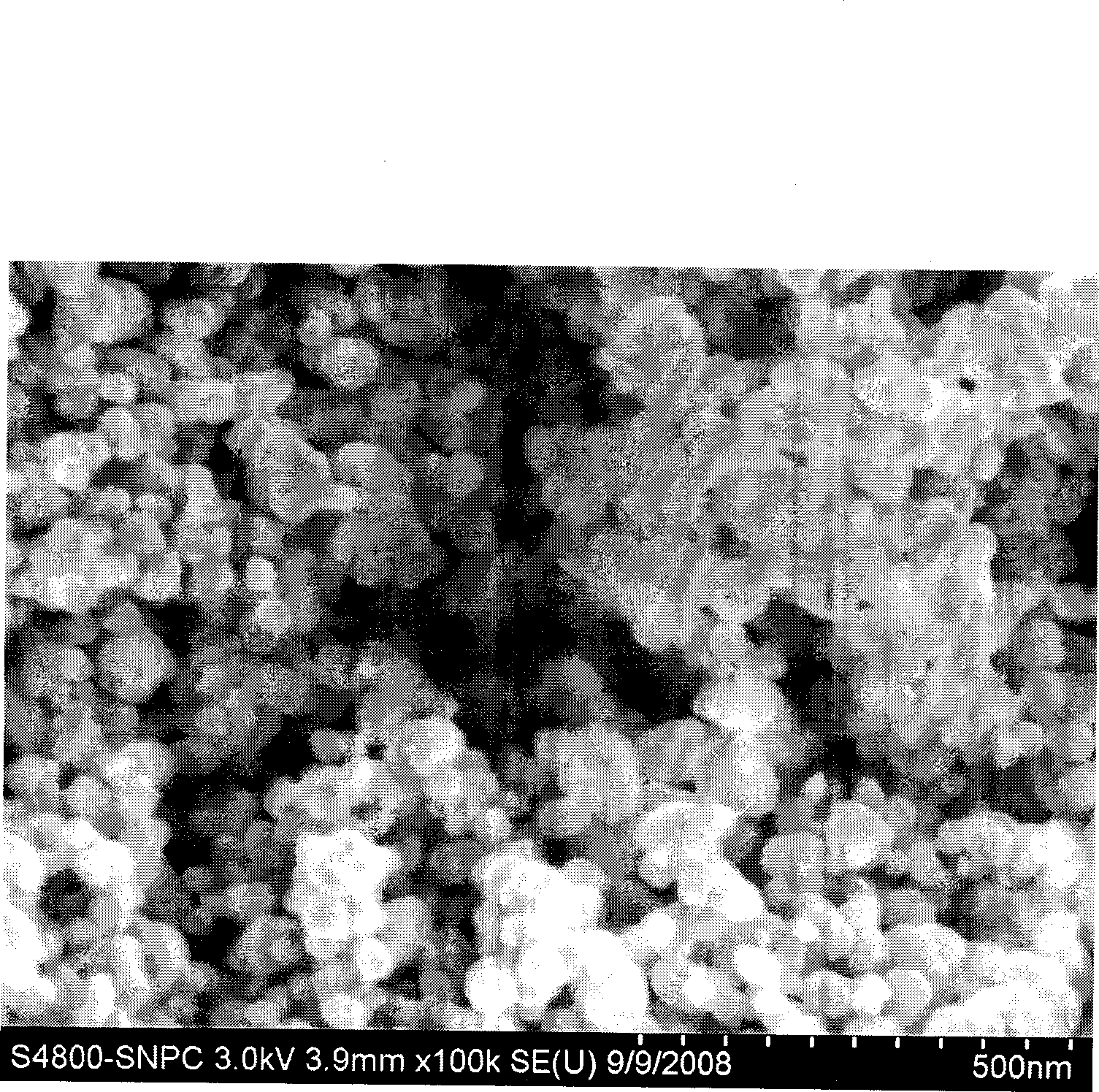

Image

Examples

Embodiment 1

[0019] a. Weigh 40g of sodium hydroxide, 10g of industrial grade metatitanic acid and 31.5g of barium hydroxide octahydrate into a 250ml beaker, add 100ml of deionized water; stir for 30 minutes.

[0020] b. Sonicate the above mixture for 60 minutes.

[0021] c. The above mixture was transferred to an autoclave, and reacted at 130° C. for 15 hours.

[0022] d. After the reaction is finished, perform suction filtration to obtain a solid, add 125 ml of 1 mol / L acetic acid to the solid, suction filter, wash with deionized water until pH = 7, dry at 60°C, and grind to obtain Ultrafine cubic barium titanate 17.50g.

Embodiment 2

[0024] a. Weigh 20g of sodium hydroxide, 5g of industrial grade metatitanic acid and 18.9g of barium hydroxide octahydrate into a 100ml beaker, add 50ml of deionized water; stir for 30 minutes.

[0025] b. Sonicate the above mixture for 30 minutes.

[0026] c. Transfer the above mixture to an autoclave, and react at 170° C. for 4 hours.

[0027] d. After the reaction is finished, centrifuge to obtain a solid, add 60ml of 1mol / L acetic acid to the solid, filter with suction, wash with deionized water to pH=7, dry at 60°C, and grind to obtain super Fine cubic phase barium titanate 7.80g.

Embodiment 3

[0029] a. Weigh 28g of potassium hydroxide, 5g of industrial grade metatitanic acid and 18.9g of barium hydroxide octahydrate into a 150ml beaker, add 50ml of deionized water; and stir for 30 minutes.

[0030] b. Sonicate the above mixture for 40 minutes.

[0031] c. Transfer the above mixture to an autoclave, and react at 150° C. for 15 hours.

[0032] d. After the reaction is finished, perform suction filtration to obtain a solid, add 60 ml of 1 mol / L acetic acid to the solid, suction filter, wash with deionized water until pH = 7, dry at 60°C, and grind to obtain Ultrafine cubic barium titanate 8.24g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com