Mount press forming mold

A stamping die and fan bone technology, applied in the field of fan bone production equipment, can solve the problems of poor processing quality, environmental pollution, low processing efficiency, etc., and achieve the effects of high production efficiency, stable forming quality, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

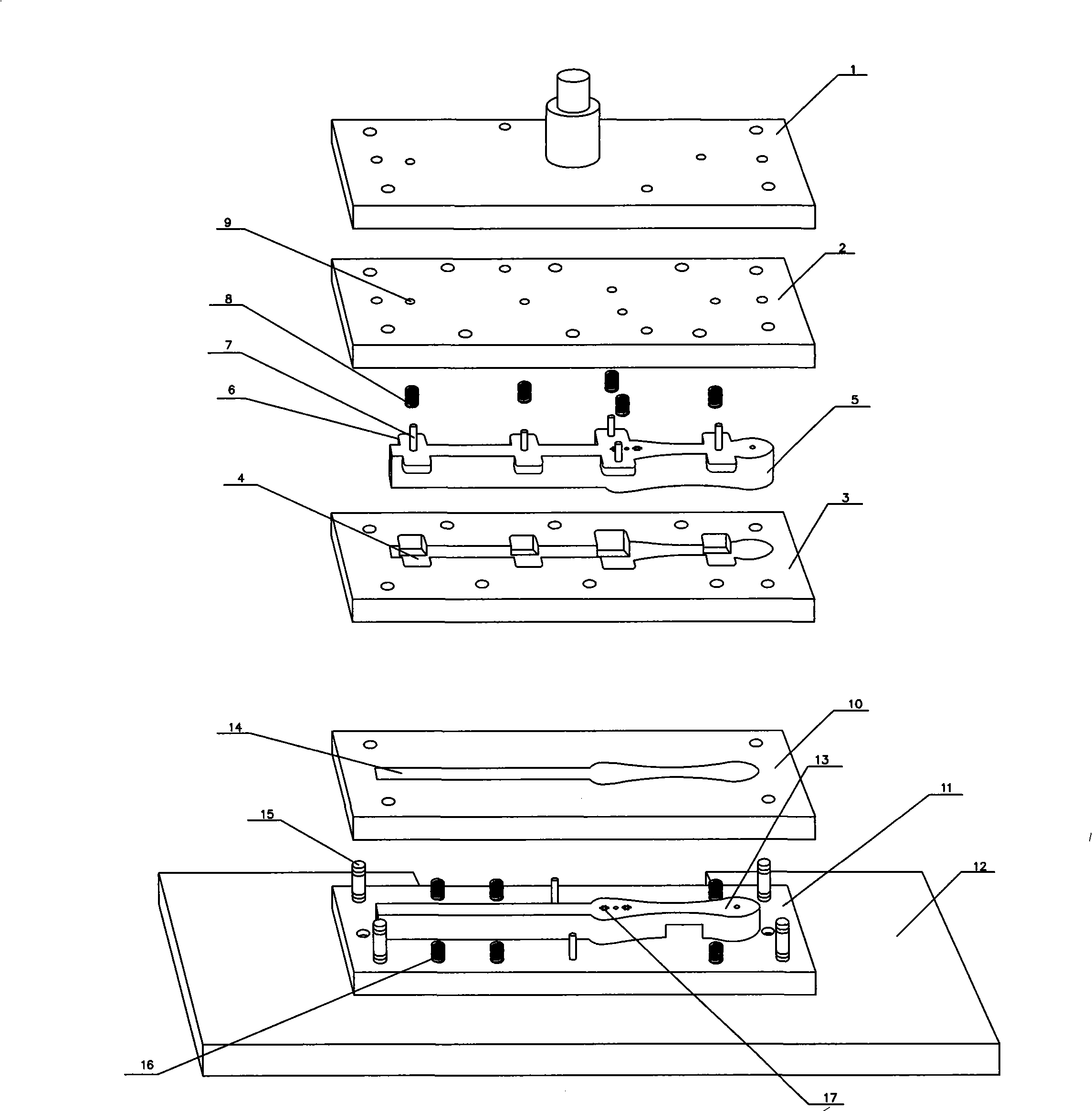

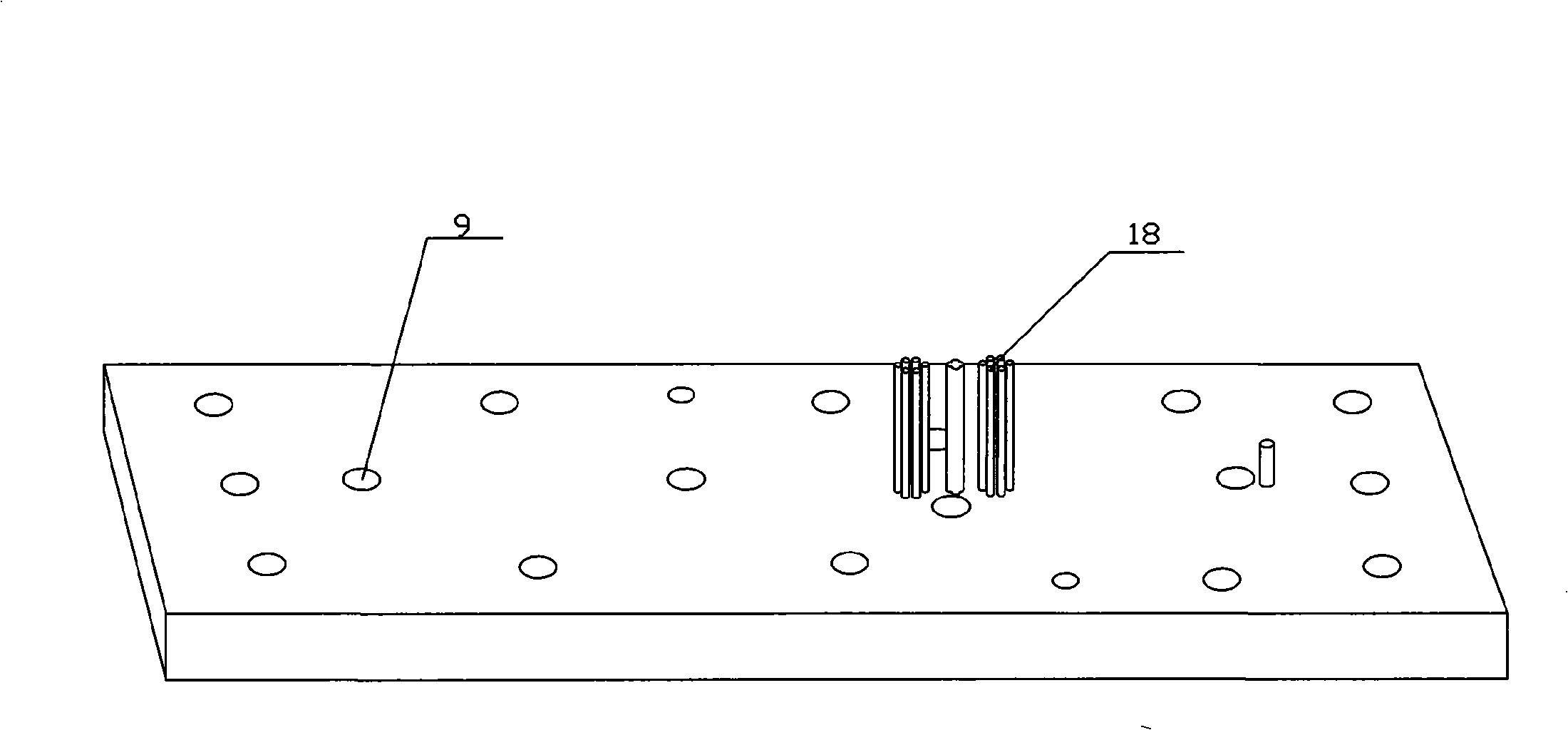

[0012] The fan rib stamping die of the present invention comprises a male mold and a female mold. The male mold is composed of an upper mold base 1, an upper middle base 2, and an upper panel 3 sequentially stacked from top to bottom. The upper mold base 1 and the upper middle base 2 are connected by pins, the upper middle seat 2 and the upper panel 3 are connected by pins, the upper panel 3 is provided with a through hole 4 adapted to the shape of the upper mold core, and the upper mold core 5 is slidably arranged in the upper panel 3, and the upper The mold core 5 is provided with a block 6 that prevents it from falling out of the upper panel 3. There is a pin 7 on the top of the upper mold core 5, and the pin 7 is passed through the guide hole 9 of the upper middle seat, and on the pin 7 The spring 8 presses the upper mold core 5 against the upper panel 3;

[0013] The female mold is composed of a lower panel 10, a lower middle seat 11, and a lower mold base 12 sequentially...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com