Manufacturing process for metal thermo-insulation sandwich board

A manufacturing process and technology for sandwich panels, which are applied in metal layered products, lamination auxiliary operations, lamination devices, etc., can solve problems such as poor sealing, and achieve the effects of improving sealing, improving composite strength, and improving thermal insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

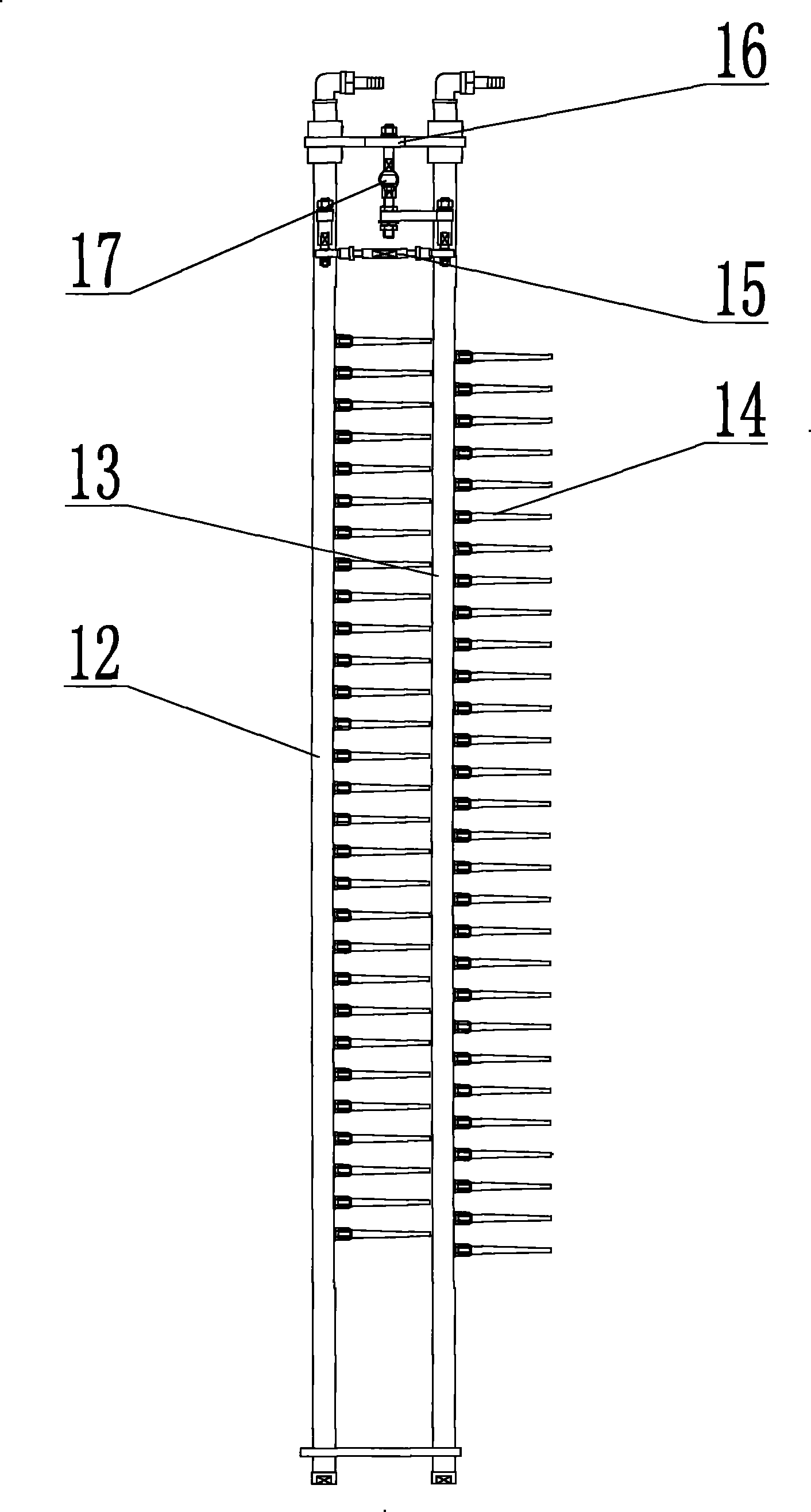

[0025] Such as image 3 As shown, it is a schematic structural diagram of a device for gluing steel plates for color steel sandwich panels. The gluing device consists of a first feed pipe 12, a second feed pipe 13, a glue outlet pipe 14, a steering mechanism 15, a bracket 16 and a cylinder 17 compositions.

[0026] The first feed pipe 12, the second feed pipe 13 are installed side by side on the support 16, the steering mechanism 15 is connected with the first feed pipe 12, the second feed pipe 13 respectively, the cylinder 17 is installed on the support 16, and The cylinder 17 is connected with the steering mechanism 15, and the glue application pipe 14 is evenly fixed on the first feed pipe 12 and the second feed pipe 13 by screws.

[0027] A manufacturing process of a metal heat-insulating sandwich panel is as follows:

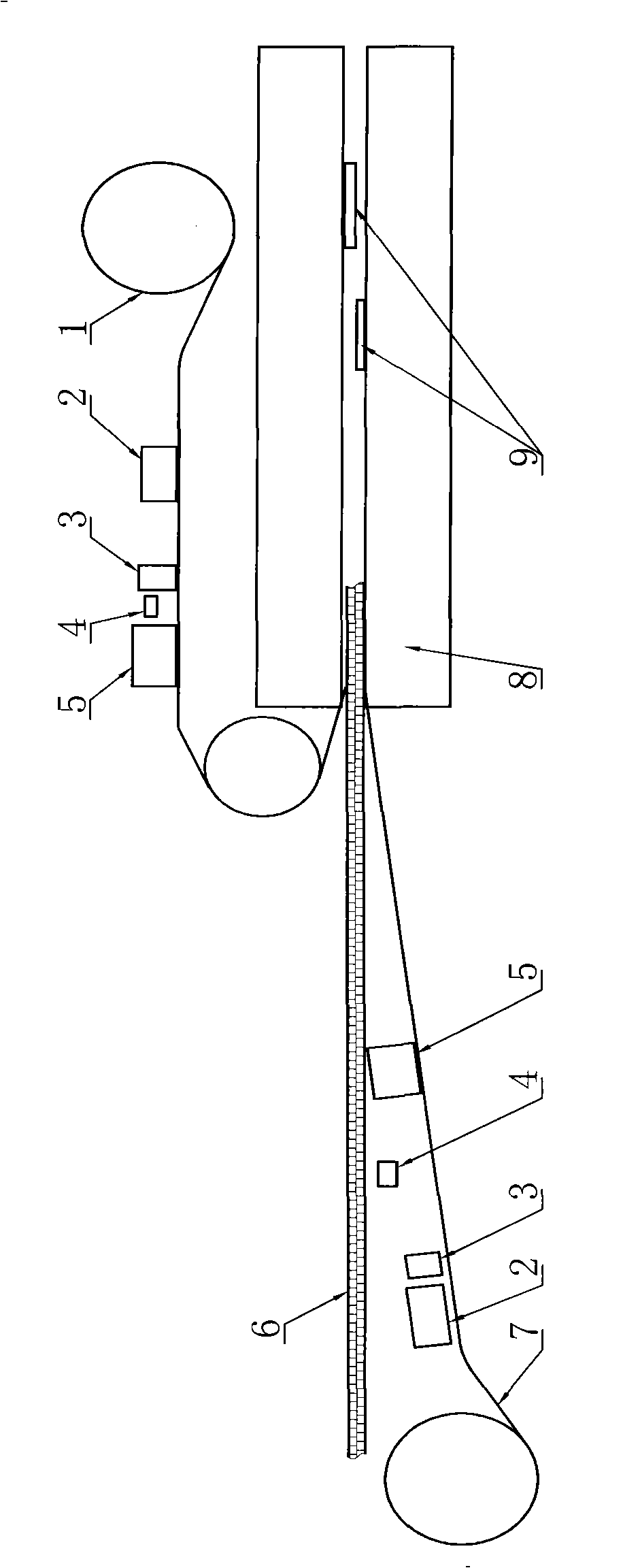

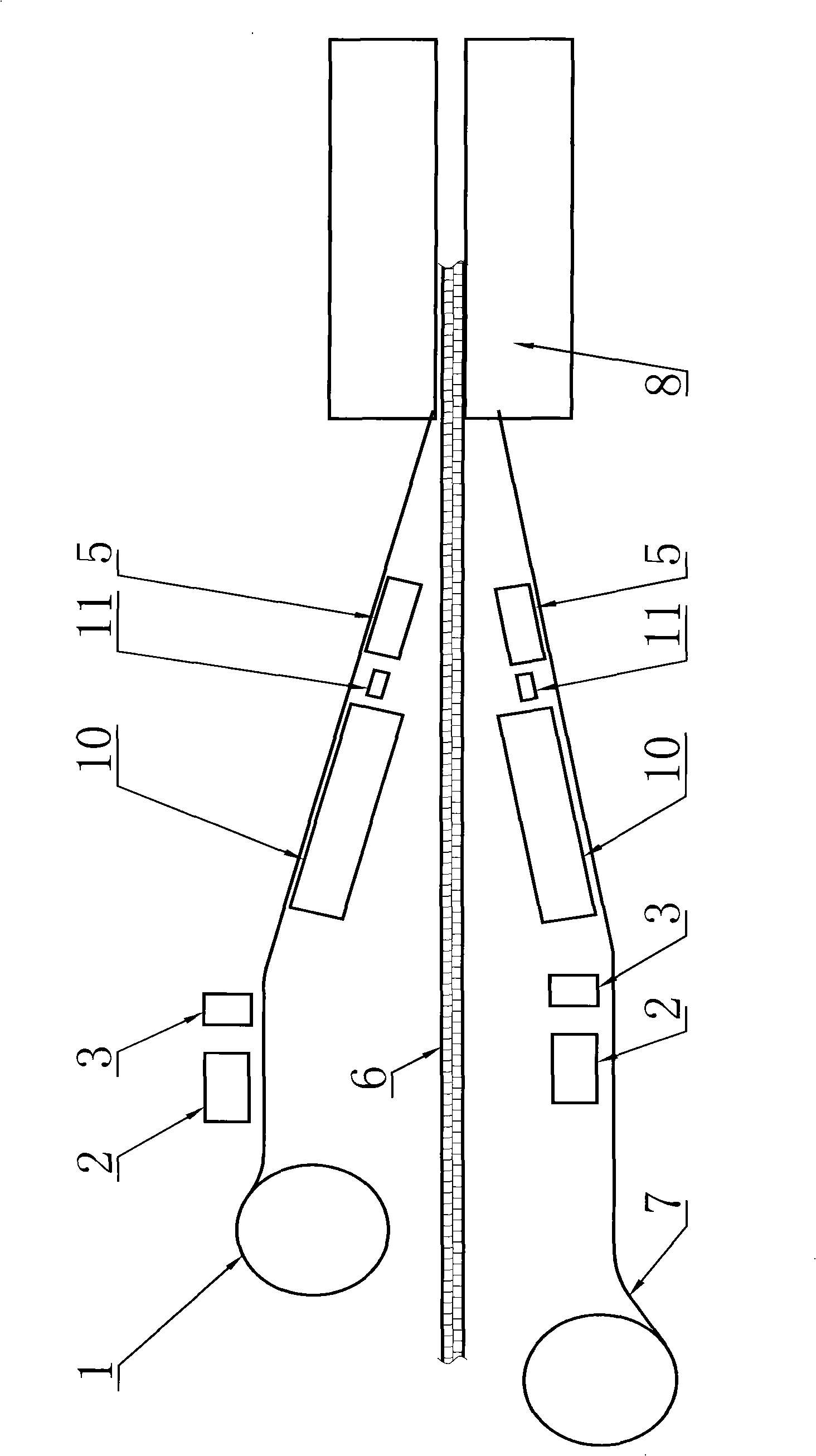

[0028] In the first step, the upper steel plate 1 and the lower steel plate 7 are cut off by the color steel coil cutting device 2 in the same direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com