Electrical control cable

一种控制电缆、电气控制的技术,应用在电力电缆、绝缘电缆、电气元件等方向,能够解决昂贵等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

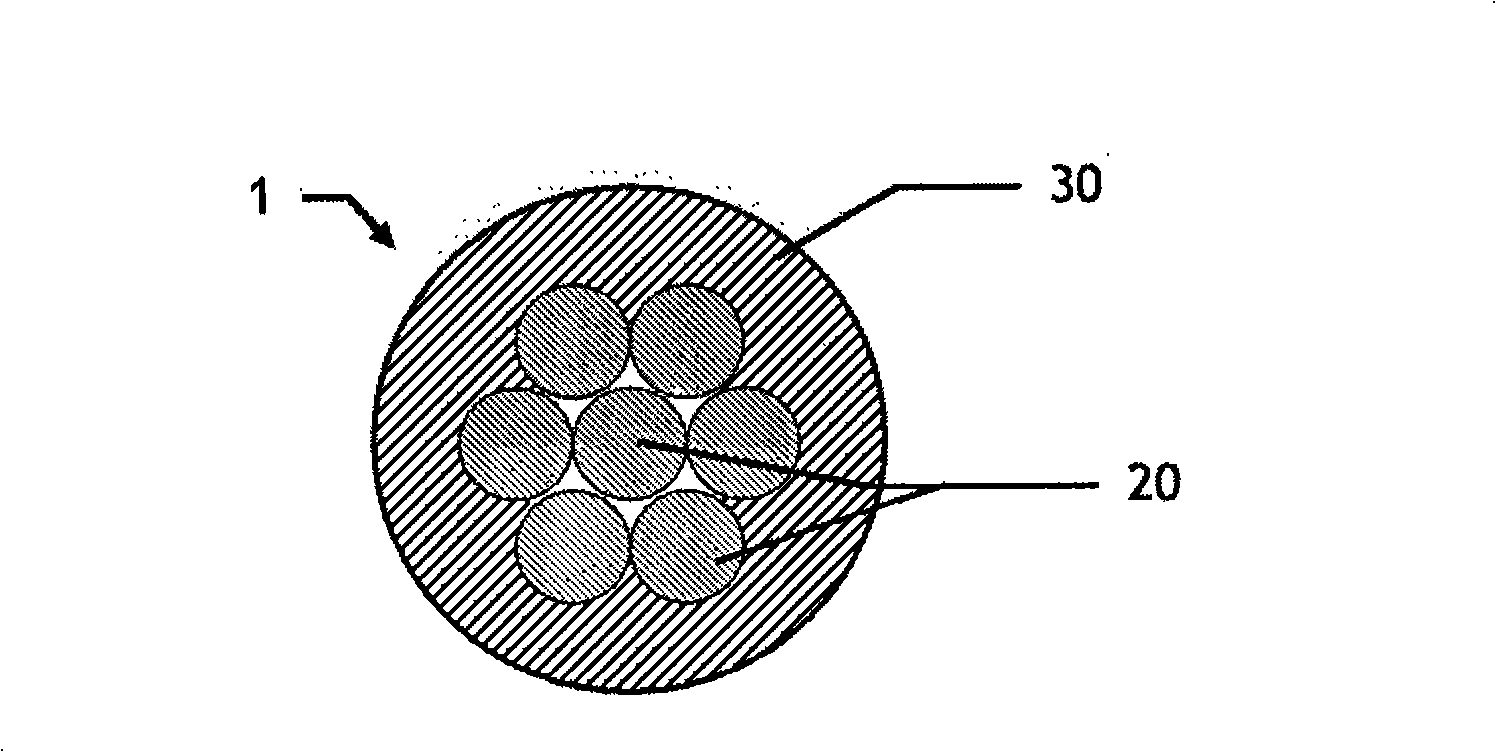

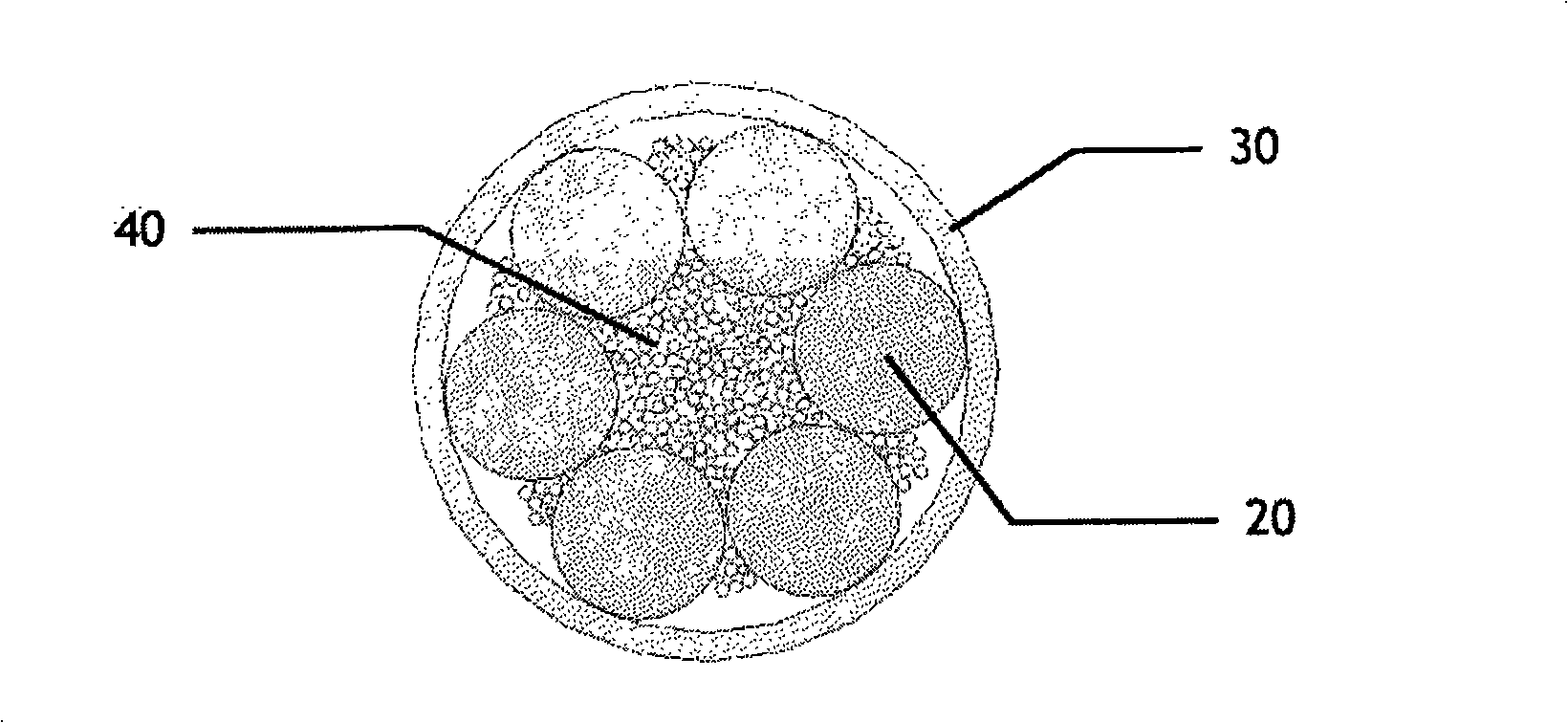

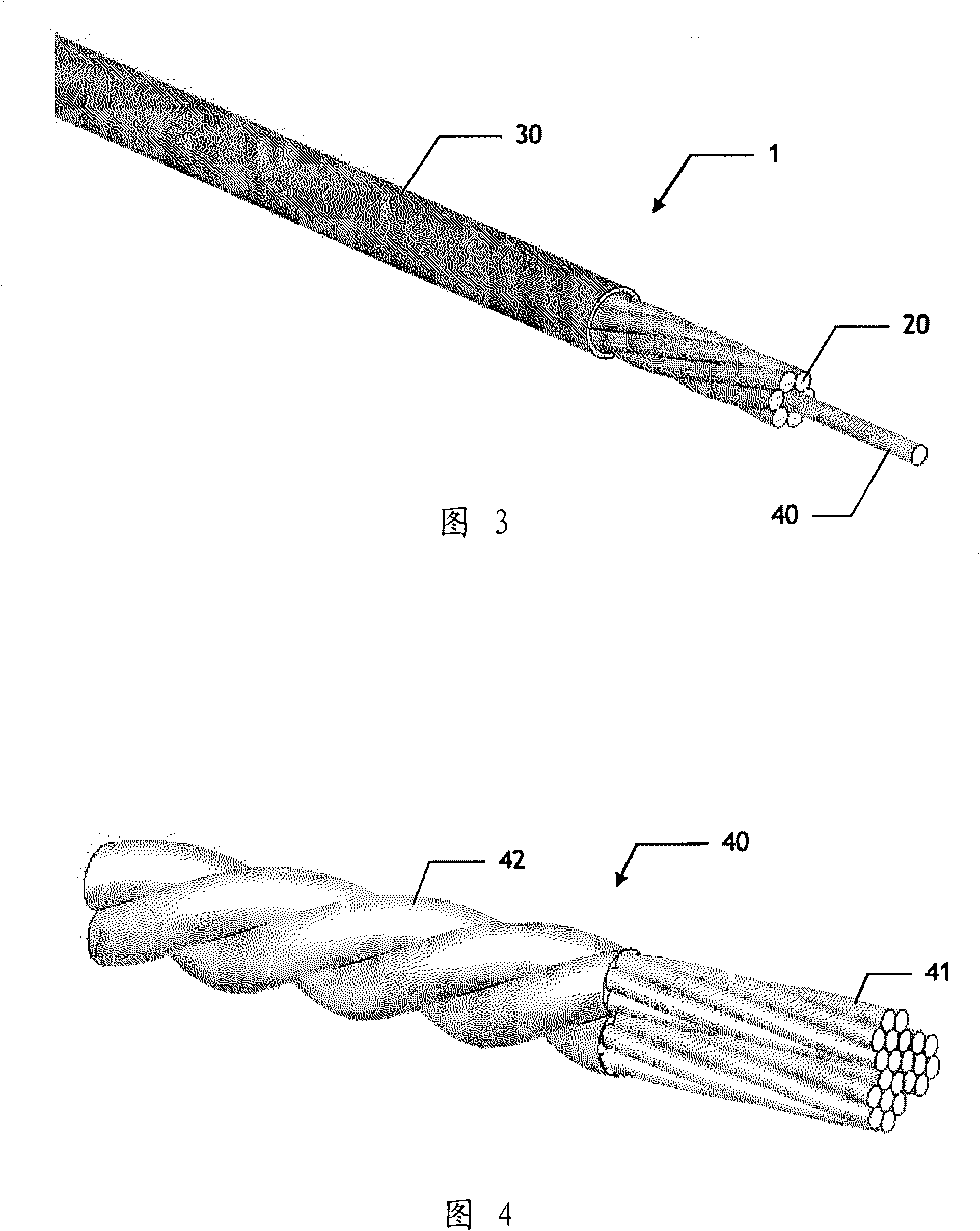

[0024] Figure 3 shows a part of a cable 1 constituting a first possible embodiment with its ends stripped to reveal the intermediate structure of said cable.

[0025] Like the prior art cables described in U.S. Patent No. 7,145,082, the cable 1 in FIG. together extend in the longitudinal direction of the central core 40 of the multi-fiber aggregate.

[0026] However, since these strands are evenly and concentrically distributed around the core 40 , in contact with each other and with the core in pairs, the number of strands 20 used is reduced. In the non-limiting embodiment shown, the number of these strands 20 is six. For the core and the rest of the strands, the number of whole copper strands must naturally be adapted to wrap around the core in a single layer.

[0027] The polymeric fibers of the core 40, for example composed of aramid fibers, are secured to each other only by an external adhesive coating to form a non-metallic monolithic structure. This step in the manuf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com