Preparation of biomimetic material

A biomimetic material, polysuccinimide technology, applied in the field of fine chemicals in chemical engineering, can solve the problems of poor mechanical strength and high expansion, and achieve the effects of improving mechanical strength, good environmental compatibility and improving softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

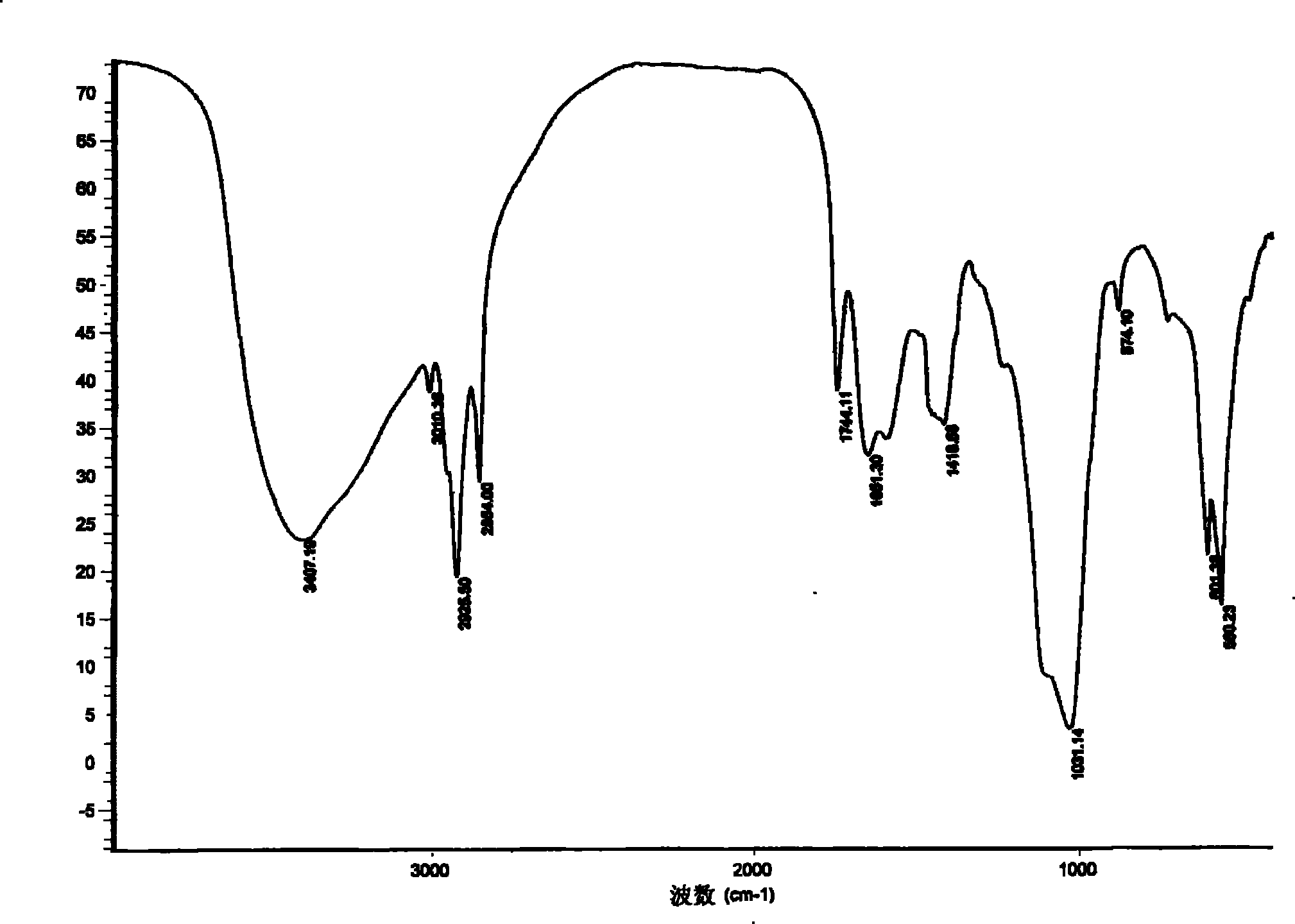

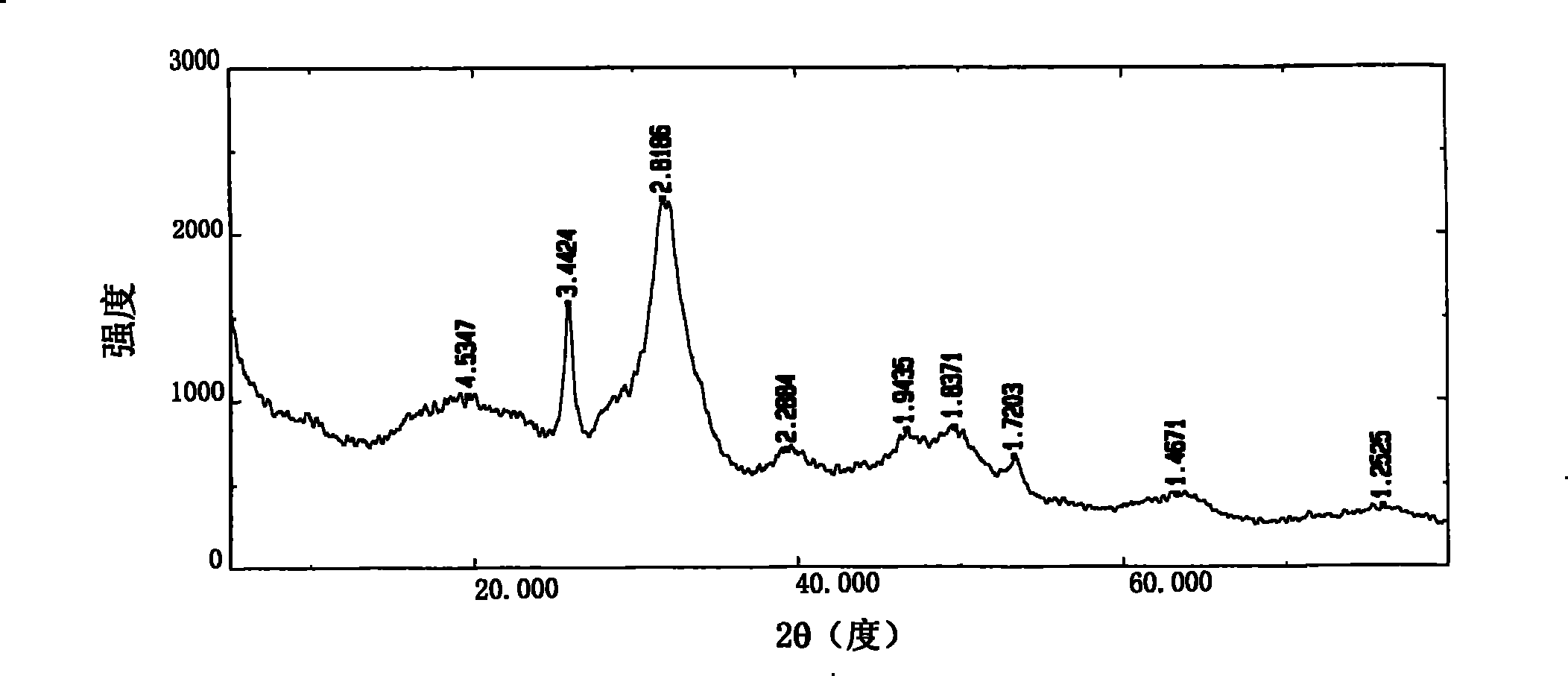

Image

Examples

Embodiment 1

[0057] Embodiment 1: In the process of preparing polyaspartic acid or its derivatives, chitosan, lecithin and calcium phosphorus compound composite material, use organic solvent method to prepare polyaspartic acid containing at least one amino side chain and Its derivative, the method comprises the following steps:

[0058] (1) Preparation of polyaspartic acid and derivatives thereof having at least one amine side chain. The method is to react polysuccinimide with polyamine or its hydrochloride in an organic solvent (such as dimethylformamide). Molar ratio of polyamine to polysuccinimide (according to succinimide unit): 0.05-1.0:1, reaction temperature 20-100°C, reaction time 1-10 hours. After the reaction is complete, add anhydrous methanol or anhydrous ethanol to precipitate the product, filter, and vacuum-dry the filter cake at 40-60°C for 4 hours to obtain a partially ring-opened polysuccinimide containing at least one amine side chain.

[0059] The raw material polysucc...

Embodiment 2

[0068] Example 2: In the process of preparing polyaspartic acid or its derivatives, chitosan, lecithin and calcium phosphorus compound composite materials, an aqueous medium method is used to prepare polyaspartic acid containing at least one amino side chain and derivatives thereof, the method comprises the following steps:

[0069] (1) Prepare an aqueous solution of polyaspartic acid and its derivatives containing at least one amino side chain. The method is to dissolve the polyamine containing at least two amine groups in the aqueous solution containing alkali, the molar ratio of polyamine to alkali is: 1:9-9:1; Molar ratio of amines (according to succinimide units): 0.05-1.0:1 mixing, reaction temperature 20-100°C, reaction time 0.1-10 hours.

[0070] The mixing mode of above-mentioned polyamine and polysuccinimide can be under agitation, polyamine solution is all, or in batches, or is added step by step in polysuccinimide suspension slurry in water and goes, or Add polys...

Embodiment 3

[0080] Example 3: In the process of preparing polyaspartic acid or its derivatives, chitosan, lecithin and calcium phosphorus compound composite materials, an aqueous medium method is used to prepare polyaspartic acid containing at least one amino side chain and derivatives thereof, the method comprises the following steps:

[0081] (1) Prepare an aqueous solution of polyaspartic acid and its derivatives containing at least one amino side chain. The method is to mix an aqueous solution of polyamine containing at least two amine groups, a hydrolysis agent and / or an aminolysis agent with polysuccinimide, the reaction temperature is 20-100° C., and the reaction time is 0.5-10 hours to obtain at least Polyaspartic acid with an amine side chain and its derivatives or an aqueous solution thereof. The molar ratio of the total moles of polyamine, hydrolysis agent and aminolysis agent to polysuccinimide calculated as succinimide units is: 1-5:1. The polyamine used may be one or a mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com