Microcapsule suspension seed-coating agent

A technology of microcapsule and film-forming agent, which is applied in the field of agricultural microcapsule suspended seed coating, can solve the problems of short duration of medicine and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

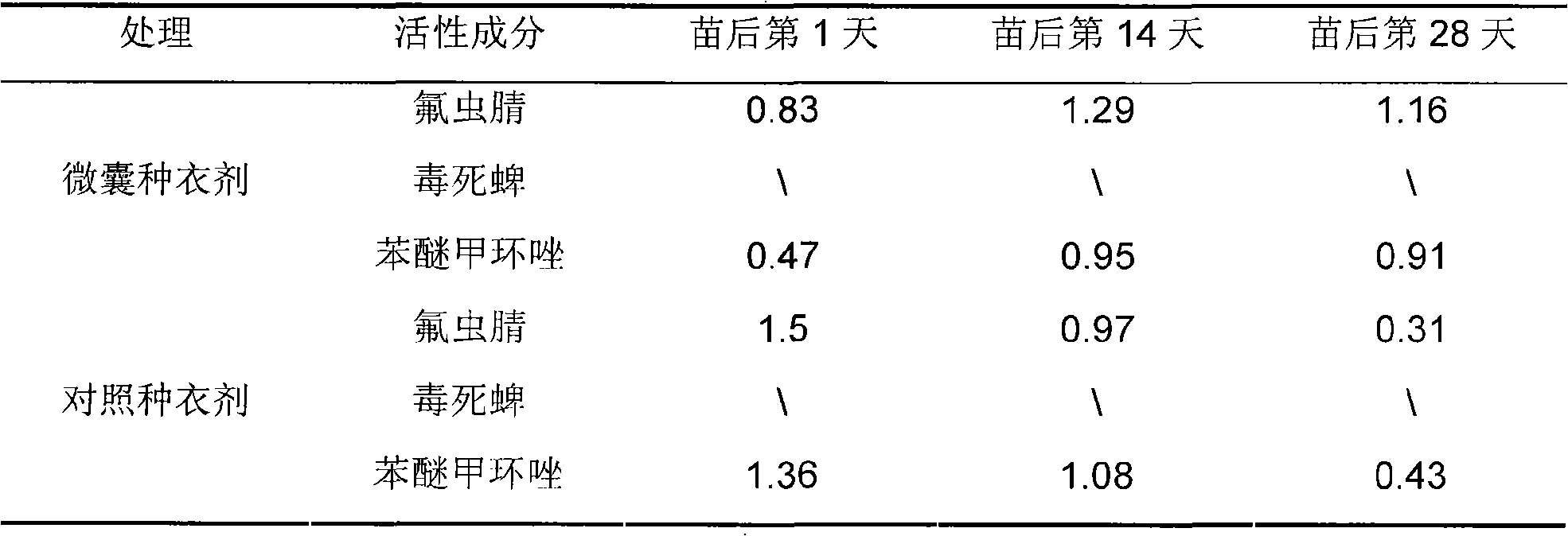

Examples

Embodiment 1

[0028] Step 1 Microcapsule Preparation

[0029] 1.0 grams of avermectin, 2.5 grams of imidacloprid, 2.0 grams of tebuconazole, and 5.5 grams of polystyrene were dissolved in 50 milliliters of dichloromethane, and they were added to 1000 milliliters containing 1.5% hydroxyethyl cellulose and 1.2% polystyrene while stirring. Nongru 600# aqueous solution. Use a high-speed shear emulsifier to emulsify it until the emulsion droplets are 1-5 microns.

[0030] First, the above emulsion was mechanically stirred at room temperature for 3 hours to volatilize most of the dichloromethane, and then slowly heated to 40° C. to completely volatilize the remaining dichloromethane. Centrifuge, remove the supernatant, and then wash 3 times with deionized water to obtain microcapsules containing abamectin imidacloprid tebuconazole, the total amount of abamectin imidacloprid tebuconazole in the microcapsules is 50.0%.

[0031] The second step microcapsule water-based suspension

[0032] Add 1....

Embodiment 2

[0034] Step 1 Microcapsule Preparation

[0035] 5.0 grams of fipronil, 2.0 grams of imidacloprid, 3.0 grams of tebuconazole, and 10.0 grams of polymethyl methacrylate were dissolved in 100 milliliters of dichloromethane, and added to 2000 milliliters of 1.3% polyvinyl alcohol and 1.5% pesticides while stirring. Milk 603# aqueous solution. Use a high-speed shear emulsifier to emulsify it until the emulsion droplets are 1-5 microns.

[0036] First, the above emulsion was mechanically stirred at room temperature for 4 hours to volatilize most of the dichloromethane, and then slowly heated to 40° C. to completely volatilize the remaining dichloromethane. Centrifuge, remove the supernatant, and then wash with deionized water 3 times to obtain microcapsules containing fipronil, imidacloprid, tebuconazole, the total amount of fipronil, imidacloprid, tebuconazole in the microcapsules is 50.0 %.

[0037] The second step microcapsule water-based suspension

[0038] Add 2.3 grams of ...

Embodiment 3

[0040] Step 1 Microcapsule Preparation

[0041] Dissolve 1.0 grams of fipronil, 10.0 grams of chlorpyrifos, 3.0 grams of difenoconazole, and 14.0 grams of polystyrene-maleic anhydride alternating copolymer in 150 milliliters of chloroform, and add to 2500 milliliters containing 1.7% Hydroxypropyl cellulose and 1.0% Nongru 0203 aqueous solution. Use a high-speed shear emulsifier to emulsify it until the emulsion droplets are 1-5 microns.

[0042] Stir the above emulsion mechanically at room temperature for 10 minutes, heat to 40°C within 1 hour, and then slowly raise the temperature to 61°C to completely volatilize the remaining chloroform. Centrifuge, remove the supernatant, and wash with deionized water for 3 times to obtain the microcapsules containing fipronil·chlorpyrifos·difenoconazole, the content of fipronil·chlorpyrifos·difenoconazole in the microcapsules The total amount is 50.0%.

[0043] The second step microcapsule water-based suspension

[0044] Add 1.7 grams of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com