Blue irradiance fluorophor

A phosphor, blue technology, applied in the field of blue light-emitting phosphors, to achieve the effect of high luminous brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

According to the molar ratio of Ca:Eu:Mg:Si of 0.98:0.02:1:2.00, weigh calcium carbonate powder (purity: 99.99% by mass, average particle size measured by laser diffraction scattering method: 3.87μm), europium oxide Powder (purity: 99.9% by mass, average particle size measured by laser diffraction scattering method: 2.71 μm), magnesium oxide powder (manufactured by gas phase oxidation reaction method, purity: 99.99% by mass, average particle size converted from BET specific surface area: 0.05 μm), and silica (purity: 99.9% by mass, average particle size measured by laser diffraction scattering method: 3.87 μm), wet-mixed in an ethanol medium using a ball mill for 24 hours. The obtained powder mixture is dried to evaporate ethanol. The dried powder mixture was put into an alumina crucible, and sintered at a temperature of 1050° C. for 3 hours in a mixed atmosphere of 2 vol% hydrogen-98 vol% argon.

[0027] The obtained powder sintered product was washed with a 0.1 mol / L hydrochloric...

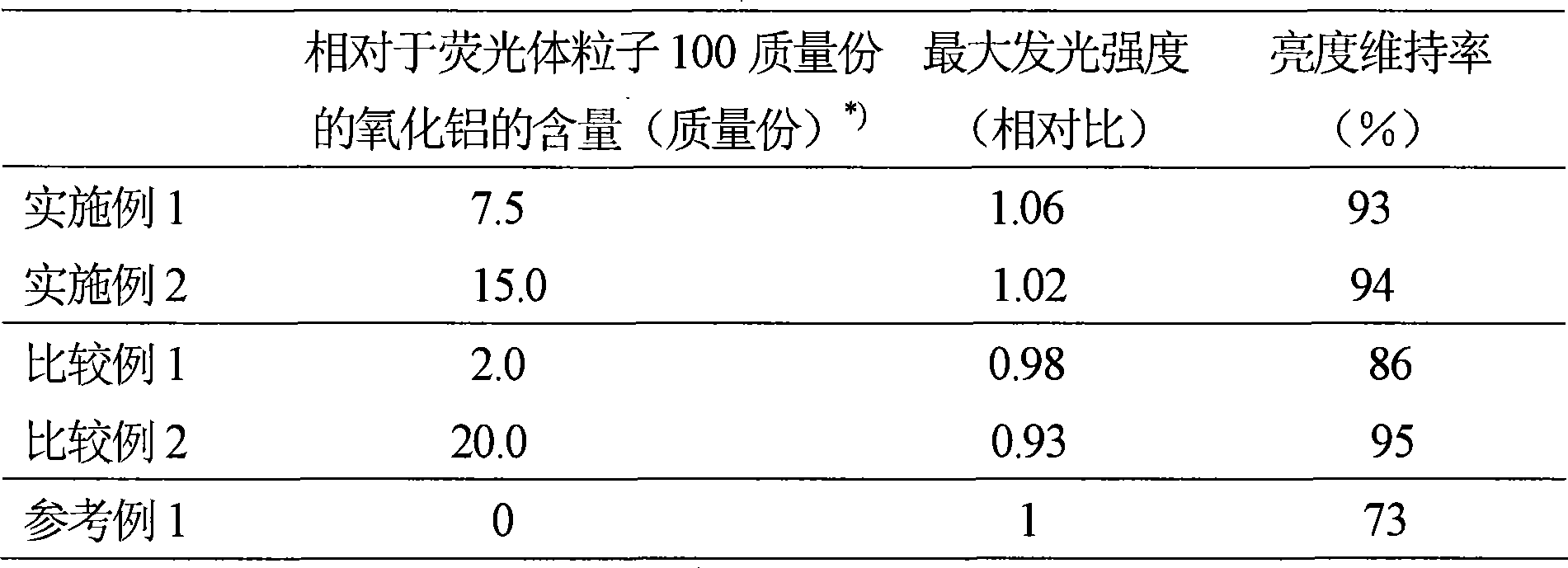

Embodiment 2

Except that the addition amount of aluminum nitrate nonahydrate relative to 1g of blue light-emitting phosphor is converted into an amount of 0.150g (15.0 parts by mass relative to 100 parts by mass of blue light-emitting phosphor particles) of alumina, the same as in the examples In the same manner as in 1, a blue light-emitting phosphor provided with an aluminum oxide film was obtained. The resulting blue light-emitting phosphor provided with an aluminum oxide film was analyzed for aluminum element distribution in the same manner as in Example 1. As a result, aluminum was uniformly detected from the surface of the phosphor particles, and the phosphor particles were confirmed to have The surface is covered by a uniform aluminum oxide film. In the same manner as in Example 1, the emission spectrum (excitation wavelength: 254 nm) of the blue light-emitting phosphor provided with this alumina coating was measured. The maximum emission intensity value of the obtained emission spectrum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com