Erasable viscous ink and preparation thereof

An ink and viscosity technology, applied in the field of ink composition and preparation, can solve the problems of ink falling off, ink not easy to wipe clean, ink pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1 prepares black ink

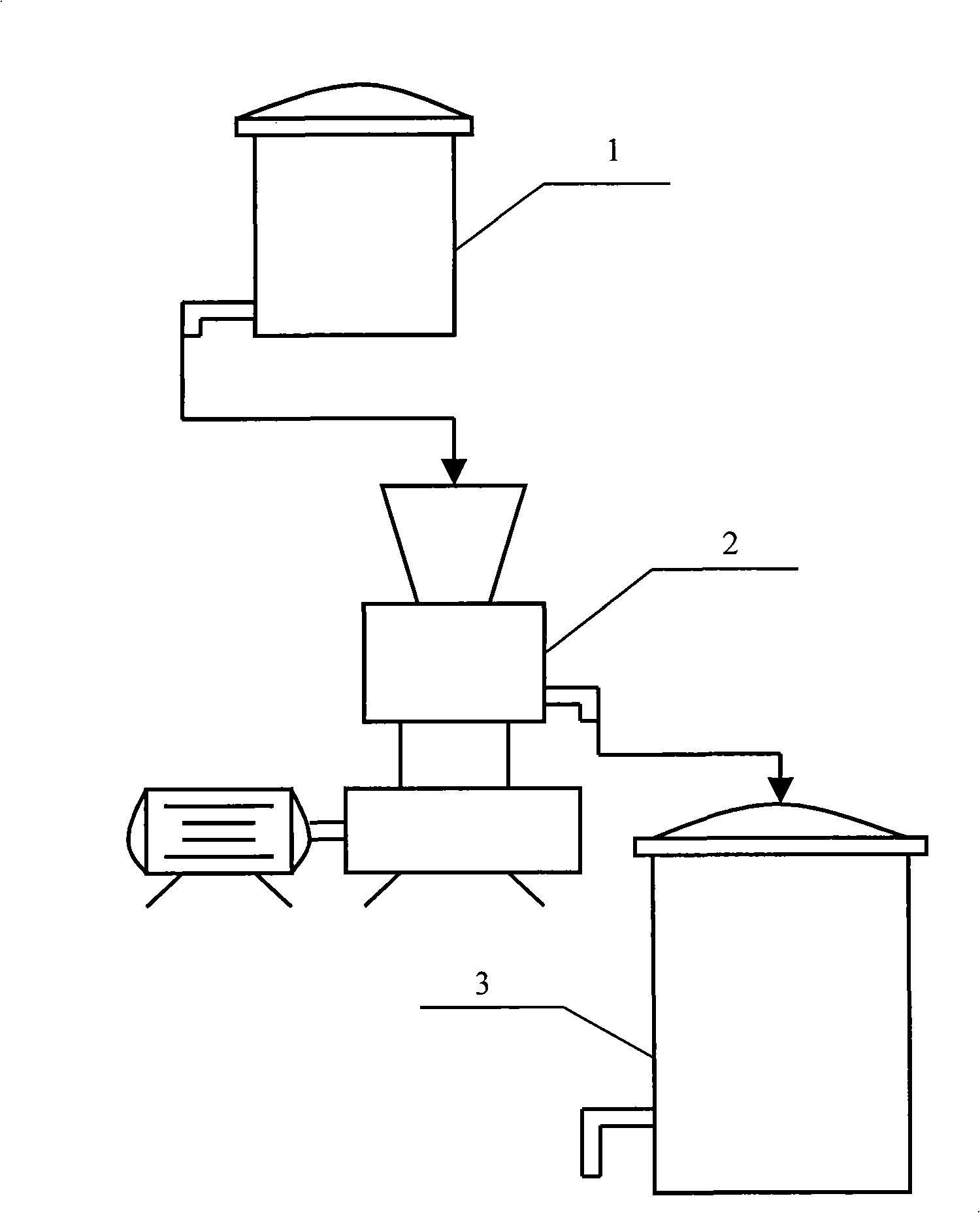

[0021] Add 65 grams of solvent ethanol; 5 grams of butanol; 5 grams of propanol into the heating tank 1 in turn, and then put 2 grams of vinyl resin copolymer; After being dissolved into a colloid, 7 grams of Lithol Scarlet; 1.5 grams of wetting and dispersing agent sodium methylene bis-naphthalene sulfonate; 1.5 grams of electrically neutral salt synthesized from polycarboxylic acid and amine derivatives; 2 grams of emulsifier Tween 2 grams of Span; 4 grams of stripping agent polypropylene glycol; 3 grams of polyethylene glycol, fully stir, when the temperature is heated to 65 degrees, keep for 1 hour, after the various components are completely dissolved, naturally drop to normal temperature, and then Transport it to the colloid mill 2 for circular grinding, release it when the particle size is less than 10 microns, filter through the filter 3, and clean it for filling to become a finished product.

Embodiment 2

[0022] Embodiment 2 prepares red printing ink

[0023] Add 65 grams of solvent ethanol; 5 grams of butanol; 5 grams of propanol into the heating tank 1 in turn, and then put 2 grams of vinyl resin copolymer; After being dissolved into a colloid, 7 grams of Lithol Scarlet; 1.5 grams of wetting and dispersing agent sodium methylene bis-naphthalene sulfonate; 1.5 grams of electrically neutral salt synthesized from polycarboxylic acid and amine derivatives; 2 grams of emulsifier Tween 2 grams of Span; 4 grams of stripping agent polypropylene glycol; 3 grams of polyethylene glycol, fully stir, when the temperature is heated to 65 degrees, keep for 1 hour, after the various components are completely dissolved, naturally drop to normal temperature, and then Transport it to the colloid mill 2 for circular grinding, release it when the particle size is less than 10 microns, filter through the filter 3, and clean it for filling to become a finished product.

Embodiment 3

[0024] Embodiment 3 prepares blue ink

[0025] Add 40 grams of solvent ethanol; 10 grams of butanol; 10 grams of propanol to heating tank 1 in turn, then add 3 grams of vinyl resin copolymer; 1 gram of polyvinyl pyrrolidone; keep stirring until it is fully dissolved into a colloid 13 grams of phthalocyanine blue; 3 grams of wetting and dispersing agent sodium methylene bis-naphthalene sulfonate; 1 gram of electrically neutral salt synthesized from polycarboxylic acid and amine derivatives; 3 grams of emulsifier Tween; 2 grams of Span; 6 grams of polypropylene glycol; 8 grams of polyethylene glycol, fully stirred, when the temperature was heated to 65 degrees, kept for 1 hour, after the various ingredients were completely dissolved, naturally dropped to normal temperature, and then transported to the colloid mill 2 for Circular grinding, release when the particle size is less than 10 microns, filter through the filter 3, and then clean and fill to become the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com