Broad band oscillatory type abrasive belt grinding head and grinding method

A belt grinding and vibrating technology, which is applied in the direction of belt grinders, grinding machines, grinding/polishing equipment, etc., can solve problems affecting the grinding quality, avoid glue problems, improve precision, and obviously save energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

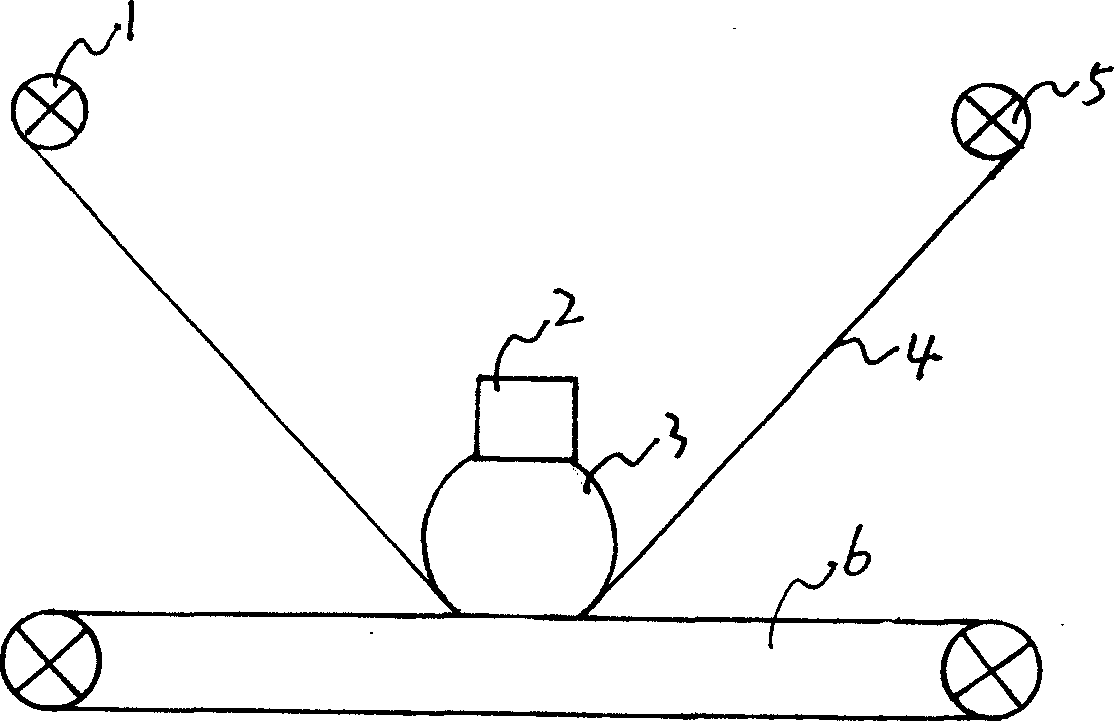

[0010] Embodiment 1: with reference to attached figure 1 . The broadband vibrating abrasive belt grinding head is composed of a vibrating grinding head 3 and a vibration source 2, and the vibration source 2 drives the vibrating grinding head 3 to vibrate and grind. The vibration source 2 is electric vibration, pneumatic vibration, magnetic vibration, hydraulic vibration or high frequency vibration. The electric vibrating mechanism adopts a motor to drive the vibrating mechanism to vibrate at low frequency, medium frequency or high frequency, and the vibrating mechanism drives the broadband vibrating grinding head to vibrate. Pneumatic vibration is the use of compressed air to drive the vibrating pneumatic components to generate low-frequency, medium-frequency or high-frequency vibrations. The vibration mechanism drives the vibration of the broadband vibrating grinding head. Its production technology is a prior art and will not be described here. Magnetic vibration is to use ...

Embodiment 2

[0011] Embodiment 2: On the basis of Embodiment 1, the vibration source 2 is installed in the vibration grinding head 3 .

Embodiment 3

[0012] Embodiment 3: On the basis of Embodiment 1, the high-frequency oscillator and the broadband vibration grinding head have an integral design structure, and directly generate low-frequency, intermediate-frequency or high-frequency vibrations after starting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com