Liquid crystal lignment, liquid crystal lignment film and liquid crystal display device

A technology of liquid crystal alignment agent and general formula, applied in the directions of liquid crystal materials, instruments, chemical instruments and methods, etc., can solve the problems of liquid crystal alignment agent, liquid crystal alignment film and liquid crystal display device without structure, inconvenience, brightness and contrast reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

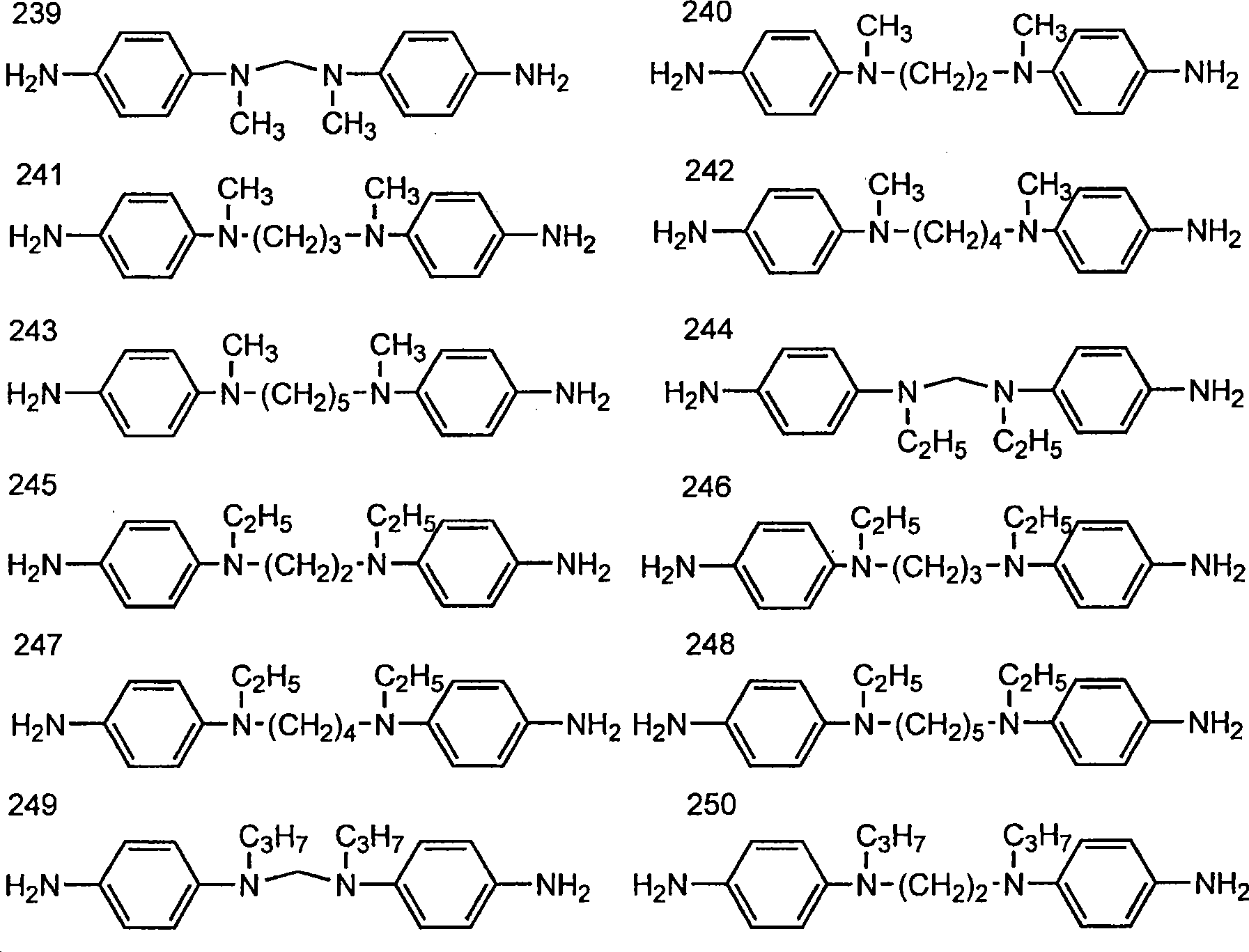

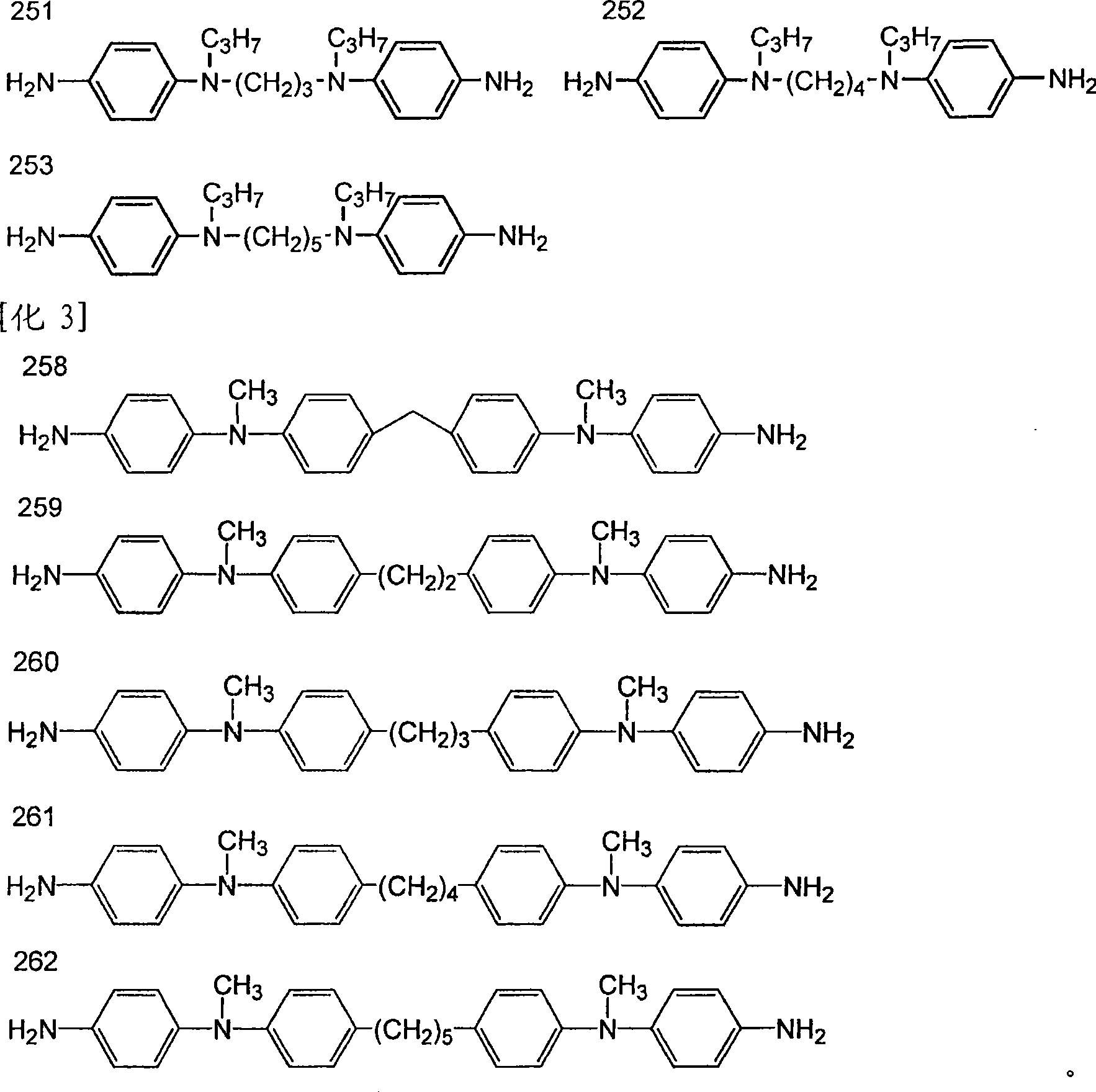

Method used

Image

Examples

Synthetic example 1

[0382] Preparation of composition A1 (varnish A1) for liquid crystal alignment film

[0383] 2.83 g of NN2DAMe and 53.4 mL of dehydrated NMP were put into a 100 mL four-neck flask equipped with a thermometer, a stirrer, a raw material inlet, and a nitrogen inlet, and stirred and dissolved under a dry nitrogen stream. While keeping the temperature of the reaction system at 5°C, 1.03g of CBDA and 1.14g of PMDA were added and allowed to react for 30 hours, then 27.7mL of BC and 13.3mL of GBL were added to prepare a polymer component with a concentration of 5wt%. Polyamic acid varnish. In the reaction of the raw materials, when the reaction temperature is raised by the heat of reaction, the reaction temperature is controlled to be about 70°C or lower to react.

[0384] Furthermore, in the examples of the present invention, the reaction was carried out while checking the viscosity during the reaction, and the reaction was terminated when the viscosity of the varnish after adding B...

Synthetic example 2~8

[0387] Preparation of various varnishes

[0388] Varnishes A2 to A8 were prepared and obtained in the same manner as in Varnish A1 except that the raw materials in Table 1 were used in the molar ratio of Table 1 below. Table 1 shows the types of raw materials of varnishes A1 to A8, their molar ratios, and the weight average molecular weight of the obtained polyamic acid.

[0389] Table 1

[0390]

[0391]

Embodiment 1

[0393] Fabrication of unit a for measuring pretilt angle, voltage retention and residual DC

[0394] A glass substrate with ITO electrodes was used as the substrate of the unit a for measurement.

[0395] The varnish A1 obtained in Synthesis Example 1 was coated on the glass substrate with the ITO electrode using a spinner. The coating conditions were 1,700 rpm and 15 seconds. After coating the film, precalcine at 80° C. for about 3 minutes, and then perform heat treatment at 230° C. for 20 minutes to form a liquid crystal alignment film with a film thickness of about 70 nm. Using a friction processing device manufactured by Iinuma GAUGE Co., Ltd., the amount of indentation of the rubbing cloth (hair length 1.8mm: rayon) is 0.40mm, the moving speed of the stage is 60mm / sec, and the roller The obtained polyimide film was subjected to a rubbing treatment at a rotational speed of 1,000 rpm to obtain a substrate for liquid crystal holding.

[0396] After ultrasonically cleaning...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| refraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com