Tap switch lead cold pressing equipment

A technology of tap changer and lead wire, which is applied in the direction of connection, line/collector parts, electrical components, etc. It can solve the problems of unreliable crimping, low work efficiency, and inconsistent compression and tightness, so as to improve work efficiency and operation Convenience, crimping and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

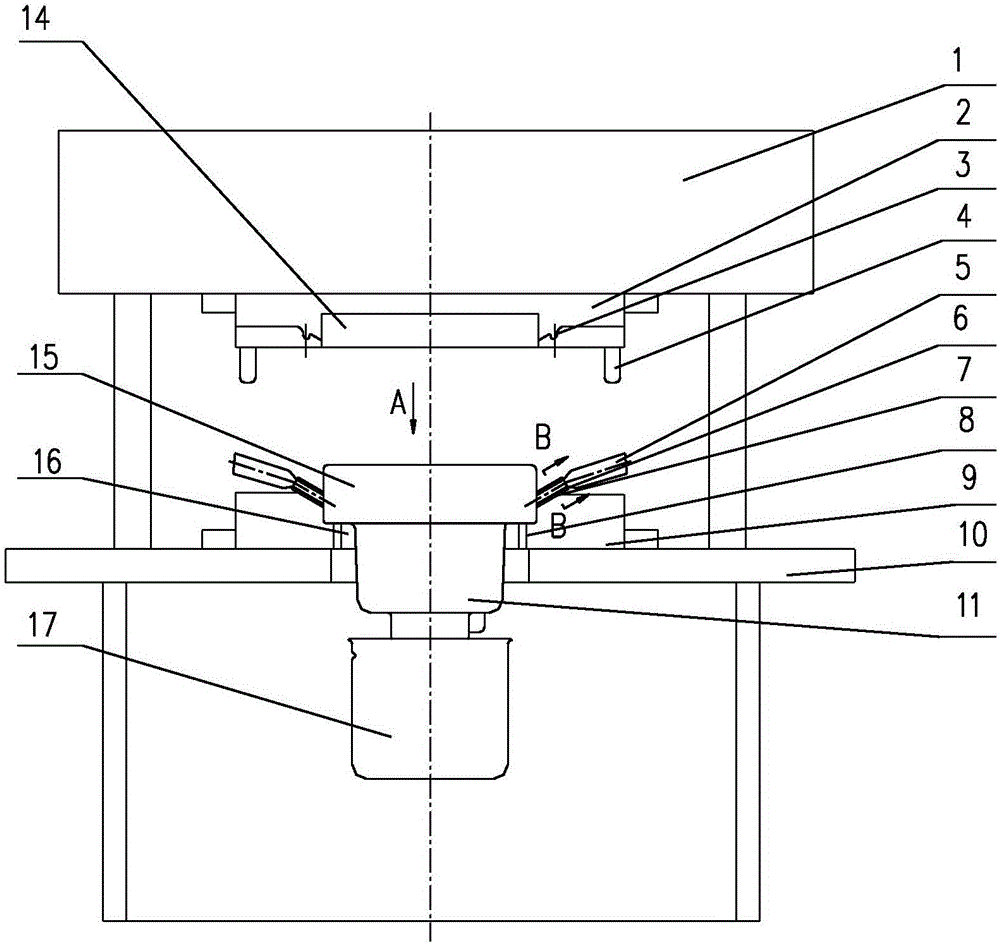

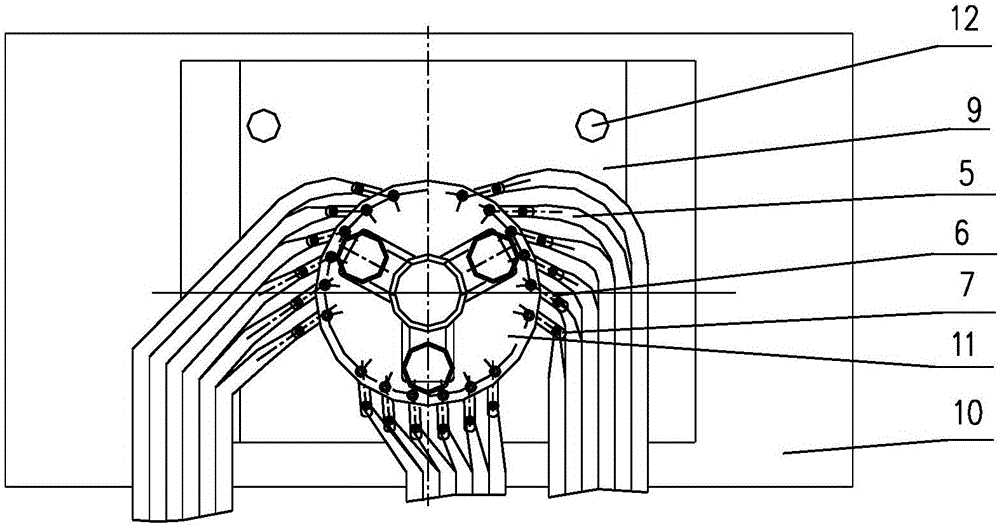

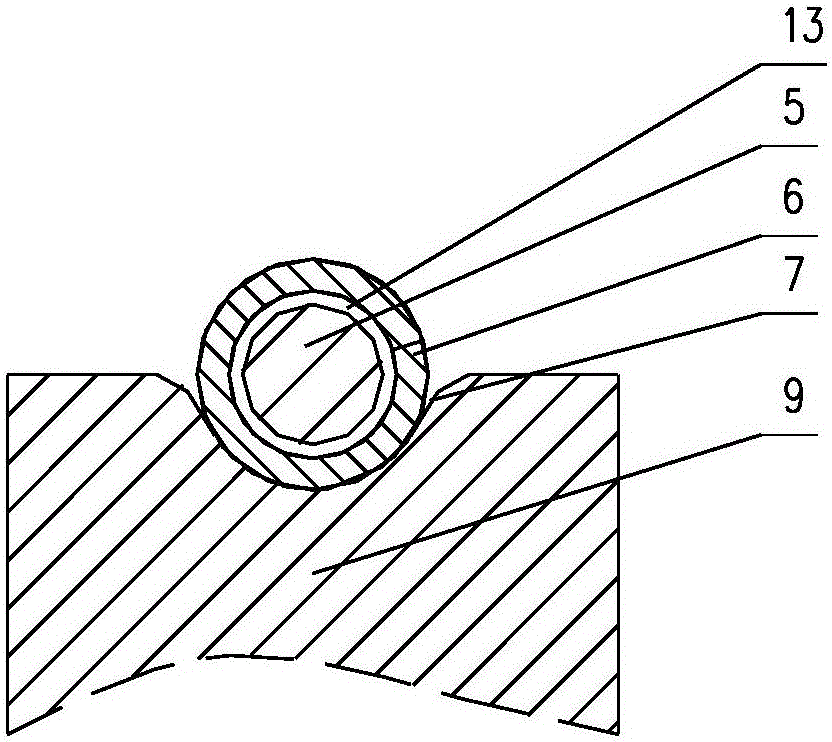

[0021] like Figure 1-2 As shown, the present embodiment provides a tap changer lead cold pressing equipment, which includes a workbench 10, a fixed mold 9, a movable mold 2, and a power unit 1, and a positioning step hole 16 is provided on the fixed mold. The operating end 17 of the switch 11 extends into the positioning step hole 16 of the fixed mold, and the switch seat 15 of the tap changer is inverted on the step surface of the positioning step hole. like image 3 As shown, a plurality of arc-shaped positioning grooves 7 are provided on the fixed mold 9 corresponding to the static contacts, and part (such as one phase) or all of the static contacts 6 of the tap changer are positioned in the positioning grooves 7 of the fixed mold. The movable mold 2 is arranged corresponding to the fixed mold 9, and the corresponding tap switch seat is provided with an accommodating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com